Autonomic feeding system

A feeding system and material mixing technology, which is applied in the direction of unloading devices, chemical instruments and methods, and sales of raw material supply devices, etc., can solve the problems of less manual operation steps, more manual operation steps, and unsmooth transportation, so as to reduce equipment costs , Increase the effect of mixing uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

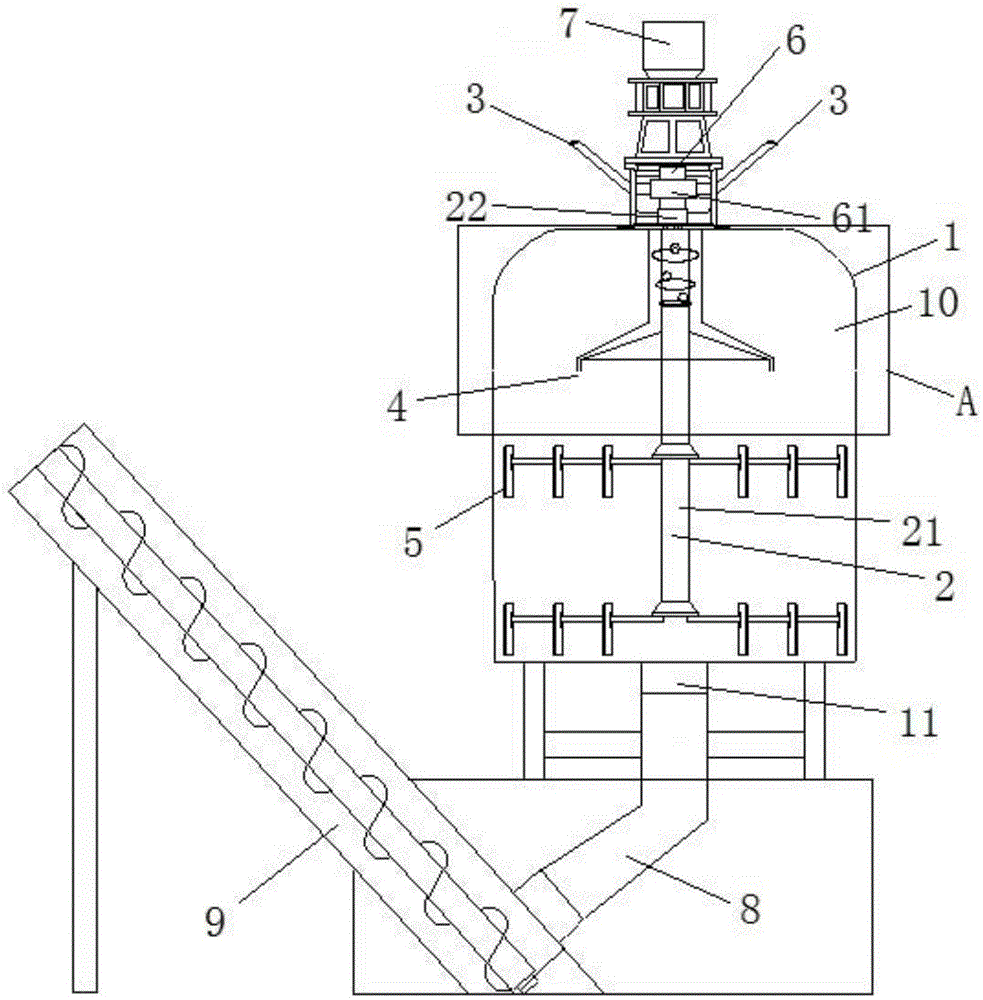

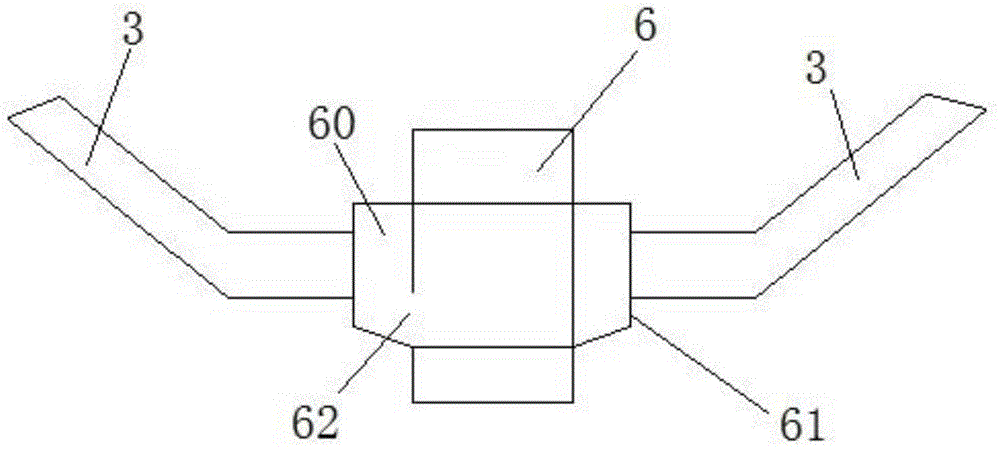

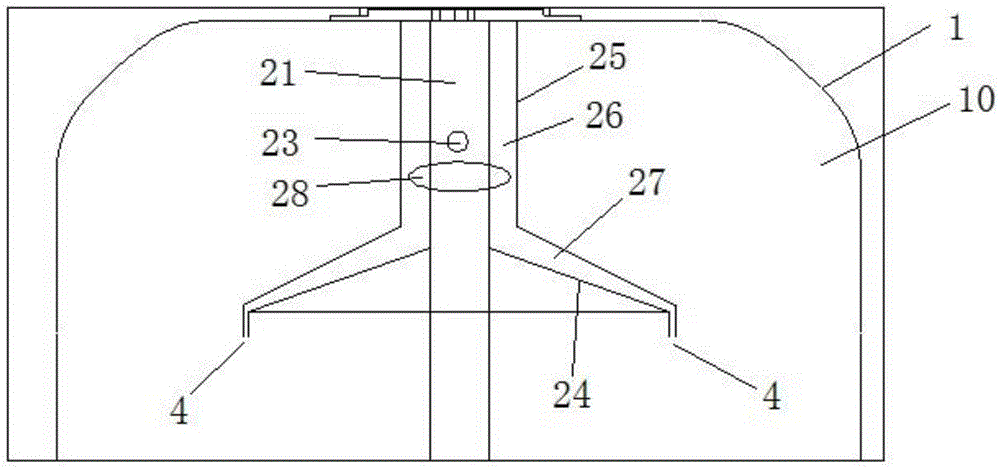

[0043] This embodiment provides an automatic feeding system, such as Figure 1-3 As shown, it includes: a mixing chamber 1 with a stirring space 10, the bottom is provided with a discharge port 11 communicating with the stirring space 10; a drum 2 is rotatably installed on the mixing chamber 1, and has a The first section 21 inside the stirring space 10 and the second section 22 protruding upwards from the stirring space 10, and the second section 22, and the part connected to the second section 22 inside the first section 21 A drum inner cavity is provided; a motor 7 is connected to the drum 2 through a connection structure, and is used to drive the rotation of the drum 2; there are at least two feeding pipes 3, which are connected to the drum 2 through the connection structure. The inner cavity of the drum is connected to deliver raw materials to the inner cavity of the drum; the discharge port 4 is set at a certain distance from the outer wall of the first section 21, and i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com