A method for producing a series of candle special waxes

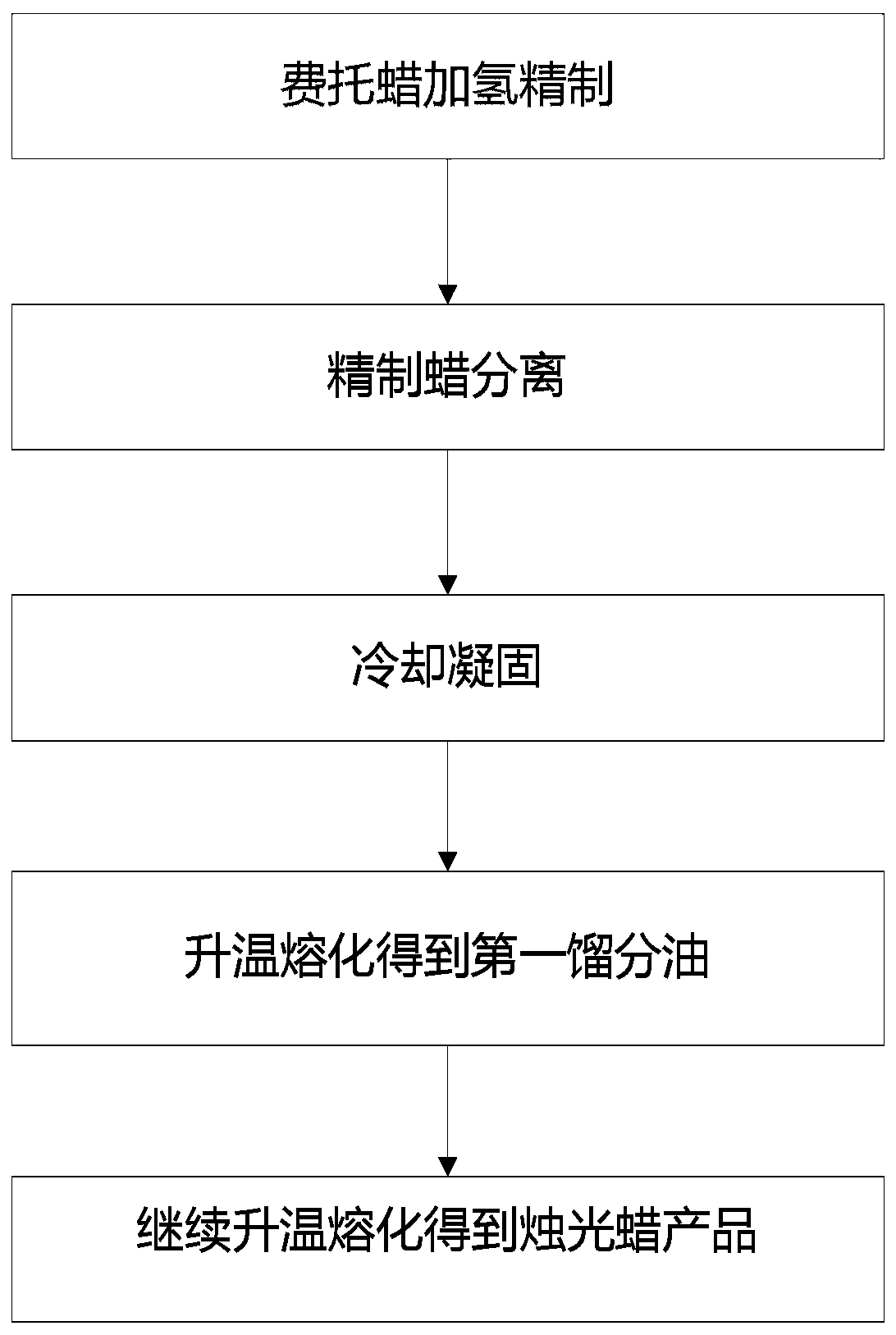

A candle light and series technology, applied in the production of fatty acids, candles, candle components, etc., can solve the problems of harsh operating conditions and potential safety hazards in the production process, and achieve the effects of rich product types, realization of separation effects, and low operating temperature.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] The Fischer-Tropsch synthetic wax obtained by a certain Fischer-Tropsch synthesis process is used as a raw material, and the Fischer-Tropsch refined wax is obtained through hydrogenation refining reaction.

[0032] The Fischer-Tropsch refined wax enters the vacuum rectification tower for separation, the pressure in the tower is 10Pa, and the fractions with a top temperature of 115-150°C, 150-175°C and 175-200°C are collected to obtain 350-400°C, 400- 450°C and 450-500°C fractions.

[0033] The above three fractions are subjected to heating treatment respectively or are mixed into one component according to a certain proportion and then subjected to heating treatment.

[0034] Using 400-450°C as the raw material, melt the distillate wax and put it into a container, cool down to 20°C through natural cooling and cooling water through the heat exchange coil in the container, and then reduce the temperature to 0°C through the programmed cooling device, so that the The feed ...

Embodiment 2

[0038] The Fischer-Tropsch synthetic wax obtained by a certain Fischer-Tropsch synthesis process is used as a raw material, and the Fischer-Tropsch refined wax is obtained through hydrogenation refining reaction.

[0039] The Fischer-Tropsch refined wax enters the thin-film evaporator and the third-stage short-range evaporator in turn for separation. The thin-film evaporator has a pressure of 50pa and a temperature of 140°C to separate the fraction <350°C. The remaining materials enter the first-stage short-range evaporator with an operating pressure of 10Pa. , the operating temperature is 150°C, the 350-400°C fraction is separated, and the remaining material enters the secondary evaporator, the operating pressure is 10Pa, the operating temperature is 175°C, the 400-450°C fraction is separated, and the remaining material enters the third-stage evaporator, , the operating pressure is 10Pa, the operating temperature is 200°C, and the fraction at 450-500°C is separated. The above...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com