Preparation method of sulfate acacia wood pulp with high bulk and low extract

A bulk and extractable technology, applied in pulp bleaching, cellulose raw material pulping, cellulose pulp post-processing, etc., can solve the problems of low bulk, reduced machine speed and running performance, insufficient degradation, etc. The effect of extractables, optimized bulk, high tensile index

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

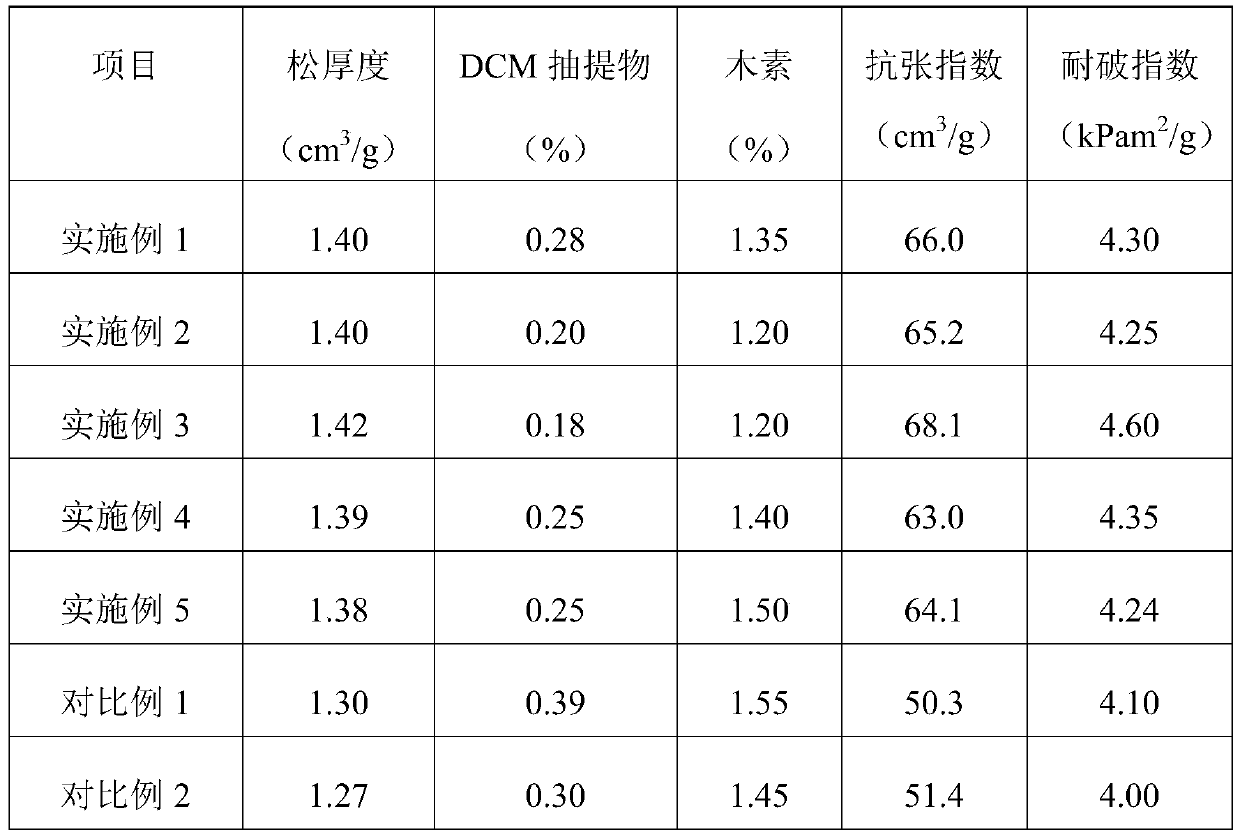

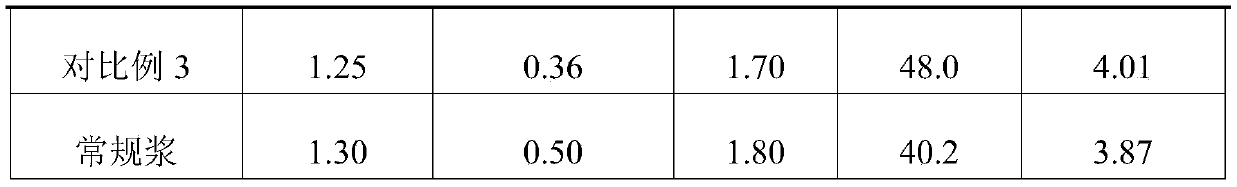

Examples

Embodiment 1

[0026] A kind of kraft acacia wood pulp with high bulkiness and low extractives, its raw wood is composed of the following raw materials in mass percentage: black wattle acacia wood 50% and thick pod acacia wood 50%, the preparation method of the kraft acacia wood pulp, Include the following steps:

[0027] S1. Material preparation: Spray the wood chips with 2ppm of white rot fungus, store them for 10 days, and separate them through the belt conveyor to the air screen or shaker system. Select good chips with a size of 8-65mm and send them to pulping;

[0028] S2. Soaking: Put the wood chips into the pre-preg tower for immersion, the immersion temperature is 85°C, and the time is 40min;

[0029] S3. Cooking: The wood chips and cooking liquid pre-soaked in the pre-soaking tower enter the digesting kettle through the high-pressure feeder for cooking. The cooking white liquor is NaOH and Na 2 The mixed liquor composed of S, the degree of sulfidation of white liquor is 30%, the am...

Embodiment 2

[0039] A kind of kraft acacia wood pulp with high bulkiness and low extractives, its raw wood is composed of the following raw materials in mass percentage: black wattle acacia wood 70% and thick viburnum acacia wood 30%, the preparation method of the kraft acacia wood pulp, Include the following steps:

[0040] S1. Material preparation: Spray wood chips with 5ppm of white rot fungus, store them for 20 days, and separate them through the belt conveyor to the wind screen or shaker system, select good chips with a size of 8-65mm, and send them to pulping;

[0041] S2. Soaking: Put the wood chips into the pre-preg tower for immersion, the immersion temperature is 120°C, and the time is 80min;

[0042]S3. Cooking: The wood chips and cooking liquid pre-soaked in the pre-soaking tower enter the digesting kettle through the high-pressure feeder for cooking. The cooking white liquor is NaOH and Na 2 The mixed liquor composed of S, the degree of sulfidation of white liquor is 35%, the...

Embodiment 3

[0052] A kind of kraft acacia wood pulp with high bulk and low extractives, its raw wood is composed of the following raw materials in mass percentage: black wattle acacia wood 55% and thick viburnum acacia wood 45%, the preparation method of the kraft acacia wood pulp, Include the following steps:

[0053] S1. Material preparation: Spray wood chips with 3ppm of white rot fungus, store them for 15 days, and separate them through the belt conveyor to the air screen or shaker system, select good chips with a size of 8-65mm, and send them to pulping;

[0054] S2. Soaking: Put the wood chips into the pre-preg tower for immersion, the immersion temperature is 102°C, and the time is 60min;

[0055] S3. Cooking: The wood chips and cooking liquid pre-soaked in the pre-soaking tower enter the digesting kettle through the high-pressure feeder for cooking. The cooking white liquor is NaOH and Na 2 For the mixed liquor composed of S, the sulfidation degree of white liquor is 33%, the amo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com