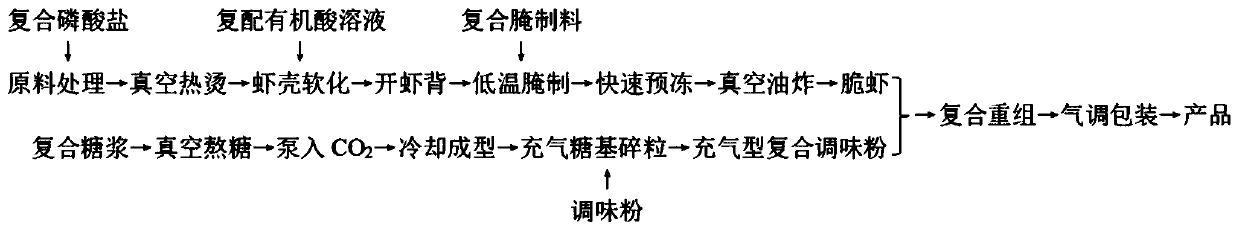

Production method of interesting ready-to-eat leisure jumping shrimps

A production method and an interesting technology, applied in the field of food processing, can solve the problems of food quality decline and nutrient loss, etc., and achieve the effects of complete organizational structure, enhanced immunity, and low astaxanthin loss rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0078] (1) Raw material processing

[0079] Select fresh prawns with uniform size and body length of about 9cm as raw materials. According to the material-to-liquid mass ratio of 1:3, the raw materials are put into an aqueous solution containing 2% salt by mass and 3.5% by mass. Compound phosphate is soaked in an aqueous solution. For 20 minutes, the soaking temperature was 10°C to spit out the dirt in the intestinal glands and stomach. Then, the shrimp were taken out, washed with clean water to remove the surface dirt, and drained. The specific composition of the composite phosphate is sodium tripolyphosphate, sodium pyrophosphate, and sodium hexametaphosphate in a mass ratio of 1:1:1.

