Cast wear-resistant alloy liner

A wear-resistant alloy and liner technology, which is applied in the field of wear-resistant liners, can solve the problems of easy fracture and low service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

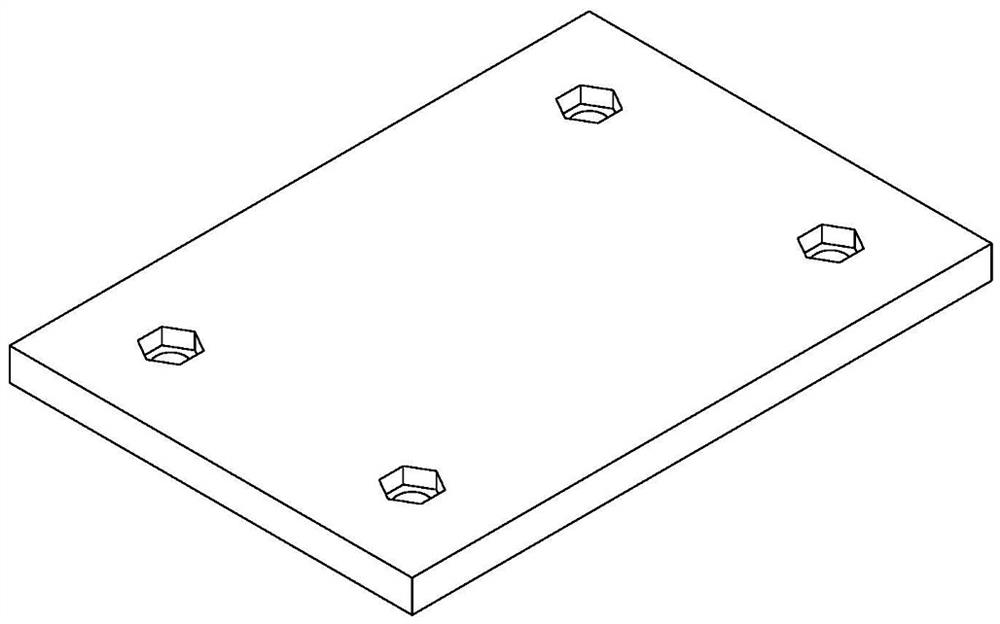

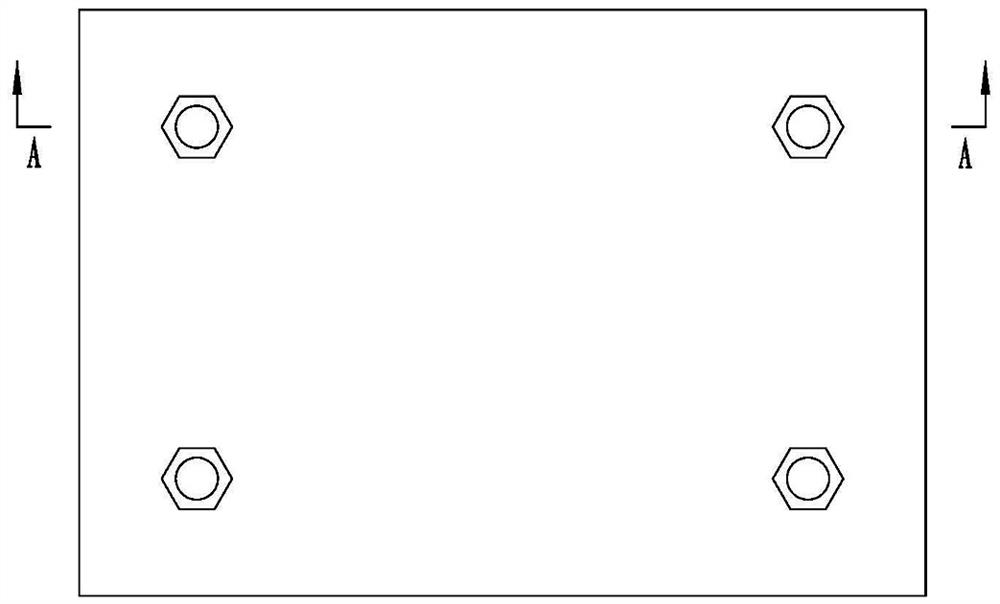

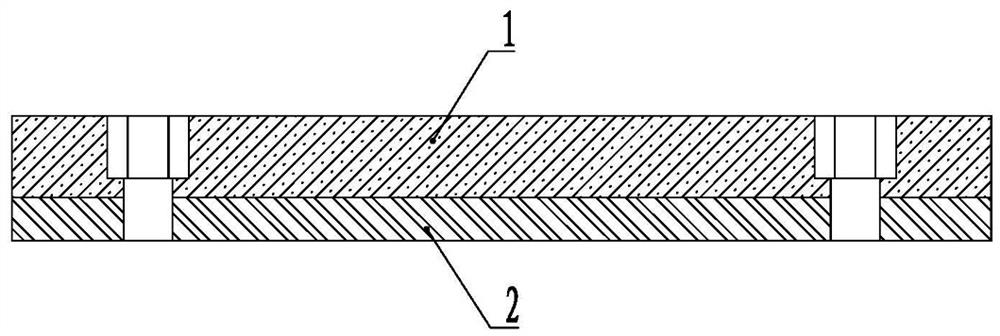

[0021] like Figure 1 to Figure 3 The fused cast wear-resistant alloy liner shown includes the liner body. The working surface of the liner body is composed of an upper layer and a lower layer. The upper layer is a high-chromium anti-wear white cast iron layer 1, and the lower layer is a high-manganese wear-resistant steel layer 2 ;

[0022] High chromium wear-resistant white cast iron layer 1 is made of the following raw materials in weight percentage: 1.0% carbon, 0.5% silicon, 0.3% manganese, 23.0% chromium, 1.0% molybdenum, 1.5% nickel, 1.0% copper, 0.03% sulfur, Silicon 0.03%, tungsten 0.03%, the balance is pig iron;

[0023] The high manganese wear-resistant steel layer 2 is made of the following raw materials in weight percentage: carbon 0.38%, silicon 0.5%, manganese 11.0%, chromium 0.03%, molybdenum 1.4%, nickel 1.0%, copper 0.01%, sulfur 0.02%, silicon 0.01% %, 0.02% tungsten, and the balance is pig iron.

[0024] The fused-cast wear-resistant alloy liner in this ...

Embodiment 2

[0029] like Figure 1 to Figure 3 The fused cast wear-resistant alloy liner shown includes the liner body. The working surface of the liner body is composed of an upper layer and a lower layer. The upper layer is a high-chromium anti-wear white cast iron layer 1, and the lower layer is a high-manganese wear-resistant steel layer 2 ;

