Space-time function-controlled multi-section linkage type continuous casting magnetic stirring system and method thereof

A magnetic stirring and linkage technology, applied in the field of iron and steel metallurgy, can solve the problems of limited homogeneity and density, inconsistent thickness and thermal state of the billet shell, and narrow process control window, so as to improve the metallurgical function and effect, overcome the effect The effect of short time and flexible working mode

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

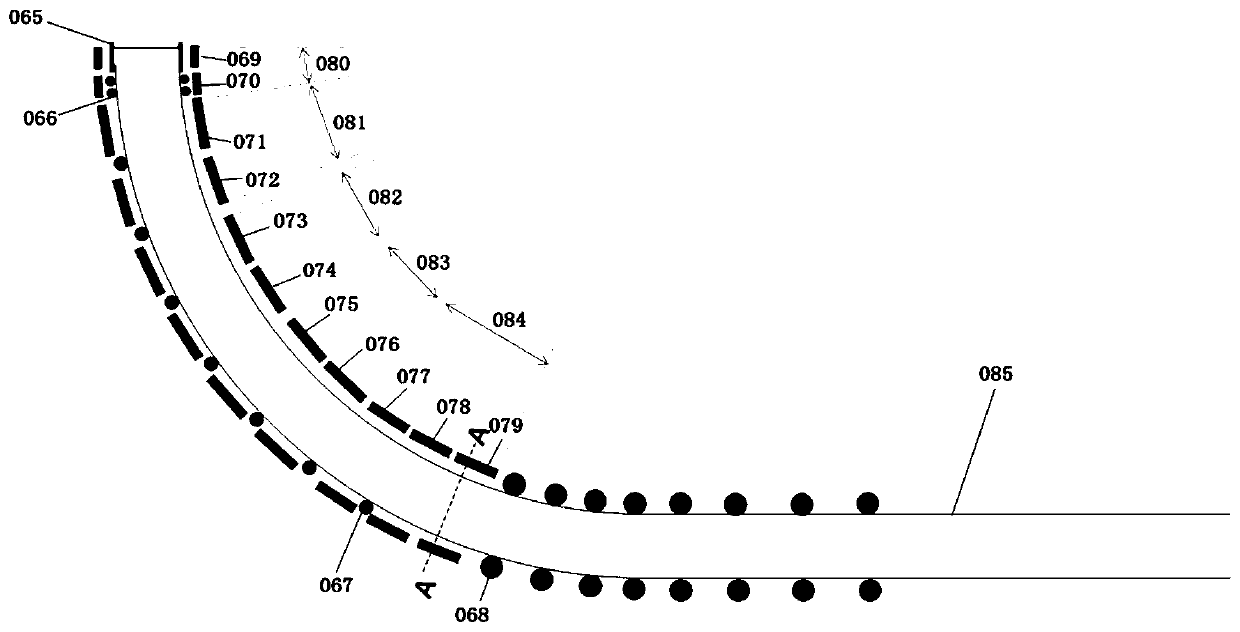

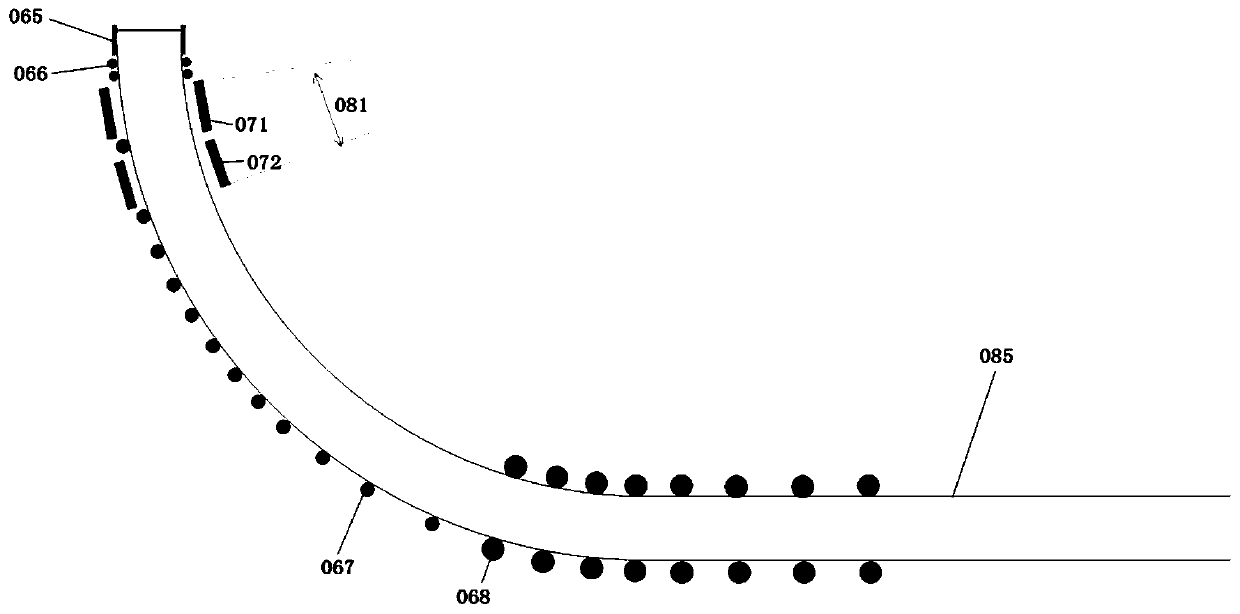

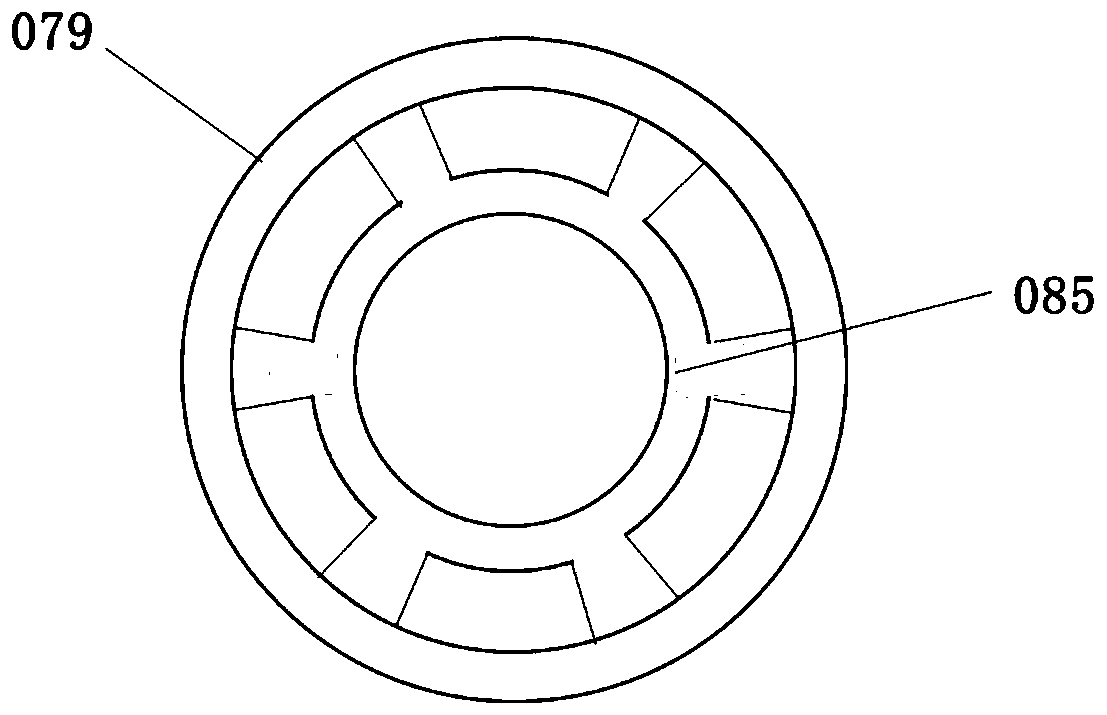

Embodiment 1

[0039] A large round billet casting machine with a diameter of 350-650mm produces 50 steel, and its multi-section linkage continuous casting magnetic stirring system controlled by time-space function is composed of a stirrer unit group, that is, there are 3 stirrer units in the secondary cooling zone ( The first stirrer unit, the second stirrer unit and the third stirrer unit) constitute the secondary cold stirring (S-EMS) unit group, about 0.8m away from the lower opening of the crystallizer, and a total length of 2.4m along the drawing direction. There is a slab cooling device. The casting speed of 350mm billet is 0.6m / min. The three stirrer units in the stirrer unit group work at the same time. The first stirrer unit is clockwise, the second stirrer unit is counterclockwise, and the third stirrer unit is clockwise. The magnetic induction at the center of the stirrer unit is about The casting speed is 300Gs; the casting speed of 650mm slab is 0.24m / min, the first two units ...

Embodiment 2

[0041] A 410mm×530mm bloom produces GCr15 and Q345 steel, and the multi-section linkage continuous casting magnetic stirring system controlled by the space-time function is composed of two stirrer unit groups. One of the agitator unit groups includes two agitator units, that is, a secondary cooling stirring (S-EMS) unit consisting of 2 agitator units (the first agitator unit and the second agitator unit) is provided in the secondary cooling zone group, about 0.9m away from the lower mouth of the crystallizer, and a total length of 1.8m along the drawing direction; another stirrer unit group includes 3 stirrer units, that is, there are 3 stirrer units (the third stirrer unit, the second stirrer unit) The solidification end-stirring (F-EMS) unit group consisting of four agitator units and the fifth agitator unit) is about 16.5m away from the lower mouth of the crystallizer, and the total length along the casting direction is 2.6m. Both unit groups are equipped with casting slabs ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com