Biodegradable beauty lifting string and preparation method thereof

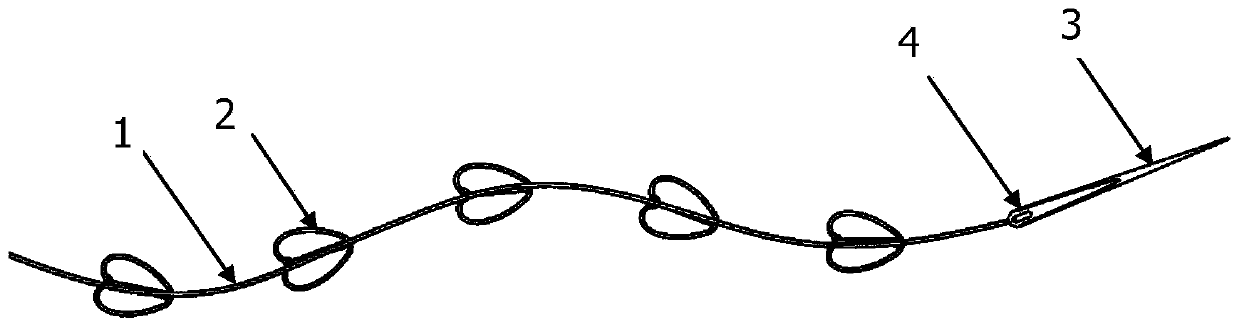

A lifting thread and biological technology, which is applied in the field of biodegradable beauty lifting thread and its preparation, can solve the problems of short degradation time, easy breaking of the lifting thread, and inability to stimulate the regeneration of skin collagen, and achieve the effect of good toughness and long time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

