Preparation method and application of magnetic demulsifier capable of simultaneously achieving efficient oil-water separation of O/W and W/O emulsions

A technology of oil-water separation and demulsifier, applied in the field of preparation of magnetic nanoparticles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-1

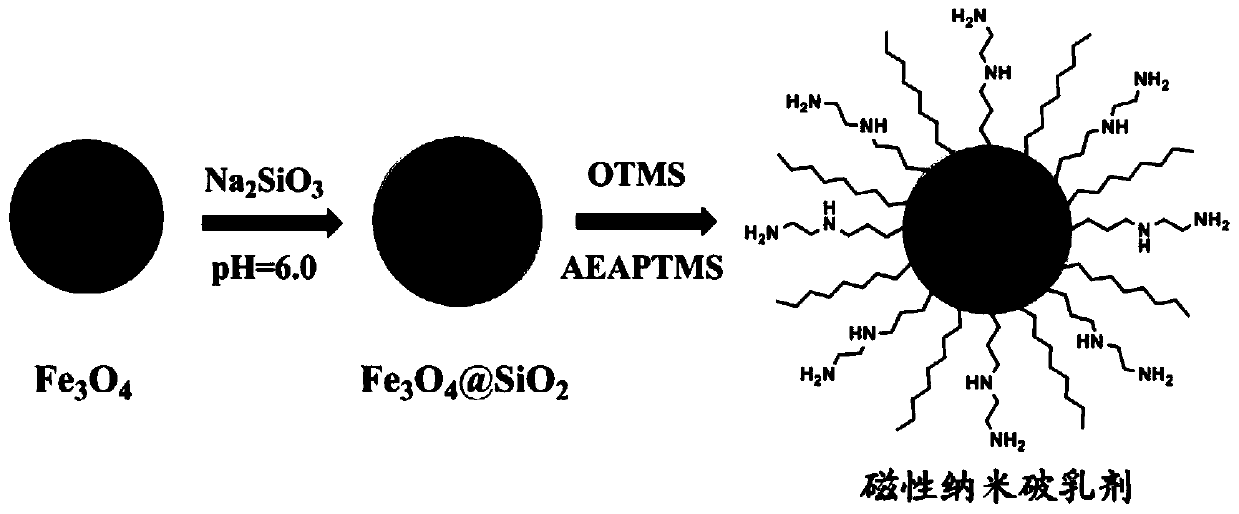

[0030] Example 1-1: Fe 3 O 4 @SiO 2 Nanoparticle preparation

[0031] In a 500mL reactor equipped with a stirrer and a temperature control device, 250mL of 1.5mol / L sodium hydroxide aqueous solution was added, and the temperature was raised to 80℃; then 10.8g of FeCl 3 ·6H 2 O, 4.0g FeCl 2 ·4H 2 O was dissolved in 50 mL of 0.5 mol / L hydrochloric acid aqueous solution, and the solution was added dropwise to the above reactor within 30 minutes under the protection of a nitrogen atmosphere, and the reaction was continued for 1 hour to obtain Fe 3 O 4 Nanoparticles. Take 1.5g of the above Fe 3 O 4 The nanoparticles were dispersed in 300mL deionized water, heated to 80℃ under the protection of nitrogen, and 30mL sodium silicate aqueous solution (1.0mol / L) was added at a constant speed within 2h, and then the reaction was continued for 3h to obtain Fe 3 O 4 @SiO 2 Nanoparticles. The pH value of the whole reaction process is controlled at about 6.0.

