Method and device for impurity removal and purification of dimethyldichlorosilane by reaction and rectification

A technology of dimethyldichlorosilane and reactive distillation, applied in separation methods, chemical instruments and methods, fractionation and other directions, can solve the problems of large investment and cumbersome process, and achieve high-efficiency separation, high purity, and low equipment investment. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

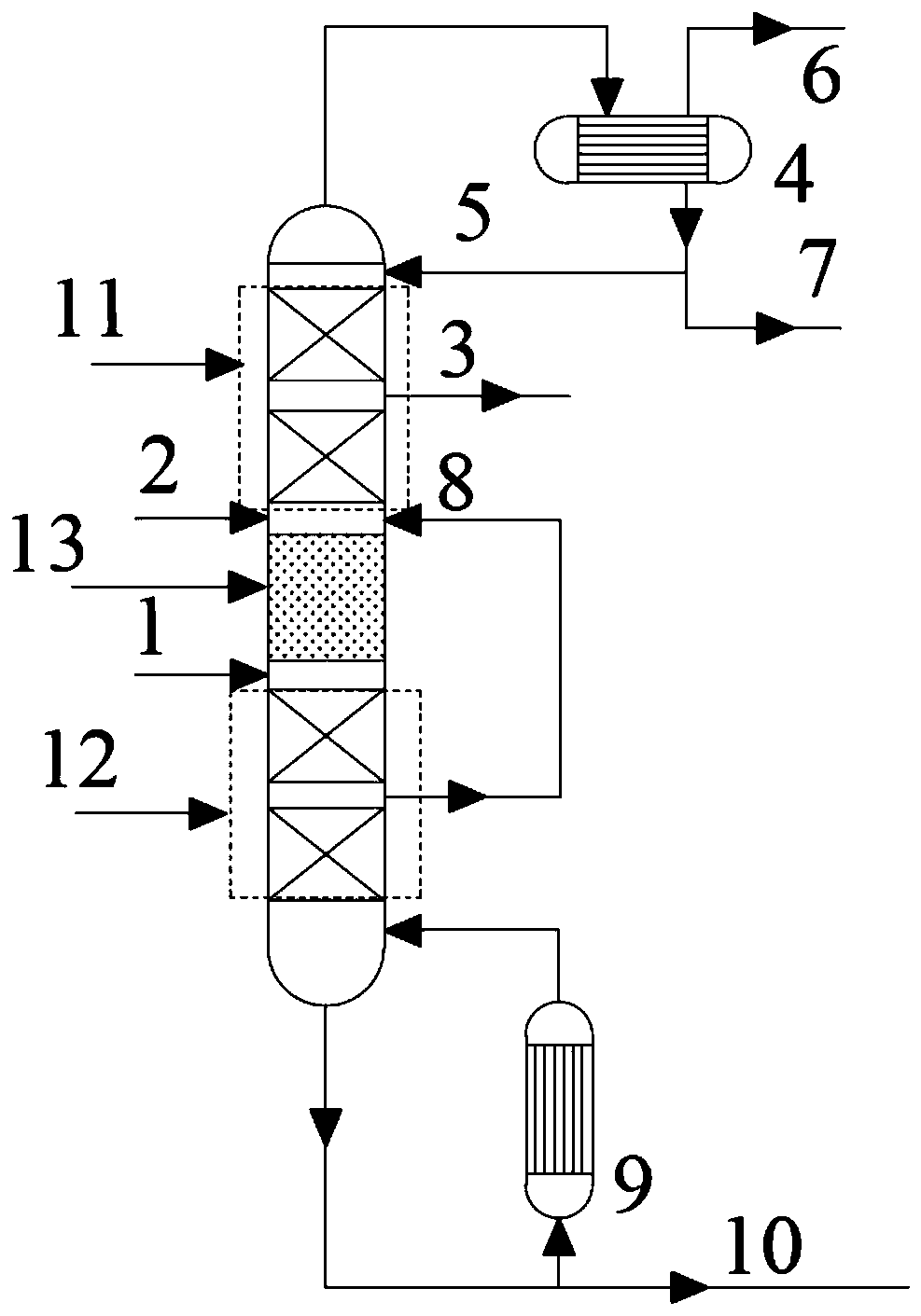

[0036] The crude dimethyldichlorosilane and hexachloroethane enter the reactive distillation column from the upper and lower parts of the reaction section of the reactive distillation column respectively. The reaction section in the column is alternately filled with 1m of wire mesh corrugated packing and structural catalyst from bottom to top. 1m has 4 sections and 8m in total, which plays the role of reactive distillation. The catalyst is a 1% nickel-supported artificial zeolite catalyst, and the number of plates in both the column rectification section and the stripping section is 40. The temperature at the top of the tower is controlled to be between 50°C and 55°C, and the cooling medium of the condenser is circulating water at 28°C. The operating pressure of the reactive distillation column is controlled at 50Kpa, the temperature of the tower reactor is about 90℃, the temperature in the middle reaction section is gradually increased from top to bottom, the temperature in th...

example 2

[0038] The crude dimethyldichlorosilane and chlorobenzene enter the reactive distillation tower from the lower part and the upper part of the reaction section of the reactive distillation tower respectively. The 3 sections of 6m play the role of reactive distillation, the catalyst is a 1% platinum-supported activated carbon catalyst, and the number of plates in both the column rectification section and the stripping section is 40. The temperature at the top of the tower is controlled to be between 50°C and 55°C, and the cooling medium of the condenser is circulating water at 28°C. The operating pressure of the reactive distillation column is controlled at 100Kpa, the temperature of the tower reactor is about 130℃, the temperature in the middle reaction section is gradually increased from top to bottom, the temperature in the reaction section is controlled between 60-70℃, and the reflux ratio at the top of the column is 8. The number of plates in the reactive rectification towe...

example 3

[0039] Example 3: Dimethyldichlorosilane crude material and carbon tetrachloride enter into the reactive distillation tower from the upper and lower parts of the reaction section of the reactive distillation tower respectively, and the reaction section in the tower is alternately filled with wire mesh corrugated packing 1m and 1m from bottom to top. The structural catalyst is 1 m and has 4 sections and 8 m in total, which plays the role of reactive distillation. The catalyst is a 1% palladium-supported alumina catalyst. The temperature at the top of the tower is controlled to be between 50°C and 55°C, and the cooling medium of the condenser is circulating water at 28°C. The operating pressure of the reactive distillation column is controlled at 120Kpa, the temperature of the tower is about 90℃, the temperature of the middle reaction section is gradually increased from top to bottom, the temperature of the reaction section is controlled between 60-70℃, and the reflux ratio at th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com