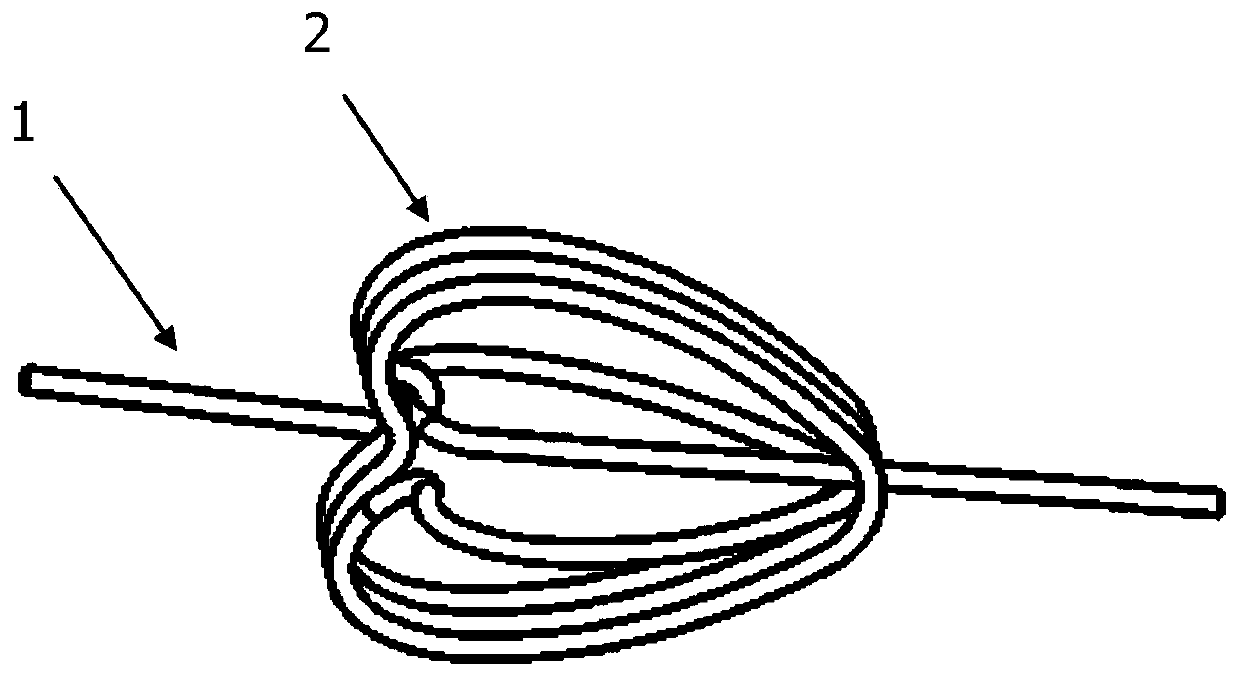

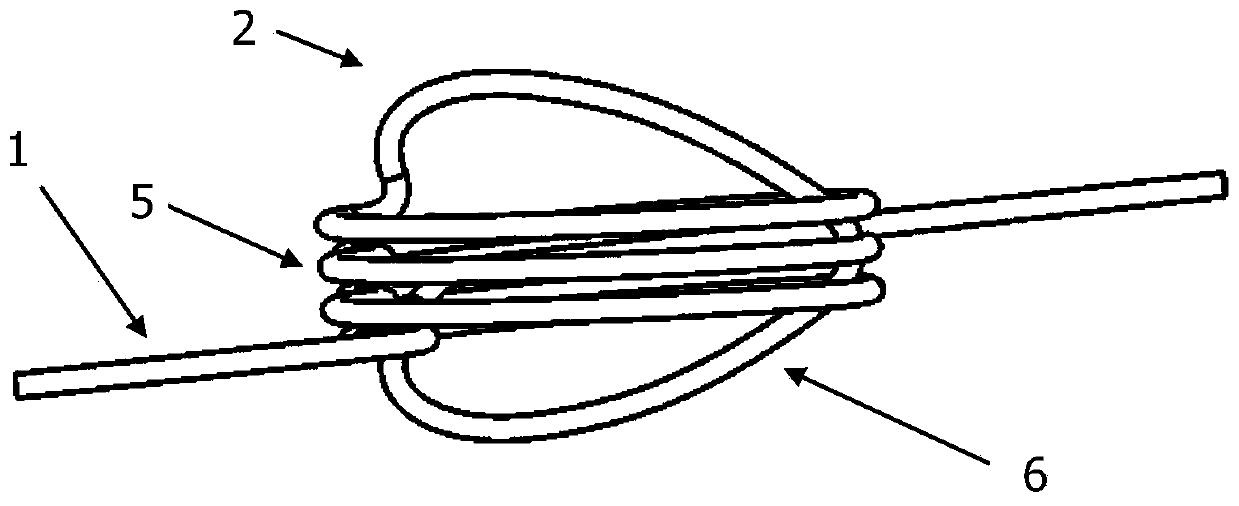

[0036] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

[0037] In this embodiment 1, both the wire body 1 and the damping cone 2 are made of zinc alloy wire material. Using ICP-AES to analyze the alloy composition of the zinc alloy wire material, the measured magnesium content is 0.5%, the content of impurity elements is not more than 0.01%, and the rest are all zinc elements. Of course, it can also be zinc-calcium alloy, zinc-magnesium-calcium alloy, zinc-lithium alloy, zinc-strontium alloy, zinc-calcium-strontium alloy, zinc-magnesium-lithium alloy, zinc-manganese alloy, zinc-magnesium-manganese alloy, zinc Any one of a magnesium-copper alloy, a zinc-neodymium alloy, a zinc-yttrium alloy, and a zinc-gadolinium alloy. In this embodiment, the zinc alloy is a zinc-magnesium alloy. After testing, the tensile strength of the material extruded bar is 320MPa, the yield strength is 280MPa, the elongatio...

Embodiment 2

[0047] In Example 2, the material is made of magnesium alloy. Specifically, it is a magnesium-zinc-calcium microalloy material. Using ICP-AES to analyze the alloy composition of the magnesium alloy material, the measured zinc content is 2%, calcium content is 0.5%, impurity element content is not more than 0.01%, and the rest are all magnesium elements . The mechanical properties of the material in the extruded rod state are tensile strength of 200MPa, yield strength of 160MPa, elongation of 22%, and reduction of area of 28%.

[0048] In Example 2, the biodegradable beauty lifting wire is made of magnesium alloy wire material, and its processing method is the same as that of the wire material in Example 1. Vacuum smelting, hot extrusion molding, spinning The compound processing method of forging, cold drawing and wire drawing, in which the raw materials are vacuum smelted with a purity higher than 99.99%. The diameter of the obtained magnesium alloy wire is 0.5mm. Accordin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com