Hard alloy coating layer capable of being totally dissolved in water medium and preparation method and application thereof

A technology of complete dissolution of cemented carbide, applied in metal material coating process, coating, earthwork drilling and mining, etc., can solve the problems of affecting the use effect of tools, not easy to flow back, insoluble, etc., so as to save the grinding and milling process , Facilitate flowback and improve construction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

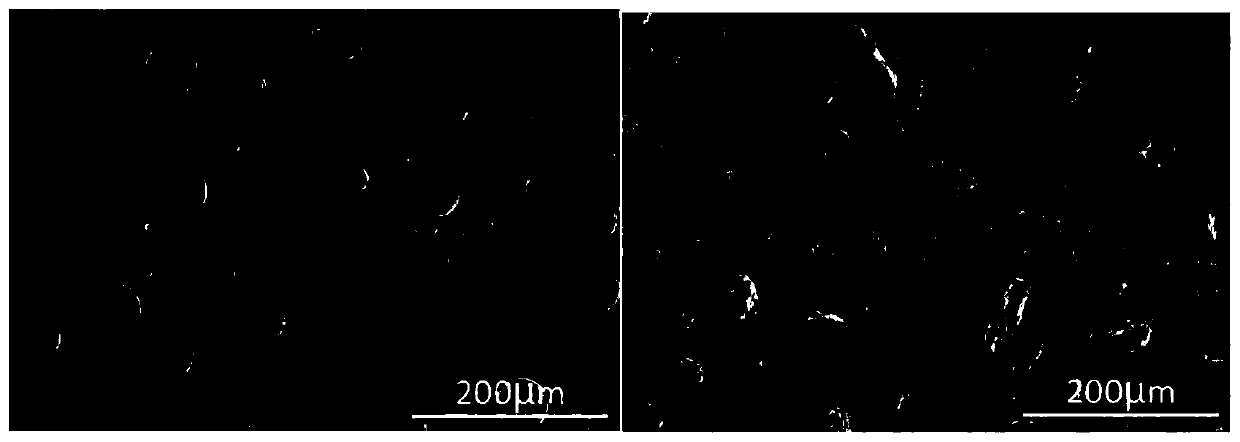

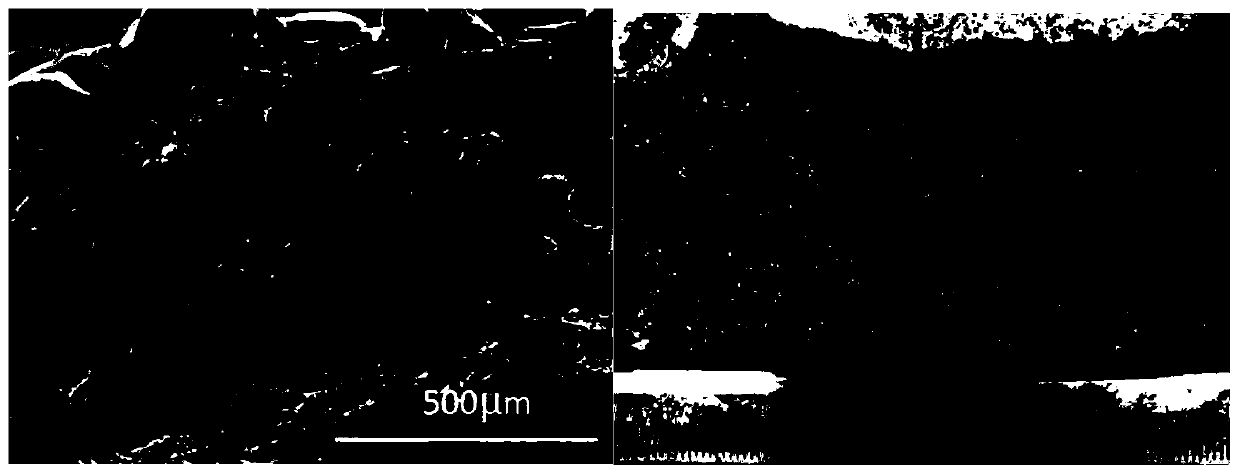

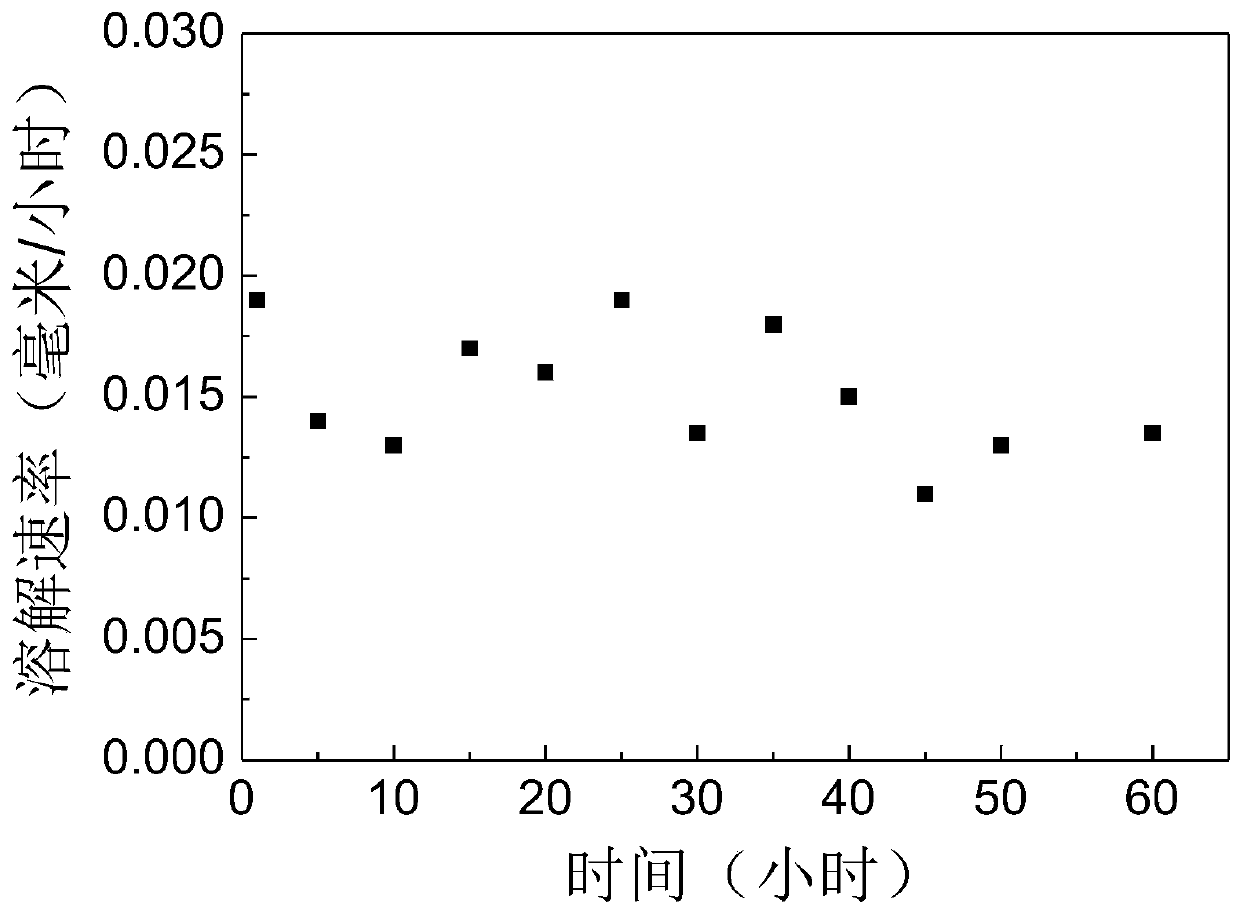

Image

Examples

Embodiment 1

[0037] This embodiment provides a cemented carbide coating that is completely soluble in an aqueous medium and is composed of a soluble aluminum alloy and a nickel-based alloy, wherein the volume ratio of the soluble aluminum alloy and the nickel-based alloy is 1:9. The soluble aluminum alloy components and the mass percentage of each component are: 3% Mg, 1% Cu, 1.3% Ga, 0.2% In, and the balance is Al. The soluble aluminum alloy is at 95°C and the concentration is 3wt.%. The dissolution rate in KCl solution is 15mg / cm 2 hr; the nickel-based alloy is Ni60, and the particle size is 250 mesh.

[0038] Concrete preparation steps are as follows:

[0039] (1) Process the above-mentioned soluble aluminum alloy block into small chips, and use a ball mill (the volume ratio of balls and soluble aluminum alloy chips is 1:1) to grind the chips into small chips at 300 rpm / min for 6 hours. Powder, the size of which is screened out is 200 mesh powder to obtain soluble aluminum alloy powde...

Embodiment 2

