Preparation method of low-temperature stabilizer

A low-temperature stability and stabilizer technology, applied in fuel additives, petroleum industry, fuels, etc., can solve the problems of poor low-temperature stability of bio-based hydrocarbon-rich fuels, achieve the effects of improving physical and chemical quality, stable properties, and expanding the scope of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

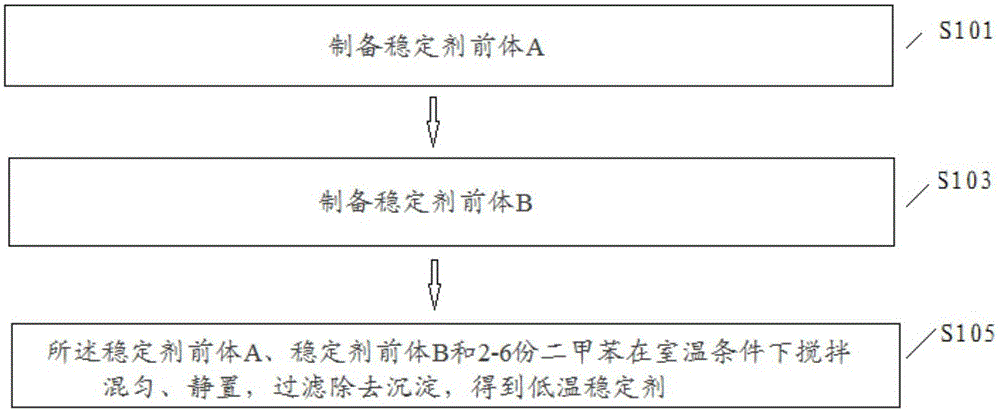

[0020] The preparation method of low temperature stabilizer

[0021] The preparation method of low-temperature stabilizer provided by the present invention: comprise the following steps: (the following components are parts by volume)

[0022] Such as figure 1 As shown in step S101, prepare stabilizer precursor A: add 3-10 parts of oleic acid, 2-5 parts of polyethylene glycol 400, and 2-5 parts of polyethylene glycol 1000 into the first reaction kettle and mix in proportion Evenly, react at 70°C-90°C, preferably 85°C, under the catalysis of a solid acid catalyst for 2h-4h, preferably 2h, cool to room temperature, filter, and then add 1-20 parts of hexadecyltrimethyl Ammonium bromide, 1-10 parts of lauryl methacrylate, 5-10 parts of polyoxyethylene lauryl ether, and 10-40 parts of triton were stirred for 1-2h to obtain stabilizer precursor A, and the composition of triton was Polyoxyethylene-8-octylphenyl ether, also known as polyethylene glycol p-isooctylphenyl ether. The pr...

Embodiment 1

[0031] Add 6 parts of oleic acid, 3 parts of polyethylene glycol 400, and 3 parts of polyethylene glycol 1000 into the first reaction kettle in proportion, react at 85°C for 2 hours under the catalysis of the solid acid catalyst p-toluenesulfonic acid, and cool to At room temperature, filter, then add 15 parts of cetyltrimethylammonium bromide, 5 parts of lauryl methacrylate, 6 parts of polyoxyethylene lauryl ether, and 35 parts of triton and stir for 1 hour to obtain the stabilizer precursor A;

[0032] Add 4 parts of isobutanol, 4 parts of isopropanol, 4 parts of octanol, and 2 parts of propylene glycol into the second reaction kettle in proportion, stir for 30 minutes at 25°C and mix well, then add 5 parts of Tween 80 and 3 parts of Diethanolamine was heated to 40°C and continued to stir for 30 minutes to mix evenly to obtain stabilizer precursor B;

[0033] The stabilizer precursor A, the stabilizer precursor B and 5 parts of xylene were mixed and stirred at room temperat...

Embodiment 2

[0036] Add 10 parts of oleic acid, 5 parts of polyethylene glycol 400, and 5 parts of polyethylene glycol 1000 in proportion to the first reaction kettle, at 80 ° C and in the solid acid catalyst Fe 2 (SO 4 ) 3React under the catalysis of 4h, cool to room temperature, filter, then add 20 parts of cetyltrimethylammonium bromide, 1 part of lauryl methacrylate, 10 parts of lauryl polyoxyethylene ether, 10 parts of triton Stir for 2h to obtain stabilizer precursor A;

[0037] Add 5 parts of isobutanol, 5 parts of isopropanol, 6 parts of octanol, and 6 parts of propylene glycol into the second reaction kettle in proportion, stir for 30 minutes at 25°C and mix well, then add 6 parts of Tween 80, 5 parts of Diethanolamine was heated to 20°C and continued to stir for 30 minutes to mix evenly to obtain stabilizer precursor B;

[0038] The stabilizer precursor A, the stabilizer precursor B and 6 parts of xylene were mixed and stirred at room temperature for 30 minutes, left to stand ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| dew point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com