Method for separating and purifying mixed-bean pectic polysaccharides

A pectin polysaccharide, separation and purification technology can solve the problems of low separation efficiency, low extraction efficiency, low efficiency, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

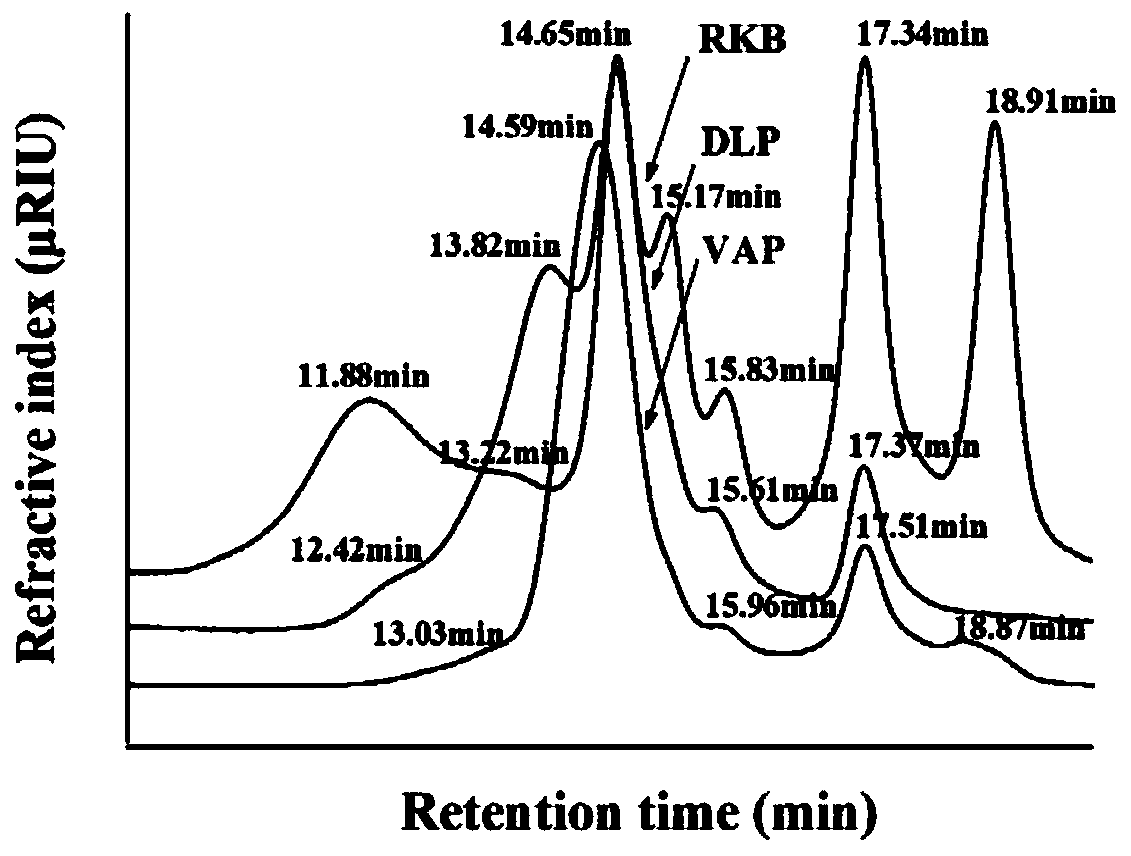

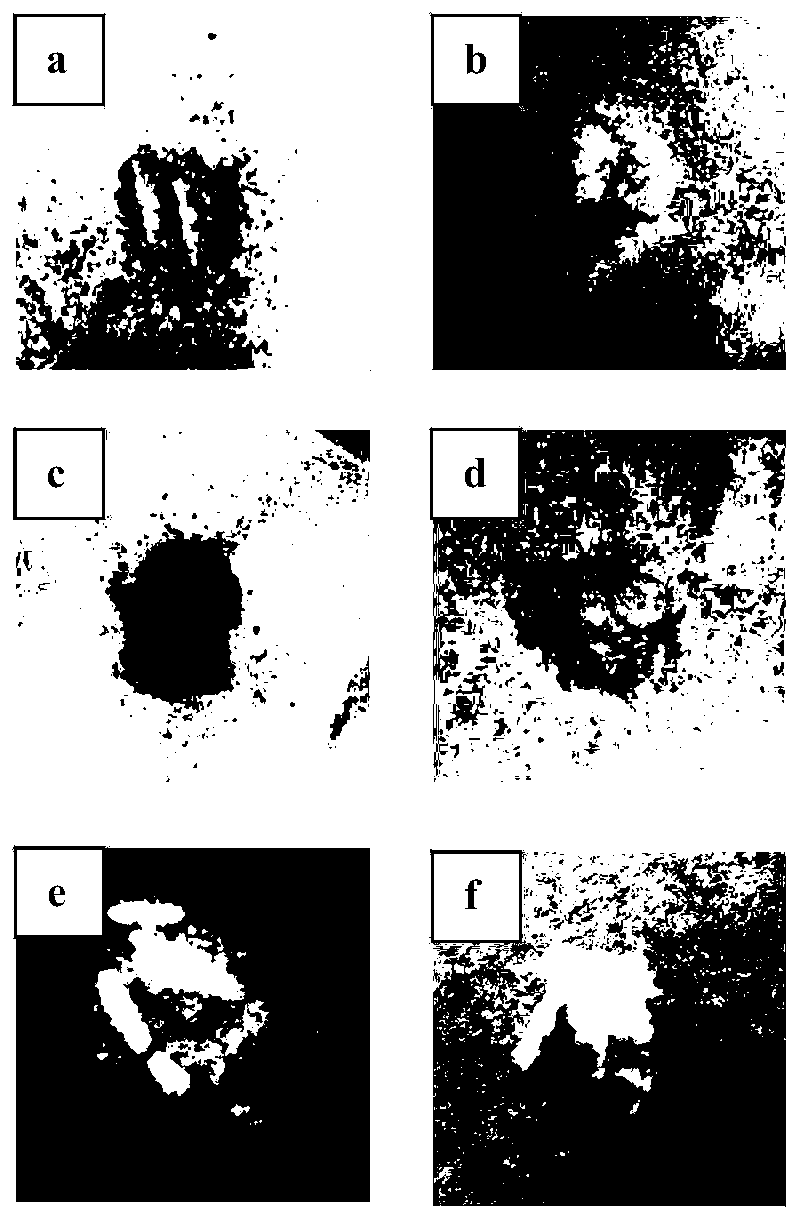

Embodiment 1

[0039] (1) Red bean polysaccharide extraction:

[0040] Process 1000g red bean raw material by ultrafine grinding, collect the fine powder passed through a 250 mesh sieve, add 10L volume concentration ratio of 95% ethanol to soak for 24 hours to degrease, filter and dry, and extract the dried red bean powder with hot water at 95°C for 2 hours twice , combine the extracts, add α-amylase, protease, and glucoamylase in turn for enzymolysis, the enzymolysis conditions are α-amylase at a temperature of 95°C, time 1.5h, protease at a temperature of 60°C, time 0.5h, pH 4.5 , glucoamylase at 60°C, time 0.5h, amylase hydrolyzes starch into dextrin, glucoamylase hydrolyzes dextrin into glucose, protease hydrolyzes protein into polypeptide, inactivates the enzyme at 100°C for 10 minutes, and then Centrifuge at a speed of 8000r / min for 10min, take the supernatant and concentrate it in vacuum, then add 95% ethanol 5.33 times the volume of the concentrated solution, let it stand at 4°C, red...