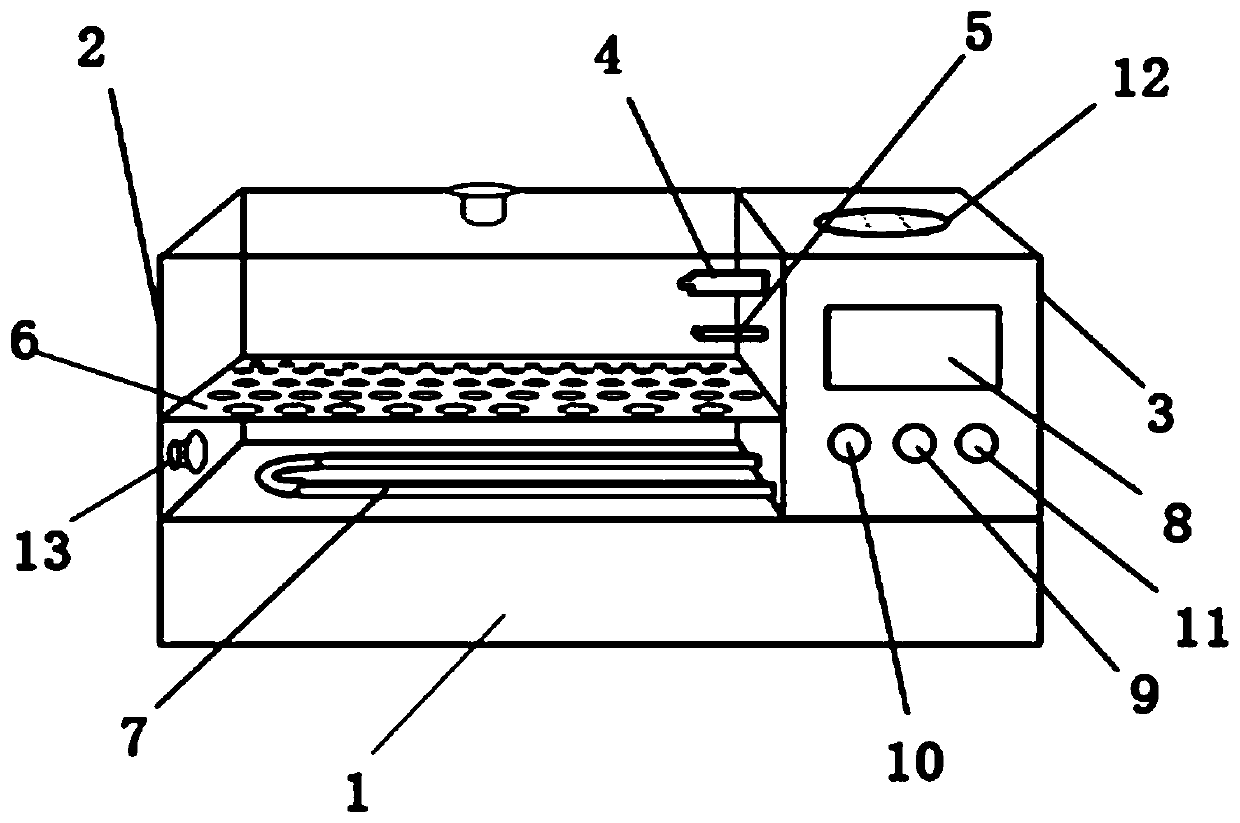

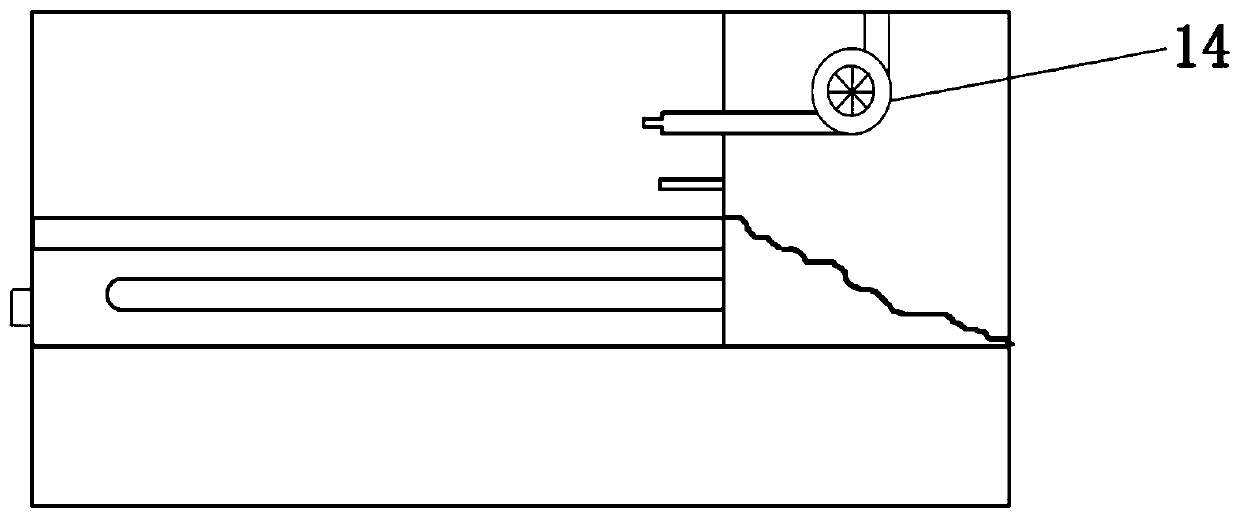

[0080] (2) Vacuum low heat blanching

[0081] The raw materials and the blanching liquid are put into a vacuum bag, and the blanching pretreatment of the raw materials is carried out in the vacuum thermal processing equipment. The degree of vacuum is -0.09MPa, and the blanching time is 5min...

Embodiment 2

[0104] (1) Raw material processing

[0105] Select fresh prawns with uniform size and body length of about 10cm as raw materials, and according to the material-liquid mass ratio of 1:2.5, put the raw materials into an aqueous solution containing 3% by mass of table salt and 3% by mass of complex phosphate. For 15 minutes, the soaking temperature was 15°C to spit out the dirt in the intestinal glands and stomach. Then, the shrimp were taken out, washed with clean water to remove the surface dirt, and drained. The specific composition of the composite phosphate is sodium tripolyphosphate, sodium pyrophosphate, and sodium hexametaphosphate in a mass ratio of 1:1:1.

[0106] (2) Vacuum low heat blanching

[0107] The raw materials and the blanching liquid are put into a vacuum bag together, and the blanching pretreatment of the raw materials is carried out in the vacuum thermal processing equipment. The degree of vacuum is -0.08MPa, and the blanching time is 3.5min. The formula...

Embodiment 3

[0130] (1) Raw material processing

[0131] Select fresh prawns with uniform size and body length of about 8cm as raw materials. According to the mass ratio of material to liquid of 1:2.7, the raw materials are put into an aqueous solution containing 2.5% salt by mass and 3.3% by mass. Compound phosphate is soaked in an aqueous solution For 18 minutes, the soaking temperature was 12°C to spit out the dirt in the intestinal glands and stomach. Then, the shrimp was taken out, washed with clean water to remove the surface dirt, and drained. The specific composition of the composite phosphate is sodium tripolyphosphate, sodium pyrophosphate, and sodium hexametaphosphate in a mass ratio of 1:1:1.

[0132] (2) Vacuum low heat blanching

[0133] The raw materials and the blanching liquid are put into a vacuum bag together, and the blanching pretreatment of the raw materials is carried out in the vacuum thermal processing equipment. The vacuum degree of the ironing equipment is -0.8...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com