[0047] This embodiment provides a cemented carbide coating that is completely soluble in an aqueous medium and is composed of a soluble magnesium alloy and an iron-based alloy, wherein the volume ratio of the soluble magnesium alloy and the iron-based alloy is 1:11.5. The soluble magnesium alloy components and the mass percentage content of each component are: 8% Al, 1.5% Zn, 0.5% Ni, and the balance is Mg. The soluble magnesium alloy is dissolved in a 3wt.% KCl solution at 95°C The rate is 25mg / cm 2 hr; iron-based alloy is Fe60, particle size 200 mesh.

[0048] Concrete preparation steps are as follows:

[0049] (1) Process the above-mentioned soluble magnesium alloy block into small chips, and use a ball mill (the volume ratio of balls and soluble magnesium alloy chips to be 1:2) to grind the chips into small chips at a speed of 300 rpm for 6 hours. Powder, the size of which is screened out is 200 mesh powder to obtain soluble magnesium alloy powder;

[0050] (2) Mix the ...

Embodiment 3

[0054] This embodiment provides a cemented carbide coating that is completely soluble in an aqueous medium and is composed of a soluble aluminum alloy and a nickel-based alloy, wherein the volume ratio of the soluble aluminum alloy and the nickel-based alloy is 1:6. The soluble aluminum alloy components and the mass percentage of each component are: 3% Mg, 1% Cu, 1.3% Ga, 0.2% In, and the balance is Al. The soluble aluminum alloy is at 95°C and the concentration is 3wt.%. The dissolution rate in KCl solution is 25mg / cm 2 hr; nickel-based alloy is Ni60, particle size 300 mesh.

[0055] Concrete preparation steps are as follows:

[0056] (1) Process the above-mentioned soluble aluminum alloy block into small chips, and use a ball mill (the volume ratio of balls and soluble aluminum alloy chips is 1:1.5) to grind the chips into small chips at 300 rpm / min for 6 hours. Powder, the size of which is screened out is 200 mesh powder to obtain soluble aluminum alloy powder;

[0057] ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com