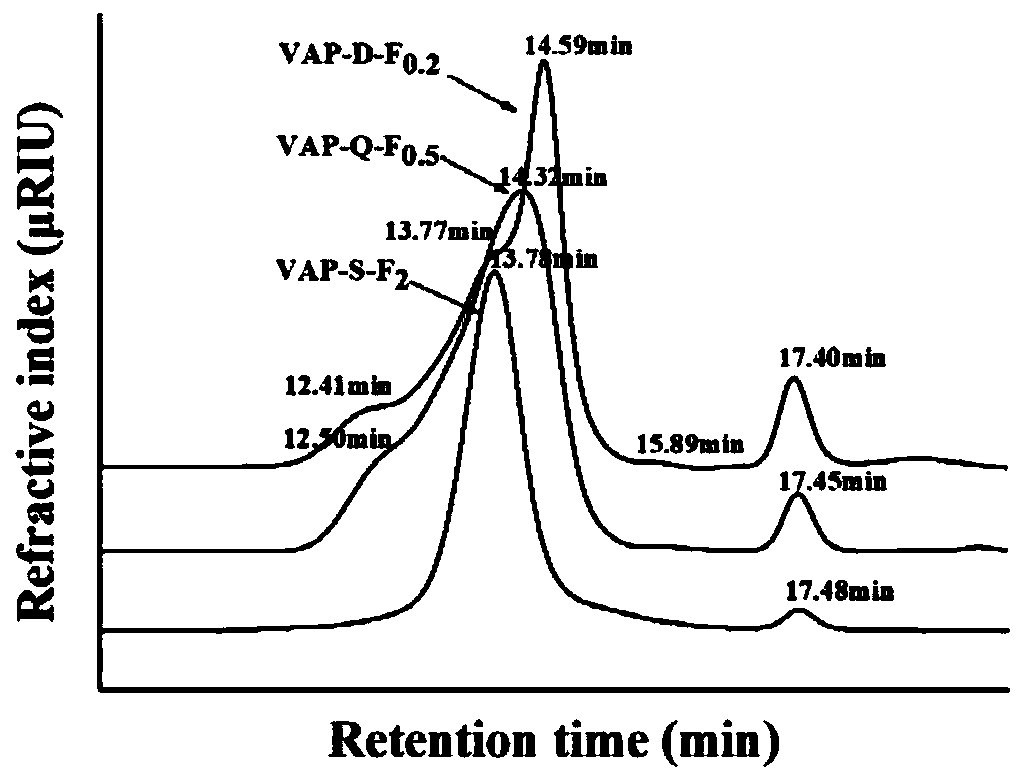

Embodiment 2

[0050] (1) White lentil polysaccharide extraction:

[0051] Process 1000g of white lentil raw material by ultrafine grinding, collect the fine powder passed through a 250-mesh sieve, add 10 L of ethanol with a volume concentration ratio of 95% to soak for 24 hours to degrease, filter and dry, and extract the dried white lentil powder with hot water at 95°C for 2 hours twice , combine the extracts, add α-amylase, protease, and glucoamylase in turn for enzymolysis, the enzymolysis conditions are α-amylase at a temperature of 95°C, time 1.5h, protease at a temperature of 60°C, time 0.5h, pH 4.5 , glucoamylase at 60°C, time 0.5h, amylase hydrolyzes starch into dextrin, glucoamylase hydrolyzes dextrin into glucose, protease hydrolyzes protein into polypeptide, inactivates the enzyme at 100°C for 10 minutes, and then Centrifuge at a speed of 8000r / min for 10min, take the supernatant and concentrate it in a vacuum, then add 95% ethanol 5.33 times the volume of the concentrated soluti...

Embodiment 3

[0061] (1) Red kidney bean polysaccharide extraction:

[0062] Process 1000g of red kidney bean raw material by ultrafine grinding, collect the fine powder passed through a 250-mesh sieve, add 10 L of ethanol with a volume concentration ratio of 95% to soak for 24 hours to degrease, filter and dry, and extract the dried red kidney bean powder with hot water at 95°C for 2 hours twice , combine the extracts, add α-amylase, protease, and glucoamylase in turn for enzymolysis, the enzymolysis conditions are α-amylase at a temperature of 95°C, time 1.5h, protease at a temperature of 60°C, time 0.5h, pH 4.5 , glucoamylase at 60°C, time 0.5h, amylase hydrolyzes starch into dextrin, glucoamylase hydrolyzes dextrin into glucose, protease hydrolyzes protein into polypeptide, inactivates the enzyme at 100°C for 10 minutes, and then Centrifuge at 8000r / min for 10min, take the supernatant and concentrate it in vacuum, then add 95% ethanol 5.33 times the volume of the concentrated solution, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Molecular mass | aaaaa | aaaaa |

| Molecular mass | aaaaa | aaaaa |

| Molecular mass | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com