Embodiment 2-1

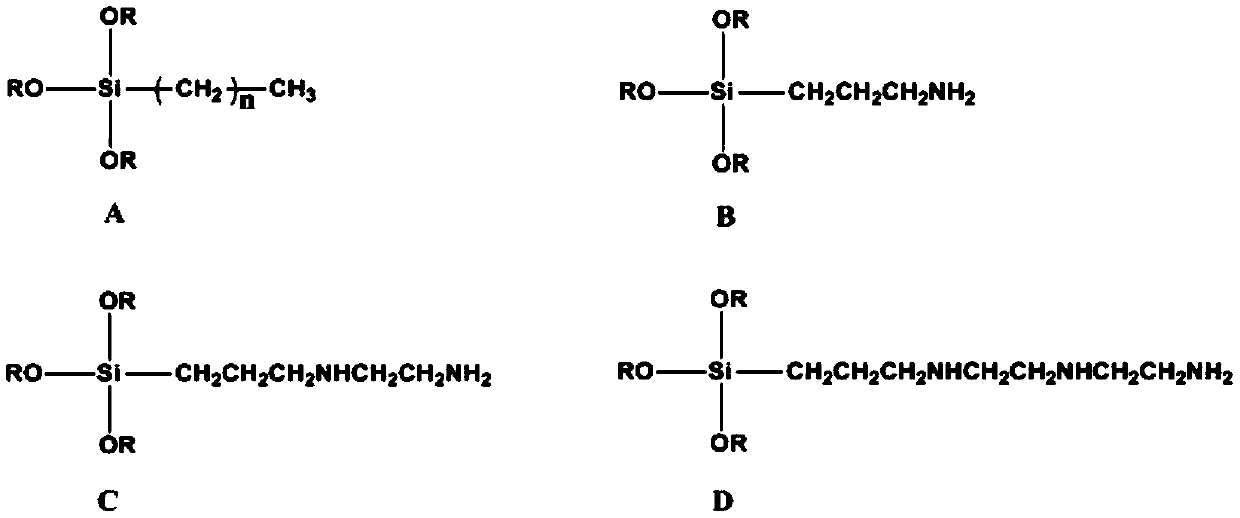

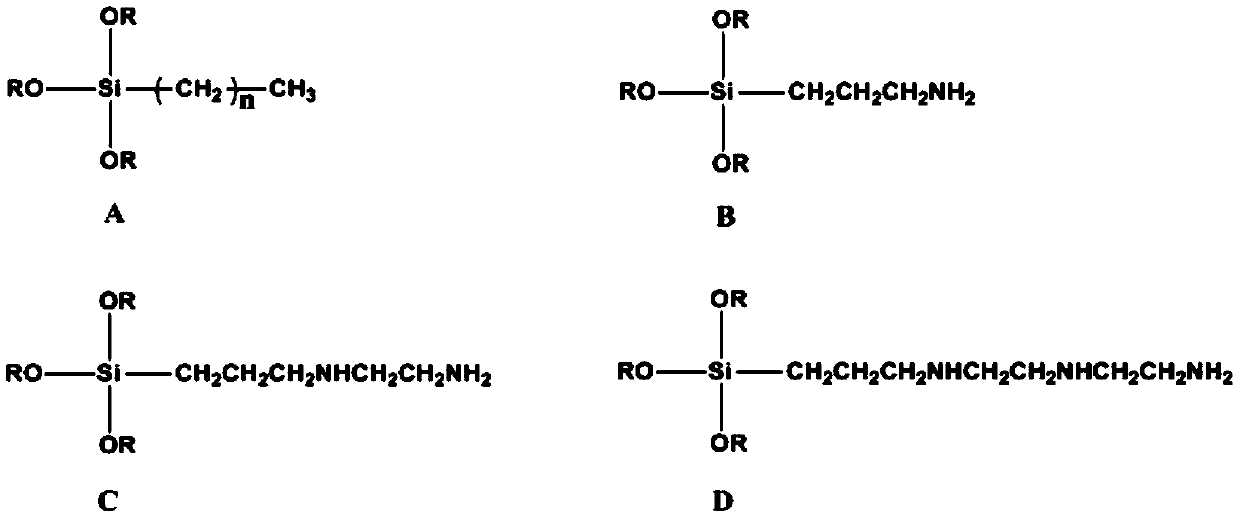

[0042] Take 5.0g Fe 3 O 4 @SiO 2 Nanoparticles were dispersed in 200g ethanol, 0.003mol octyltrimethoxysilane and 0.0015mol aminopropyltriethoxysilane were added under the protection of argon, adjusted the pH value to 12, and reacted for 6h at 40℃ to obtain alkylsilane Mixed and modified magnetic nanoparticles with aminosilane. Add the above-mentioned magnetic nano demulsifier to the O / W emulsion (oil phase is diesel oil, pH=7, oil content is 1.0g / L, average oil droplet size is about 0.5μm), when the demulsifier dosage reaches 200mg / L , The oil removal rate can reach more than 99%. Add the above-mentioned magnetic demulsifier to W / O emulsion (oil phase is diesel oil, water content is 140g / L, and the average size of water droplets is 10.8μm), when the demulsifier dosage reaches 500mg / L, the water removal rate can reach 99% or more . After washing with ethanol, the magnetic nano demulsifier can be recycled up to 7 times.

Embodiment 2-2

[0044] Take 5.0g Fe 3 O 4 @SiO 2 Nanoparticles are dispersed in a mixed solution of 160g ethanol and 40g water, add 0.003375mol butyltrimethoxysilane and 0.001125mol aminopropyltriethoxysilane under the protection of argon, adjust the pH value to 7, and react at 50℃ For 48 hours, the magnetic nanoparticles modified by mixing alkylsilane and aminosilane are obtained. Add the above-mentioned magnetic nano demulsifier to the O / W emulsion (oil phase is soybean oil, pH=11, oil content is 1.0g / L, average oil droplet size is about 0.4μm), when the demulsifier dosage reaches 310mg / L When, the oil removal rate can reach more than 99%. Add the above magnetic demulsifier to the W / O emulsion (oil phase is soybean oil, water content is 140g / L, and the average water droplet size is 6.8μm). When the demulsifier dosage reaches 710mg / L, the water removal rate can reach 99% the above. After washing with n-hexane and ethanol, the magnetic nano demulsifier can be recycled up to 6 times.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com