Natural cooling refrigeration system

A technology of natural cooling and refrigeration system, applied in the directions of refrigerators, refrigeration components, refrigeration and liquefaction, etc., can solve the problems of incapable of compressor cooling, reduction of refrigerant flow, insufficient energy saving, high efficiency and stability of refrigeration system, and achieve the overall design Reasonable, reduce the cooling demand, and improve the effect of natural cooling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

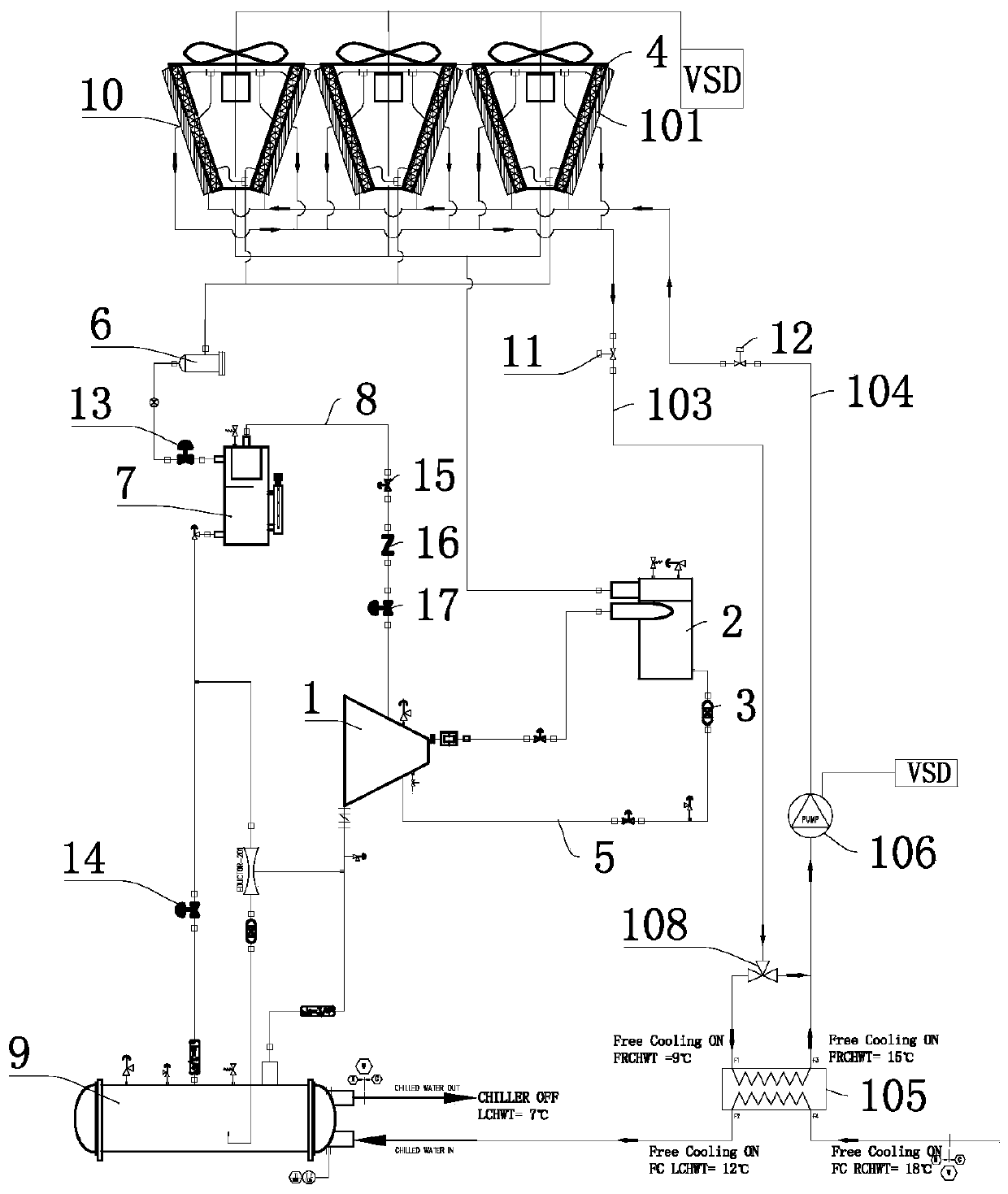

[0029] Embodiment 1: a kind of natural cooling refrigeration system, as figure 1 As shown, the compressor 1 is connected with an oil separator 2, an evaporator 9 and a flash economizer 7 respectively, one end of the oil separator 2 is connected with the air-cooled condenser 4, and the other end is connected with the first filter 3, Compressor 1, oil separator 2, and first filter 3 form a first loop 5, one end of the second filter 6 is connected to the air-cooled condenser 4, and the other end is connected to the flash economizer 7, the flash economizer The compressor 7 communicates with the compressor 1, the compressor 1, the oil separator 2, the air-cooled condenser 4, the second filter 6 and the flash economizer 7 form a second loop 8, and the first-stage electronic expansion valve 13 Installed between the second filter 6 and the flash economizer 7 .

