Yellow peel treatment process and yellow peel treatment equipment for quartz mine or alkalifeldspar mine

A treatment process and treatment equipment technology, applied in the field of yellow skin treatment process and equipment, can solve the problems of increasing the difficulty of exhaust gas treatment, high water consumption, and high operating costs, reducing cleaning water consumption, improving removal efficiency, and avoiding equipment. effect of input

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

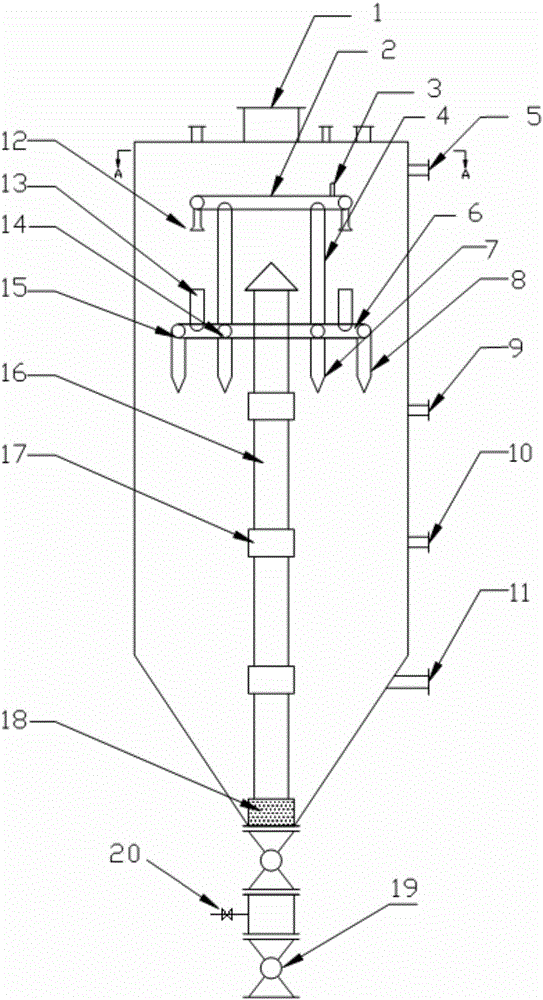

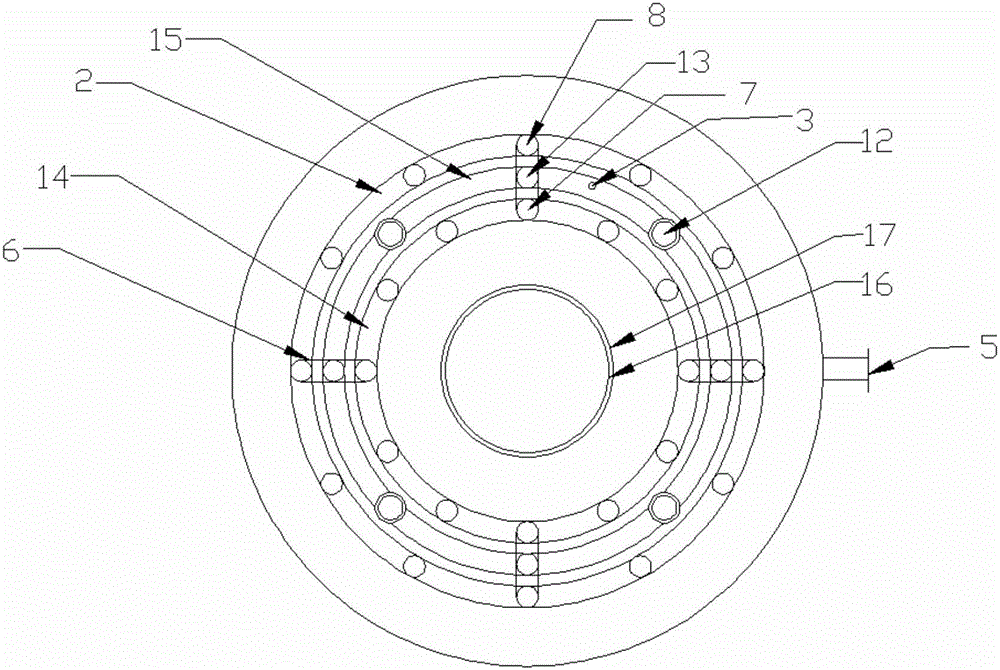

[0043] The yellow bark processing equipment of quartz ore or potash sodite ore soaks and cleans the kettle, and its center pipe 16 is made of multi-section round pipes connected by straight joints 17 .

[0044] Use yellow skin treatment equipment of the present invention to soak, the step of cleaning of quartz ore is:

[0045] (1) Pull the first vibrating ring 14 and the second vibrating ring 15 to the top of the central tube 16 with a rope, and connect and install the multi-section circular tubes of the central tube 16 through the straight joint 17;

[0046] (2) Crushing the quartz ore to a particle size of 10mm to 20mm, the crushed quartz ore particles are input into the rotary kiln drying cylinder and heated in reverse with the hot air after heat exchange, and the quartz ore particles are heated to 150°C;

[0047] (3) Add the hydrochloric acid after soaking the quartz ore particles in the immersion cleaning kettle, and the hydrochloric acid concentration in this kettle is a...

Embodiment 2

[0054] Except that in the (2) step, the quartz ore particles are heated to 180°C, the hydrochloric acid in the kettle in the 3rd step regulates the mass concentration to be 24%, the liquid level of the (4) step hydrochloric acid is 250mm higher than the quartz ore particle top surface, (5) In the step, the cleaning wastewater is neutralized to pH=8 and then the ore particles are cleaned by the clear water after pressure filtration, until the pH of the cleaning water sampled from the first detection port 9 is 6.2 and the first detection port 9 Except that the ore particles above the same level are transferred to the unloading stage, all the other steps are the same as in Example 1.

Embodiment 3

[0056]Except that in the (2) step, the quartz ore particles are heated to 210°C, in the third step, the concentration of hydrochloric acid in the kettle is adjusted to be 26%, the liquid level of the (4) step hydrochloric acid is 300mm higher than the top surface of the quartz ore particles, (5) In the step, the cleaning waste water is neutralized to pH=9 and then the clear water after the press filter is used to clean the quartz ore grains, until the pH of the cleaning water of the cleaning water sampled from the first detection port 9 is 6.5 Except that the quartz ore particles above the same level as the first detection port 9 are transferred to the unloading stage, all the other steps are the same as in Embodiment 1.

[0057] In the applicant's experiment, a polypropylene pipe with a diameter of 500mm was used as the wall of the soaking and cleaning kettle, and a polypropylene pipe with a diameter of 110mm was used as the center pipe. figure 1 , 2 Make a Soaking Wash Kett...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com