Ingredient feeding device for lithium battery production

A lithium battery, temporary storage technology, applied in non-aqueous electrolyte batteries, non-aqueous electrolyte batteries, electrolyte battery manufacturing and other directions, can solve the problems of difficult to clean, loss of powdered ingredients, low work efficiency, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Embodiments of the present invention will be further described in detail below in conjunction with the accompanying drawings and examples. The following examples are used to illustrate the present invention, but should not be used to limit the scope of the present invention.

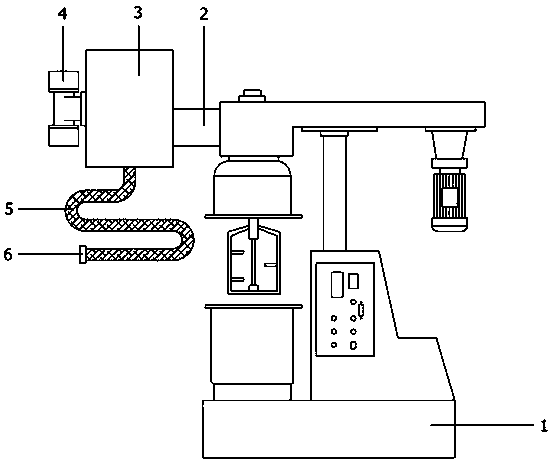

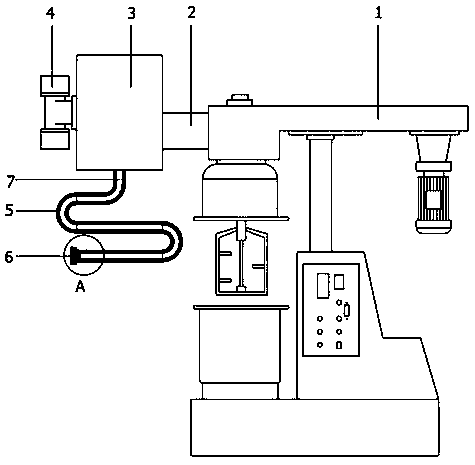

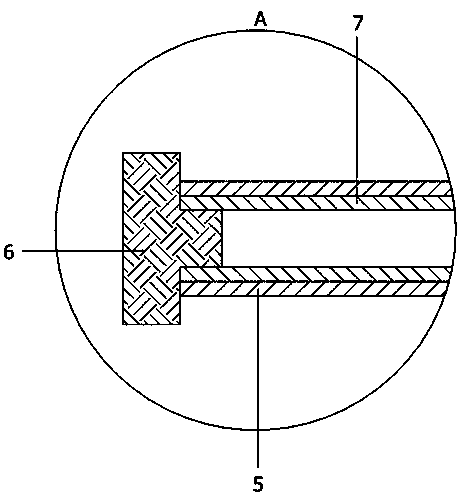

[0028] as attached figure 1 to attach Figure 5 Shown:

[0029] The invention provides a batching and feeding device for lithium battery production, which includes a lifting vacuum mixer 1, a connecting block 2, a temporary batching storage case 3, a circular groove 301, a conical through-hole structure 302, a vibration motor 4, Metal shaping hose 5, rubber sealing plug 6, plastic hose 7, circular rubber sheet 8 and cross opening structure 801; the front side of the lifting end of the lifting vacuum mixer 1 is provided with a temporary storage shell 3 for the ingredients , and the rear end surface of the ingredient temporary storage shell 3 is fixedly connected to the front end surface of the l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com