[0030] The flash economizer 7 and the evaporator 9 communicate with each other, and the second-stage electronic expansion v...

Embodiment 2

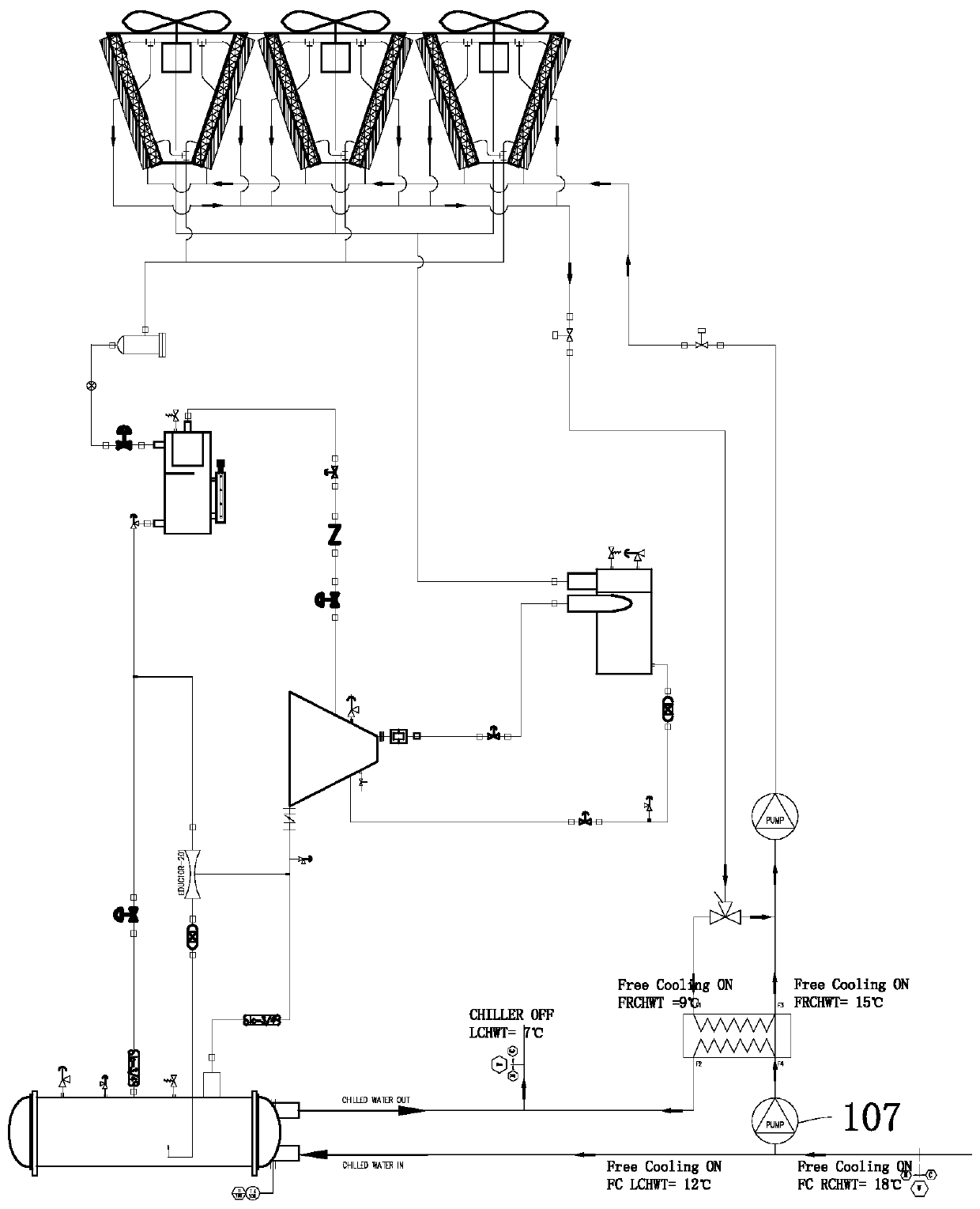

[0037] Embodiment 2: as figure 1 and figure 2 As shown, the water system of the evaporator 9 and the water system of the natural cooling coil 101 are connected in series, and a second water pump 107 is installed on the return water pipe of the evaporator 9 to overcome the water flow of the evaporator 9 through the plate heat exchanger. pressure drop loss.