[0030] The high-chromium anti-wear white cast iron layer 1 is made of the following raw materials in weight percentage: 1.3% carbon, 0.8% silicon, 0.7% manganese, 26.0% chromium, 1.5% molybdenum, 2.0% nickel, 1.5% copper, 0.04% sulfur, Silicon 0.06%, tungsten 0.06%, the balance is pig iron;

[0031] The high manganese wear-resistant steel layer 2 is made of the following raw materials in weight percentage: carbon 0.52%, silicon 0.8%, manganese 12.0%, chromium 0.06%, molybdenum 1.9%, nickel 2.5%, copper 0.02%, sulfur 0.03%, silicon 0.03% %, 0.03% tungsten, and the balance is pig iron.

[0032] The fused-cast wear-resistant alloy liner in this e...

Embodiment 3

[0037] like Figure 1 to Figure 3 The fused cast wear-resistant alloy liner shown includes the liner body. The working surface of the liner body is composed of an upper layer and a lower layer. The upper layer is a high-chromium anti-wear white cast iron layer 1, and the lower layer is a high-manganese wear-resistant steel layer 2 ;

[0038] The high-chromium anti-wear white cast iron layer 1 is made of the following raw materials in weight percentage: 1.6% carbon, 1.0% silicon, 1.0% manganese, 30.0% chromium, 2.0% molybdenum, 2.5% nickel, 2.0% copper, 0.06% sulfur, Silicon 0.10%, tungsten 0.1%, the balance is pig iron;

[0039] The high manganese wear-resistant steel layer 2 is made of the following raw materials in weight percentage: 0.65% carbon, 1.2% silicon, 14% manganese, 0.08% chromium, 2.4% molybdenum, 4.0% nickel, 0.03% copper, 0.04% sulfur, 0.04% silicon %, 0.05% tungsten, and the balance is pig iron.

[0040] The fused-cast wear-resistant alloy liner in this embo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com