Nuclear power station plant water pump shaft seal water supply system

A supply system, water pump shaft technology, applied in the water supply pipeline system, nuclear power generation, pumping station, etc., can solve the problems that affect the life of the shaft seal, shaft seal wear, etc., achieve fast response, eliminate human errors, and ensure independence Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

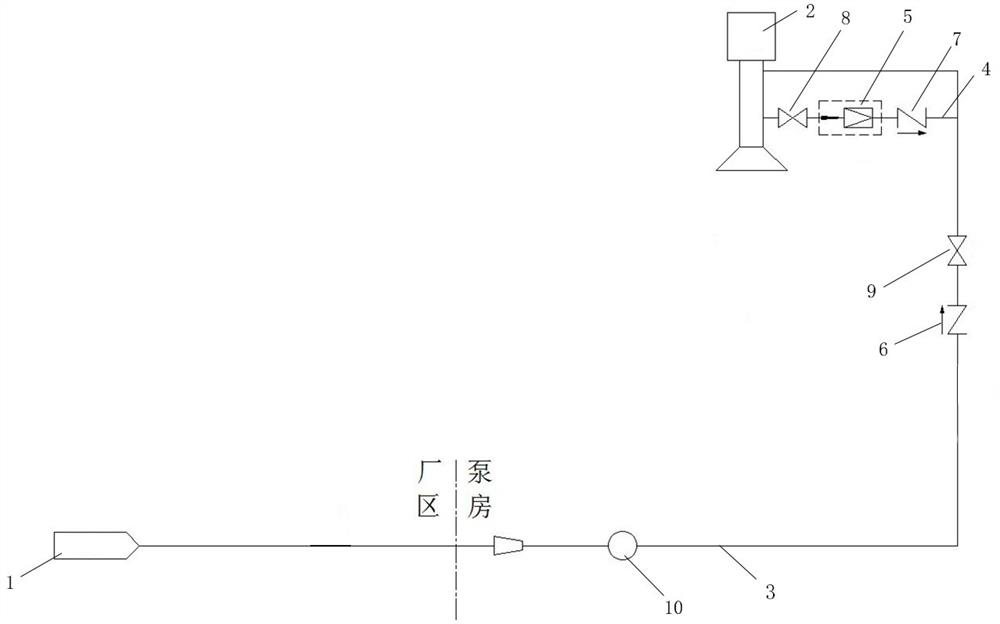

[0028] like figure 1 As shown, a nuclear power plant plant water pump shaft seal water supply system includes a production water distribution system 1, a water supply pipeline 3 connecting the production water distribution system 1 and the plant water pump 2, and is located at the water outlet of the plant water pump 2 and the The emergency water supply pipeline 4 between the water supply pipelines 3, the pressure reducing valve 5 arranged on the emergency water supply pipeline 4, the valve located upstream of the emergency water supply pipeline 4 on the described water supply pipeline 3 The first check valve 6, the water pressure in the emergency water supply pipeline 4 at the end of the pressure reducing valve 5 close to the water supply pipeline 3 is lower than the water pressure in the water supply pipeline 3, and the water supply pipeline The water pressure in 3 is lower than the water pressure at the water outlet of the plant water pump 2. Of course, the decompression v...

Embodiment 2

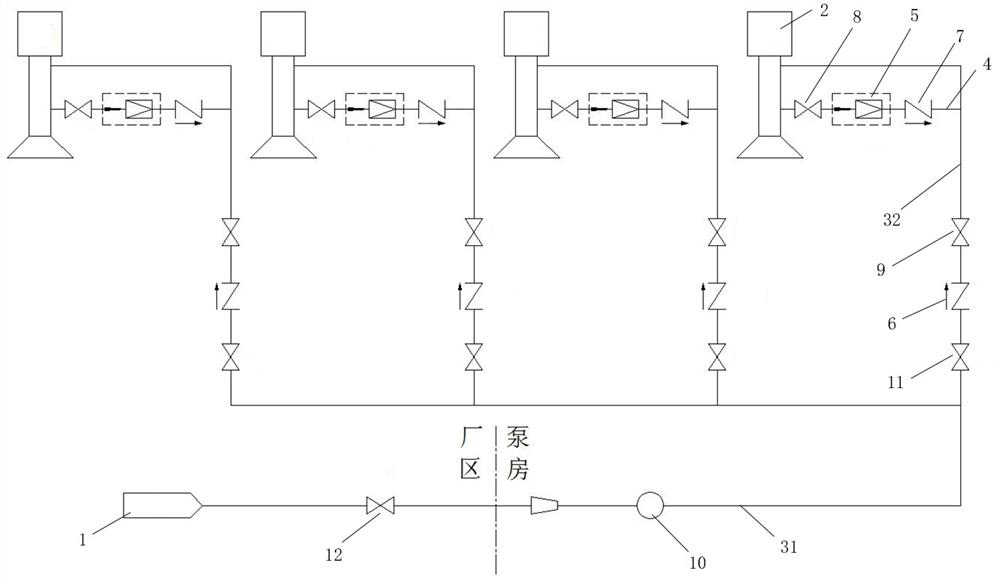

[0033] like figure 2As shown, different from Embodiment 1, the plant water pump 2 has multiple, and the water supply pipeline 3 includes a main pipe 31 connected to the production water distribution system 1, and a pipe connected to each plant water pump 2 respectively. A branch pipe 32 , the emergency water supply pipeline 4 is connected to the branch pipe 32 , and the first check valve 6 is arranged on the branch pipe 32 . The end of the branch pipe 32 connected to the main pipe 31 is provided with a third isolation valve 11, which is mainly used to control the opening and closing of the water supply of different branch pipes, so as to improve the controllability and facilitate the detection of the water supply conditions of different branch pipes. The main pipe 31 is provided with a fourth isolation valve 12 for controlling the water supply of the main pipe. The main pipe 31 is provided with a flow meter 10, and when testing the water supply of a single branch pipe, it is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com