Embodiment 3

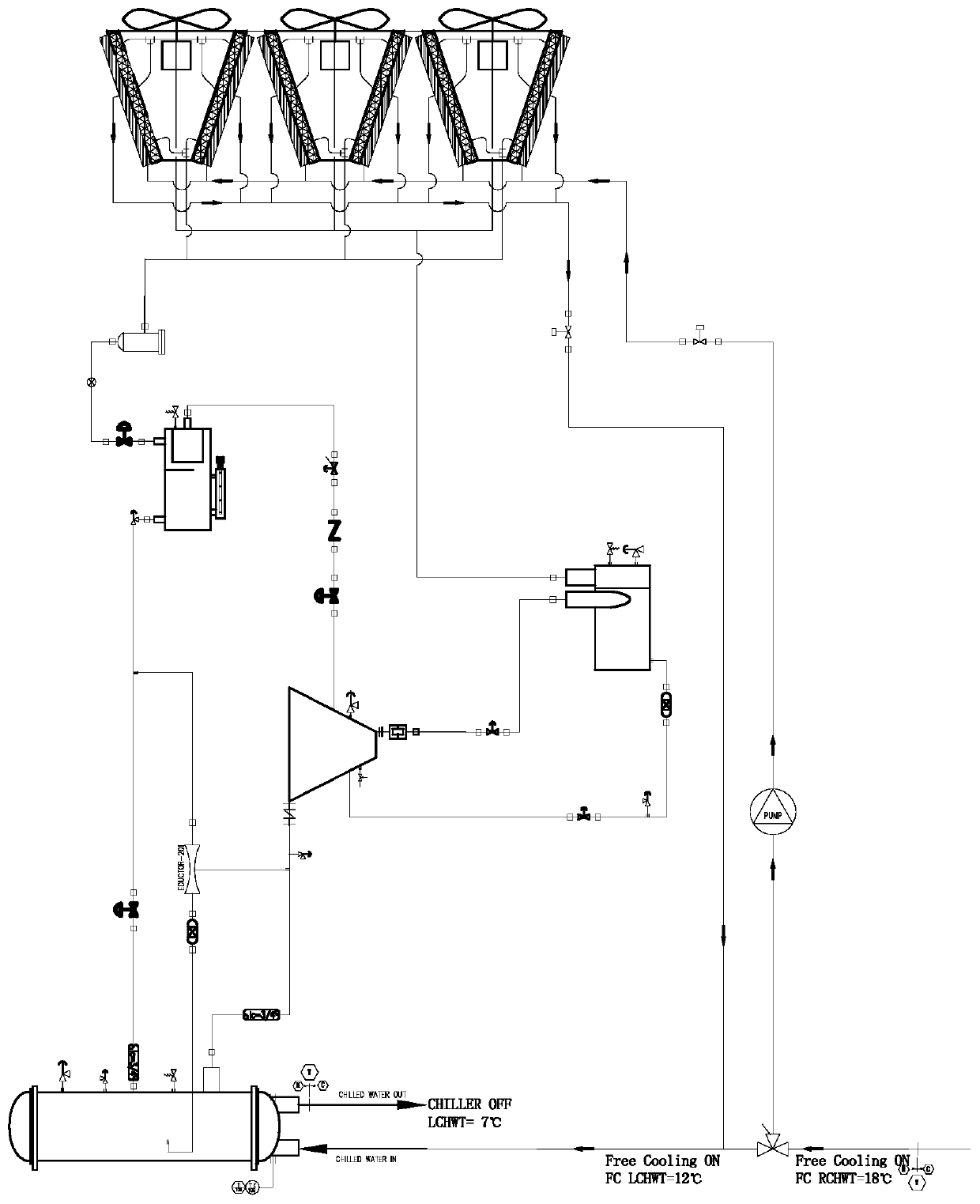

[0038] Embodiment 3: as figure 1 and image 3 As shown, the water system of the evaporator 9 and the water system of the natural cooling coil 101 are connected in series, but the direct connection method is adopted, and the plate heat exchanger is canceled, that is, the two water systems are mixed together, and the linear three-way The valve 108 is connected to the evaporator 9, the first waterway shut-off valve 11 and the second waterway shut-off valve 12, the first water pump 106 is installed between the second waterway shut-off valve 12 and the linear three-way valve 108, and the linear three-way valve 108 is installed on On the water outlet pipeline 104.

[0039] In the water system, the linear three-way valve 108 is used to adjust the water flow into the natural cooling coil 101 to control the heat transfer (cooling capacity) of the natural cooling coil 101. The water system is equipped with a first water pump 106 to overcome the flow through the natural cooling. Pressu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com