Non-ferrous metal cleaning agent and method of cleaning non-ferrous metal part

A non-ferrous metal and cleaning agent technology, used in the field of non-ferrous metal cleaning agent and cleaning non-ferrous metal parts, can solve the problems of corrosion, destruction of atmospheric ozone, flammable and explosive, etc., and achieve the effect of high-efficiency cleaning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

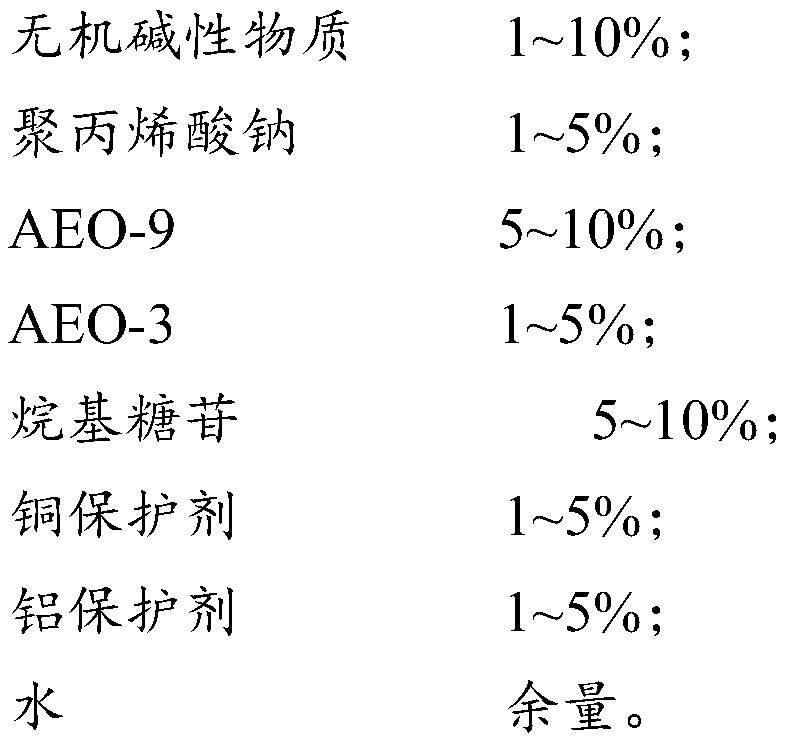

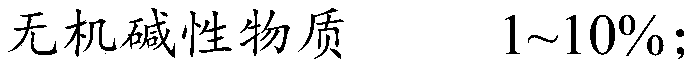

[0049] The components and weight percentages of the non-ferrous metal cleaning agent are: 8% sodium metasilicate pentahydrate, 2% sodium polyacrylate, 10% AEO-9, 2% AEO-3, 10% alkyl glycoside, 2% benzo Triazole, 2% silicone aluminum protectant, 64% water.

Embodiment 2

[0051] The components and weight percentages of the non-ferrous metal cleaning agent are: 10% potassium hydroxide, 5% sodium polyacrylate, 5% AEO-9, 1% AEO-3, 5% alkyl glycoside, 1% benzotriazole , 5% phosphate and 68% water.

Embodiment 3

[0053] The components and weight percentages of non-ferrous metal cleaning agent are: 1% sodium hydroxide, 1% sodium polyacrylate, 9% AEO-9, 5% AEO-3, 9% alkyl glycoside, 2.5% benzotriazole , 2% mercaptobenzotriazole, 1% phosphate and 69.5% water.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com