Preparation method of mesoporous hollow carbon microspheres with internal communication structure

A technology of hollow carbon and interconnection, applied in the preparation/purification of carbon, hybrid capacitor electrodes, etc., can solve the problems of limited solubilization, affecting the kinetics of polymer polymerization, high film strength, etc., and achieve low Kraft Features, effects of low cmc value and high surface activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

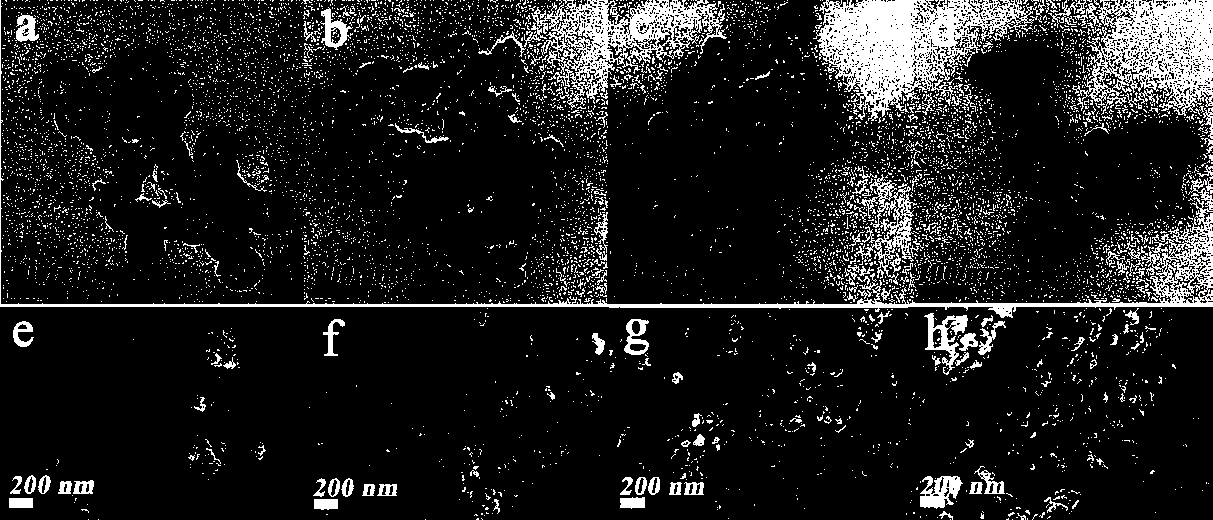

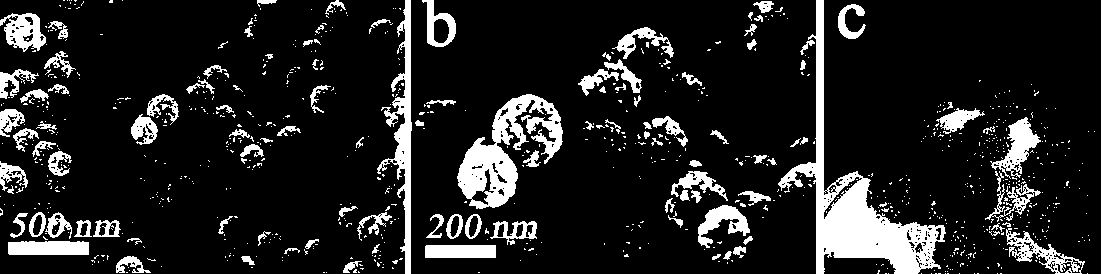

Embodiment 1

[0017] In this example, 1 mass part of 3-aminophenol and 1 mass part of pentane-1,5-bis(dimethylhexadecyl ammonium bromide) were added as cationic Gemini surfactants to 91.7 mass Parts of water and 30 parts by mass of ethanol, the mixture was magnetically stirred in a water bath at 30 °C until it was completely dissolved, then 1 part by mass of concentrated ammonia water (25 wt%) solution was added to the system, and the stirring was continued for ten minutes Add 0.56 parts by mass of formaldehyde, and when the reaction continues until milky white turbidity is formed, add 4.65 parts by mass of tetraethyl orthosilicate, and continue to react in a water bath at 30°C for 24 hours; transfer the reactants after stirring to the reaction kettle , and then the anti-pot was placed in a 100 ° C constant temperature oven for hydrothermal reaction for 24 h. After natural cooling, the product in the reaction kettle was taken out, and washed with distilled water and absolute ethanol in sequ...

Embodiment 2

[0019] In this example, 1 mass part of 3-aminophenol and 0.5 mass part of pentane-1,5-bis(dimethylhexadecyl ammonium bromide) were added to 82 mass parts as cationic Gemini surfactant Parts of water and 20 parts by mass of ethanol, the mixture was magnetically stirred in a water bath at 25 °C until it was completely dissolved, then 0.32 parts by mass of concentrated ammonia water (28 wt%) solution was added to the system, and the stirring was continued for ten minutes Add 0.26 parts by mass of formaldehyde, and when the reaction continues until milky white turbidity is formed, add 2.32 parts by mass of tetraethyl orthosilicate, and continue to react in a water bath at 30°C for 24 hours; transfer the reactants after stirring to the reaction kettle , and then the anti-pot was placed in a 100 ° C constant temperature oven for hydrothermal reaction for 24 h. After natural cooling, the product in the reaction kettle was taken out, and washed with distilled water and absolute ethano...

Embodiment 3

[0021] In this example, 1 mass part of 3-aminophenol and 1.3 mass parts of pentane-1,5-bis(dimethylhexadecyl ammonium bromide) were added to 122 mass parts as cationic Gemini surfactant Parts of water and 13.18 parts by mass of ethanol, the mixture was magnetically stirred in a water bath at 20°C until it was completely dissolved, then 1.98 parts by mass of concentrated ammonia water (25 wt%) solution was added to the system, and the stirring was continued for ten minutes Add 1.06 parts by mass of formaldehyde, and when the reaction continues until milky white turbidity is formed, add 7.6 parts by mass of tetraethyl orthosilicate, and continue to react in a water bath at 25°C for 22 hours; transfer the reactants after stirring to the reaction kettle , and then the anti-pot was placed in a 120 ° C constant temperature oven for hydrothermal reaction for 20 h. After natural cooling, the product in the reaction kettle was taken out, and washed with distilled water and absolute eth...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com