A corrosion-resistant high-performance deformed magnesium alloy and its preparation method

A deformed magnesium alloy, high-performance technology, applied in the field of magnesium alloy materials, to achieve the effect of improving corrosion resistance, promoting uniform corrosion mode, and improving corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

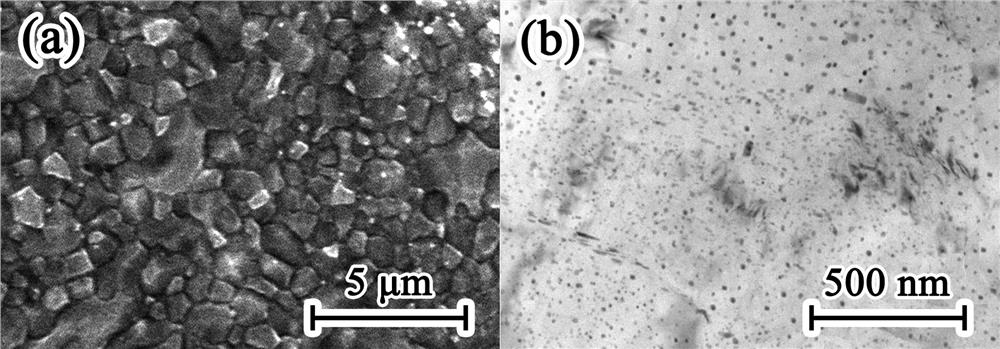

Image

Examples

Embodiment 1

[0028] In this embodiment, the N 2 + 0.15% HFC-125 (vol.%) under the protection of mixed gas, smelt high-purity ZK60 magnesium alloy ingredients according to the normal smelting process (the impurity content of each component is not higher than 1wt.%), after fully dissolving, at 780 ° C Add a Mg-Yb high-purity master alloy (impurity content not higher than 1wt.%) whose Yb content is the final smelted alloy design mass percentage content of 2.0%, use a spiral electromagnetic field to continuously stir for 10 minutes, and keep it at 730°C after melting After 30 minutes to remove the slag, it was poured out of the furnace and cooled naturally to room temperature.

[0029] Subsequently, the ingot was subjected to heat preservation treatment at 450°C×24h in argon gas, and then water-cooled to room temperature to ensure that the second phase was fully re-dissolved into the matrix and the crystal grains were not overheated or burned.

[0030] Reheat the billet after solid solution t...

Embodiment 2

[0033] In this embodiment, the N 2 + 0.15% HFC-125 (vol.%) under the protection of mixed gas, smelt high-purity ZK60 magnesium alloy ingredients according to the normal smelting process (the impurity content of each component is not higher than 1wt.%), after fully dissolving, at 780 ° C Add a Mg-Yb high-purity master alloy (impurity content not higher than 1wt.%) whose Yb content is the final smelted alloy design mass percentage content of 1.8%, use the spiral electromagnetic field to continuously stir for 10min, and keep it at 730°C after melting After 30 minutes to remove the slag, it was poured out of the furnace and cooled naturally to room temperature.

[0034] Subsequently, the ingot was subjected to heat preservation treatment at 450°C×24h in argon gas, and then water-cooled to room temperature to ensure that the second phase was fully re-dissolved into the matrix and the crystal grains were not overheated or burned.

[0035] Reheat the blank after solid solution treatme...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com