A kind of room temperature self-healing coating and preparation method thereof

A self-healing, room temperature technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0054] A room temperature self-healing coating, comprising the following raw materials in parts by weight:

[0055] 60 parts of self-healing polythiourethane matrix;

[0056] 25 parts of photocurable resins composed of bisphenol A epoxy diacrylate and aliphatic polyurethane triacrylate in a mass ratio of 3:2;

[0057] 10 parts of photocurable monomer diluents composed of trimethylolpropane triacrylate, tripropylene glycol diacrylate, and butyl acrylate in a mass ratio of 4:3:3;

[0058] 5 parts of photoinitiator BP.

specific Embodiment 2-6

[0059] Specific embodiment 2-6, other are with specific embodiment 1, difference is following table:

[0060]

[0061]

[0062] The self-healing polythiourethane used in the above-mentioned embodiments 1-6 is prepared by the following method:

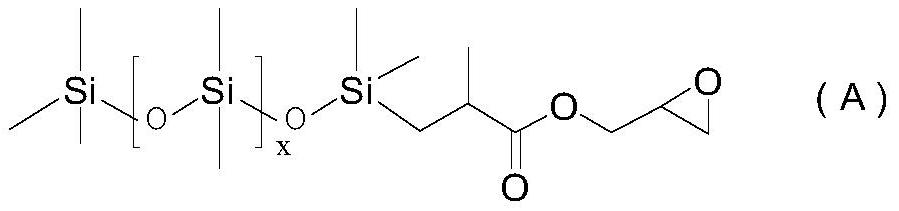

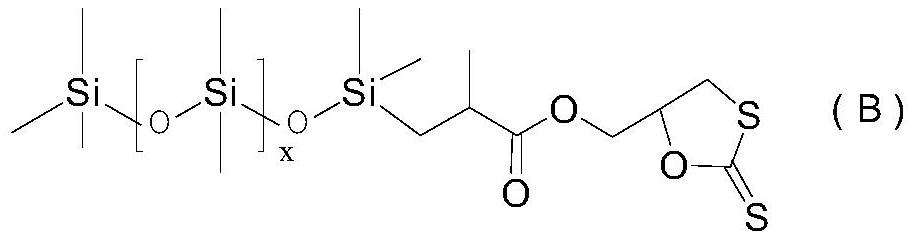

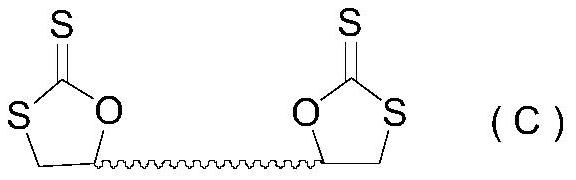

[0063] (1) 1 part of one-end hydrogen-containing siloxane was dissolved in 50 parts of tetrahydrofuran, 1.1 parts of glycidyl methacrylate, 1 wt% of hydroquinone, 10 -5 10 parts of chloroplatinic acid, dissolved in 10 parts of tetrahydrofuran and added to the constant pressure dropping funnel, the dropping speed was controlled, stirred, and reacted at 60°C for 5 hours, the solvent was distilled off under reduced pressure, and 30 parts of toluene, excess sodium bicarbonate and 10 parts of Deionized water, stirred at 60°C for 3h, separated the water phase, took the organic layer, and distilled off the solvent under reduced pressure to obtain a siloxane-modified epoxy monomer (IR: 1642cm -1 : C=C disappeared; 1718cm -1 : C=O exists...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com