Extraction method of cashew kernel oil

An extraction method and technology of cashew nuts, which are applied in the direction of fat oil/fat production and fat generation, can solve the problems that are not conducive to the utilization value of cashew nut oil, the extraction rate of cashew nut oil is low, and the price of cashew nut kernel is high, so as to improve the physical and chemical quality, The effect of increasing the dissolution rate and lowering the demulsification temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

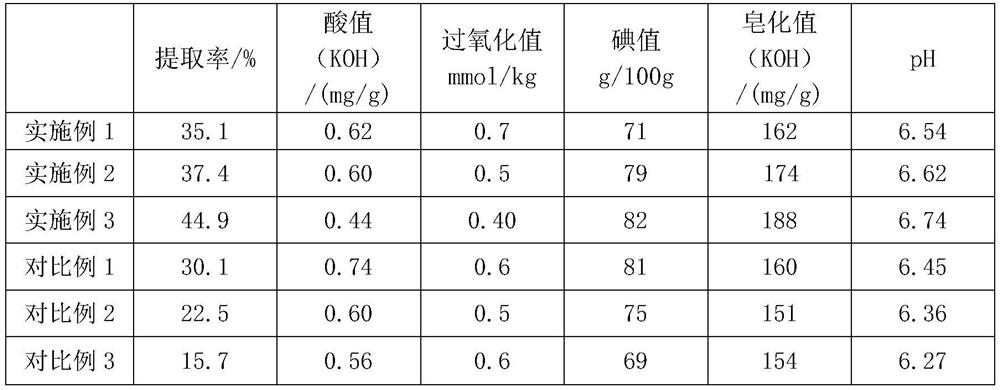

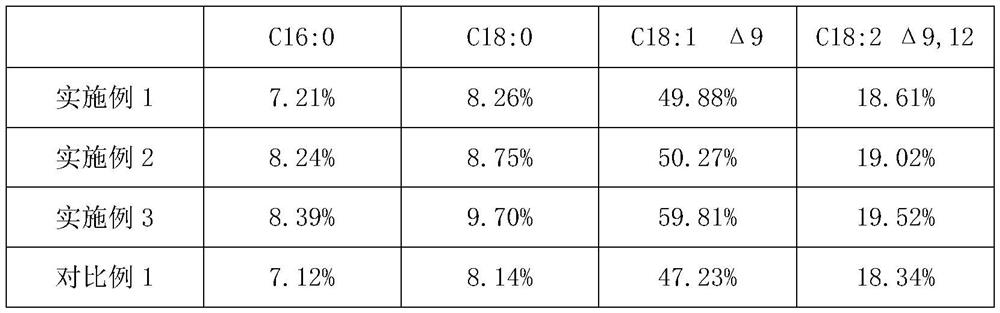

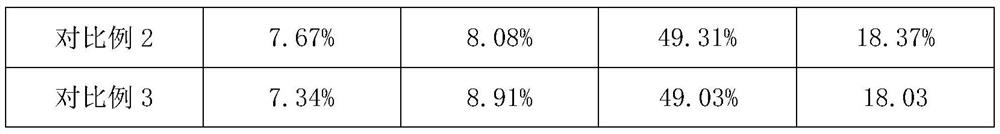

Examples

Embodiment 1

[0026] A method for extracting cashew kernel oil, comprising the steps of:

[0027] (1) Pulverization: pulverize the dried nuts to 40 mesh;

[0028] (2) Refining: Mix the nuts crushed in step (1) with water according to a ratio of 1:2 to liquid, and place them in a colloid mill for refining, with a gap of 10 μm between the colloid mills.

[0029] (3) Homogenization: put the slurry after step (2) refining into a homogenizer for homogenization, and the homogenization pressure is 60Mpa;

[0030] (4) Enzyme inactivation: heat up the homogenized slurry in step (3) to 75°C within 10s and maintain it for 30s, then cool down to 55°C within 180s to achieve enzyme inactivation;

[0031] (5) Stirring and emulsification: put the slurry after step (4) inactivating the enzyme in a stirrer to stir the slurry quickly, the stirring temperature is 55°C, the stirring speed is 50rpm, and the stirring time is 0.5h.

[0032] (6) Centrifugal impurity removal: the slurry obtained in step (5) is pla...

Embodiment 2

[0036] A method for extracting cashew kernel oil, comprising the steps of:

[0037] (1) Pulverization: pulverize the dried nuts to 80 mesh;

[0038] (2) Refining: mix the crushed nuts and water in step (1) according to a ratio of 1:10 to liquid, place in a colloid mill for refining, and the gap between the colloid mills is 40 μm;

[0039] (3) homogeneous: put the slurry after step (2) refining into a homogenizer for homogenization, and the homogenization pressure is 150Mpa;

[0040] (4) Enzyme inactivation: heat up the homogenized slurry in step (3) to 110°C within 60s for 10s, then cool down to 65°C within 30s to achieve enzyme inactivation;

[0041] (5) Stirring and emulsification: place the slurry after step (4) inactivating the enzyme in a stirrer to quickly stir the slurry, the stirring temperature is 65°C, the stirring speed is 120rpm, and the stirring time is 3h;

[0042] (6) Centrifugal impurity removal: place the slurry obtained in step (5) in a centrifuge for 1 min...

Embodiment 3

[0046] A method for extracting cashew kernel oil, comprising the steps of:

[0047] (1) Pulverization: pulverize the dried nuts to 60 mesh;

[0048] (2) Refining: mix the crushed nuts and water in step (1) according to a material-to-liquid ratio of 1:6, place them in a colloid mill for refining, and the gap between the colloid mills is 20 μm;

[0049] (3) Homogenization: put the slurry after step (2) refining into a homogenizer for homogenization, with a homogenization pressure of 100Mpa;

[0050] (4) Enzyme inactivation: Warm up the homogenized slurry in step (3) to 95°C within 30s and maintain it for 100s, then cool down to 60°C within 100s to achieve enzyme inactivation;

[0051] (5) Stirring and emulsification: place the slurry after step (4) inactivating the enzyme in a stirrer to quickly stir the slurry, the stirring temperature is 60°C, 80rpm, and stir for 1.0h;

[0052] (6) Centrifugal impurity removal: the slurry obtained in step (5) is placed in a centrifuge for 5 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com