High-efficiency and energy-saving material grinder

A high-efficiency and energy-saving pulverizer technology, which is applied in the field of material crushing devices and high-efficiency and energy-saving material pulverizers, can solve the problems of being unable to adjust the gap, reduce production efficiency, and increase energy consumption at will, so as to reduce a large amount of invalid workload and stabilize Product quality, the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

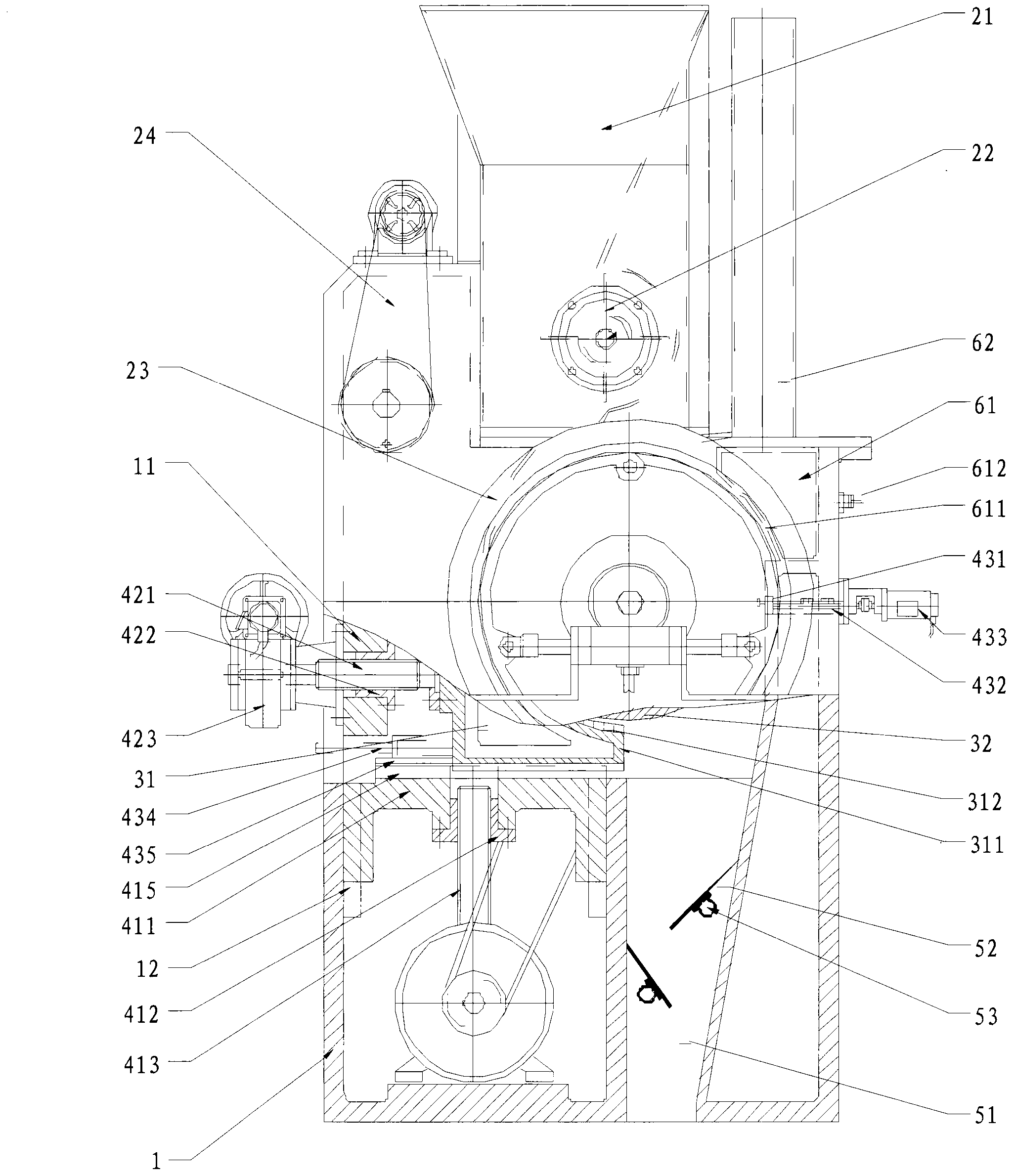

[0028] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

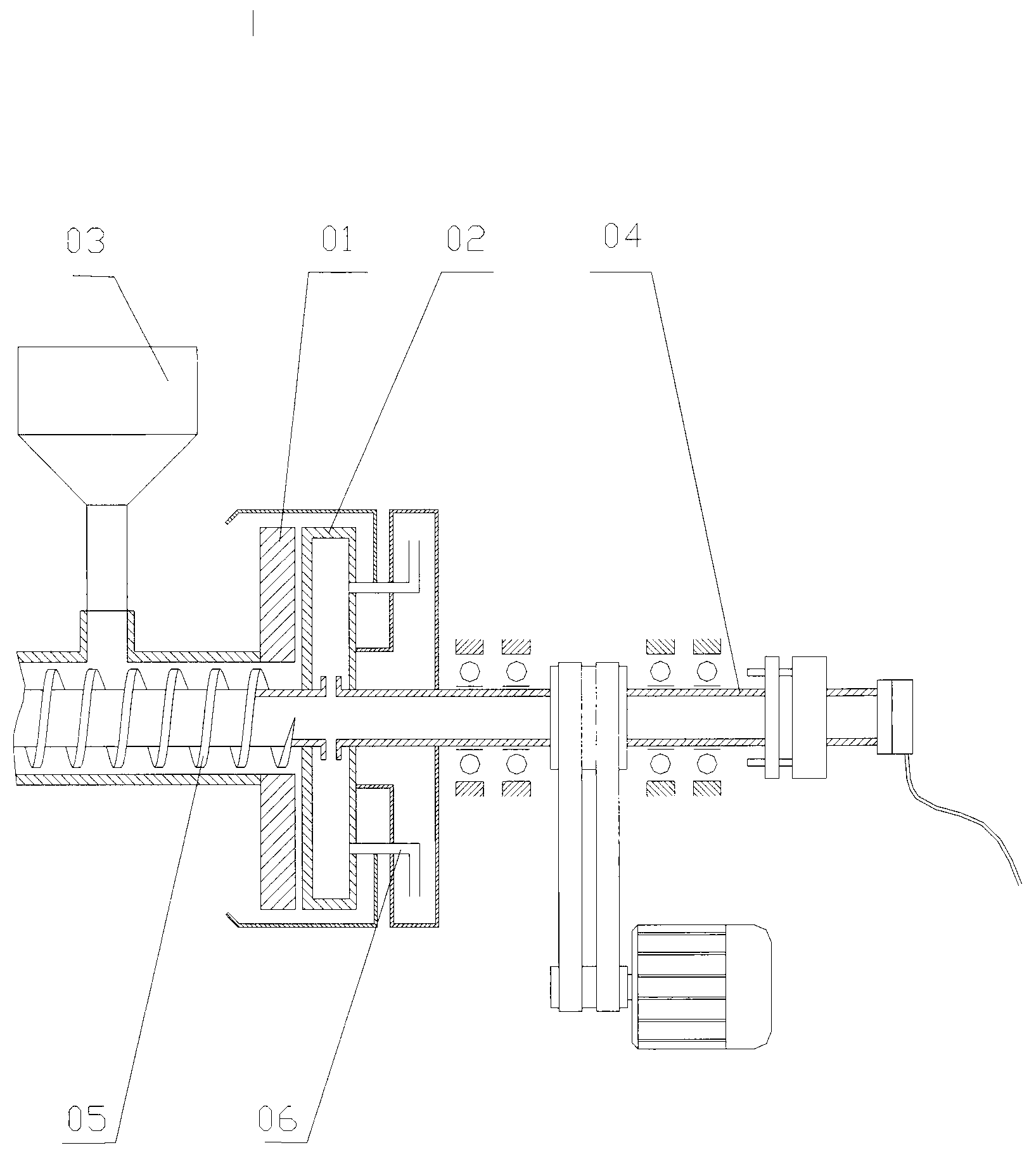

[0029] see figure 2 , The high-efficiency and energy-saving material pulverizer of the present invention includes a frame 1, a feeding mechanism, a cutter part, a cutter adjustment device, a discharge device and an air cooling device.

[0030] The left side wall of the frame 1 is provided with a support and reinforcement wallboard 11 for installing the tool adjustment device. The thickness of the support and reinforcement wallboard 11 is 50-500 mm, and the height is 50-600 mm. Its strength and rigidity are much higher than The side wall of the frame 1, the way to support and reinforce the wallboard 11 to be fixed on the frame 1 can be a detachable connection or a non-detachable connection.

[0031] The cutter part is located in the middle of the frame 1 and includes a fixed cutter seat 31 and a rotating movable cutter roller 32 . The fixed knife se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com