Automatic sheet arranging machine for packaging sheet materials

A technology of packaging chips and automatic discharge, which is applied in the direction of conveyor objects, transportation and packaging, electrical components, etc., can solve the problems of restricting the processing efficiency of semiconductor electrical components, affecting the automatic chip discharge machine, and the mutual extrusion of package chips. Achieve the effect of reducing the manual participation rate, smooth nesting, and ensuring the correct swing direction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In the following, the present invention will be further described in conjunction with the accompanying drawings and specific embodiments, so as to understand more clearly the technical idea claimed in the present invention. It is only stated here that the words for directions such as up, down, left, right, front, back, inside, and outside that appear or will appear in the text of the present invention are only based on the accompanying drawings of the present invention, and are not specific to the present invention. limited.

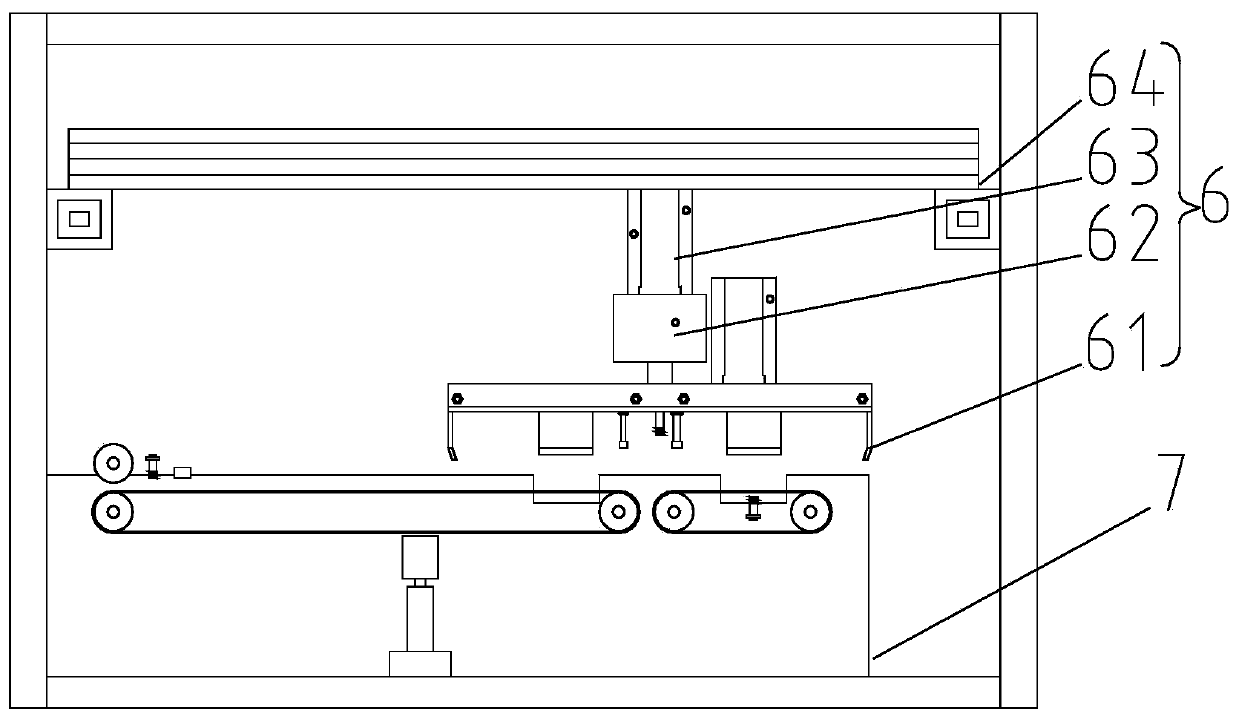

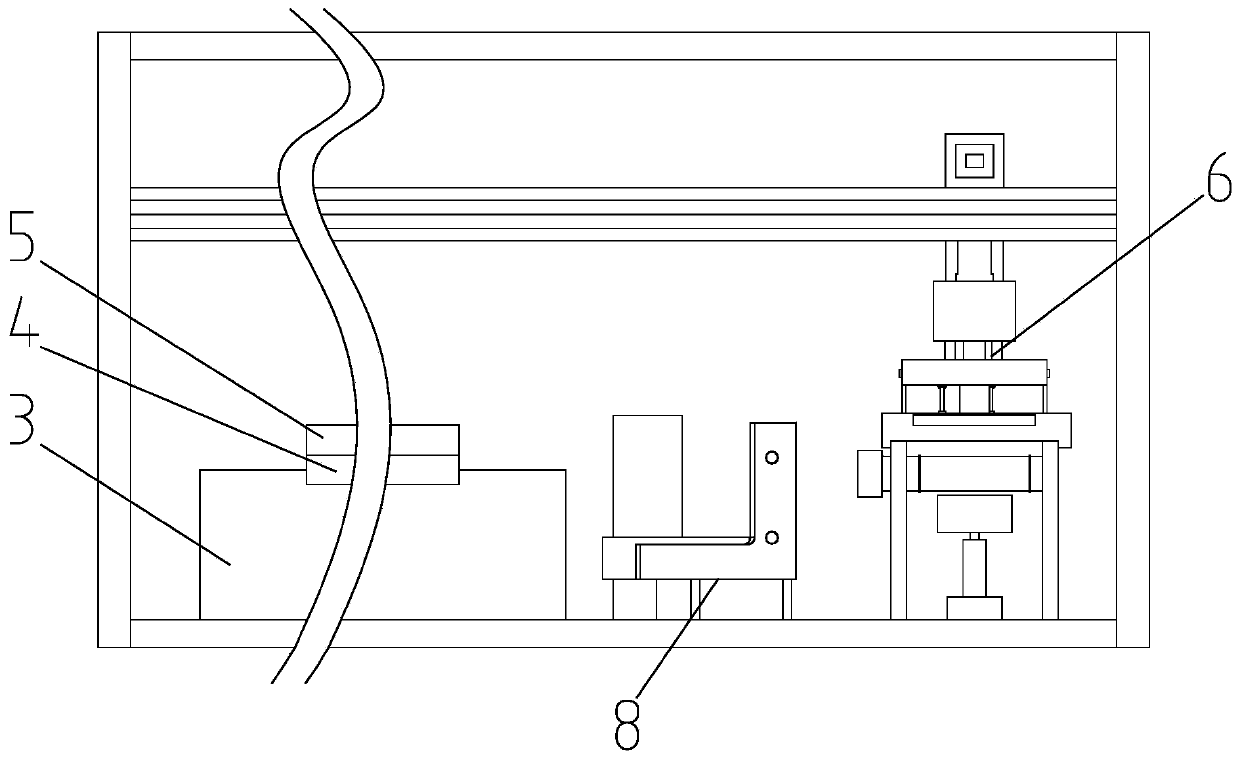

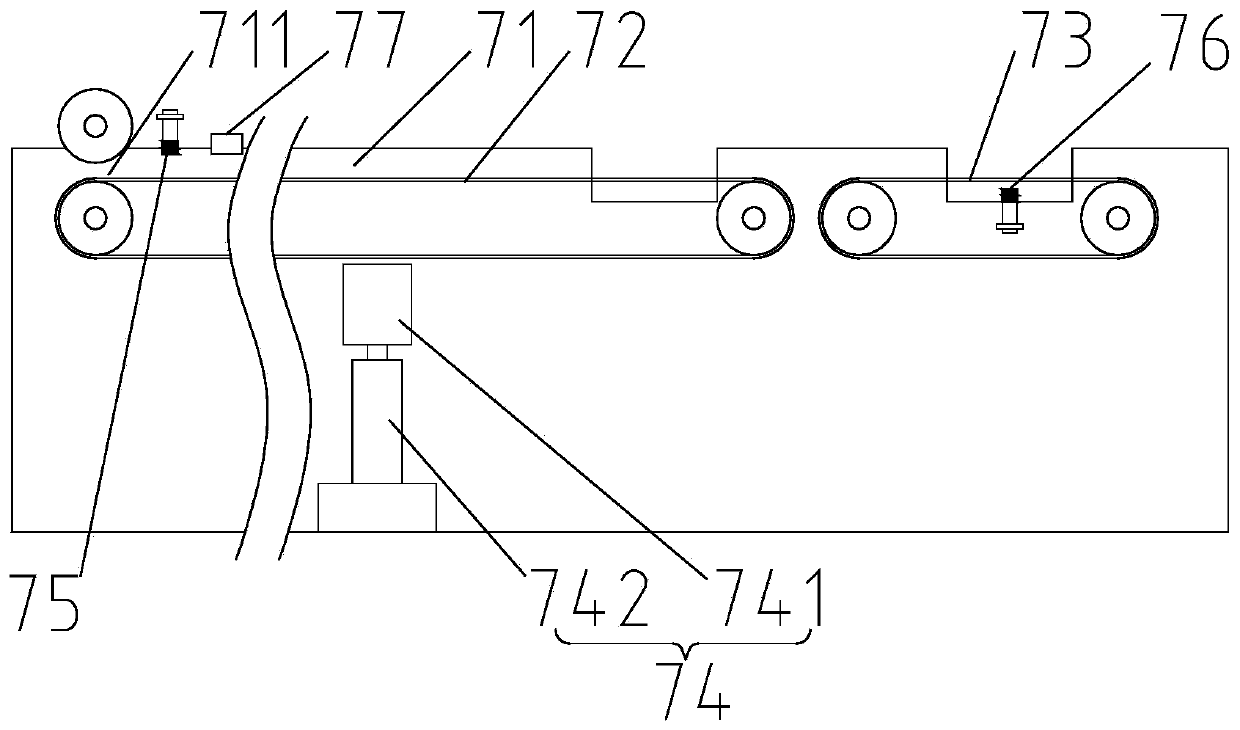

[0026] like Figure 1-3 As shown, an automatic chip unloading machine for packaged sheets 1 in the embodiment of the present invention includes a workbench 3, a clamping chassis 4 placed on the workbench 3, and is used to cooperate with the clamping chassis 4 to place the packaged pieces The clamping top frame 5 clamped by the material 1 and the material shifting device 6 for moving the packaging sheets 1 to the corresponding positions of the cla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com