Electromagnetic shielding cable material and preparation method thereof

An electromagnetic shielding and cable material technology, applied in the field of functional materials, can solve the problems of the influence of communication cable signal transmission, poor shielding effect of metal materials, low frequency, etc., and achieve the effects of improving market competitiveness, convenient construction and reducing production costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

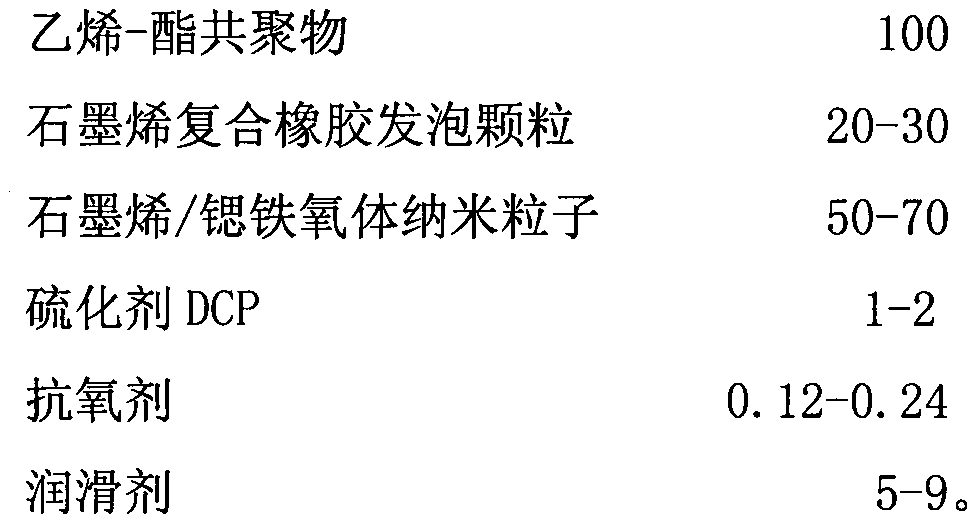

[0029] An electromagnetic shielding cable material consists of the following components in parts by mass:

[0030]

[0031] The antioxidant is β-(3,5-di-tert-butyl-4-hydroxyphenyl) n-octadecyl propionate.

[0032] Described lubricant is calcium stearate.

[0033] A preparation method of electromagnetic shielding cable material, comprising the following steps:

[0034] (1) Preheat the internal mixer to 82°C, add 30 parts by mass of natural rubber, 8 parts by mass of cis-butadiene rubber, and 25 parts by mass of styrene-butadiene rubber and masticate for 10 minutes, then add 0.9 parts by mass of zinc stearate, 1.5 parts by mass of Parts of microcrystalline wax, 0.4 parts by mass of anti-aging agent RD, 0.6 parts by mass of foaming agent and 0.7 parts by mass of silane coupling agent, mixed for 5 minutes at a speed of 45r / min, added 0.3 parts by mass of graphene, heated to 130 °C, and mixed 8min, finally add 0.5 parts by mass of vulcanizing agent PDM and 0.2 parts by mass of...

Embodiment 2

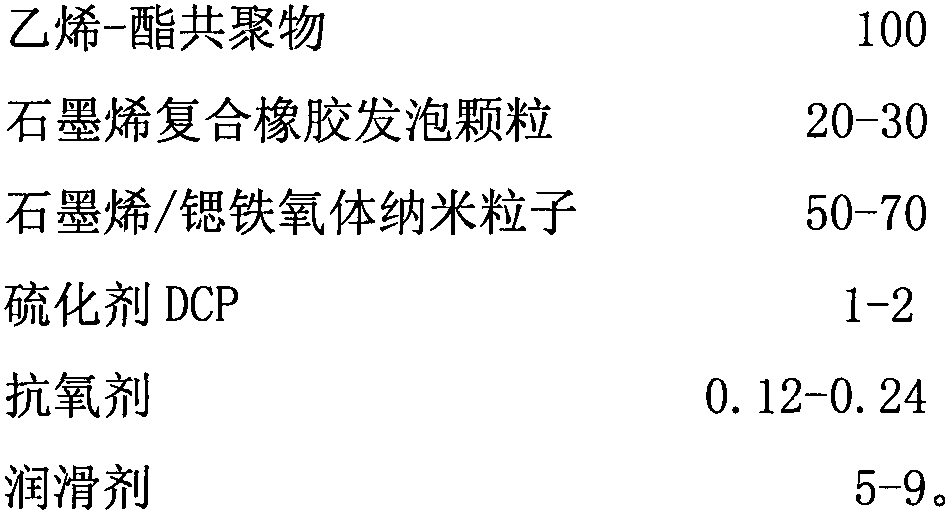

[0041] An electromagnetic shielding cable material consists of the following components in parts by mass:

[0042]

[0043] The antioxidant is tetrakis[β-(3,5-di-tert-butyl-4-hydroxyphenyl)propionic acid]pentaerythritol ester.

[0044] Described lubricant is a kind of in calcium stearate or zinc stearate.

[0045] A preparation method of electromagnetic shielding cable material, comprising the following steps:

[0046] (1) Preheat the internal mixer to 78°C, add 25 parts by mass of natural rubber, 6 parts by mass of butadiene rubber, and 20 parts by mass of styrene-butadiene rubber for mastication for 8 minutes, then add 0.6 parts by mass of zinc stearate, 1 mass part of Parts of microcrystalline wax, 0.3 parts by mass of anti-aging agent RD, 0.5 parts by mass of foaming agent and 0.6 parts by mass of silane coupling agent, kneaded at a speed of 40r / min for 4min, added 0.2 parts by mass of graphene, heated to 120°C, and kneaded 6min, finally add 0.4 parts by mass of vulca...

Embodiment 3

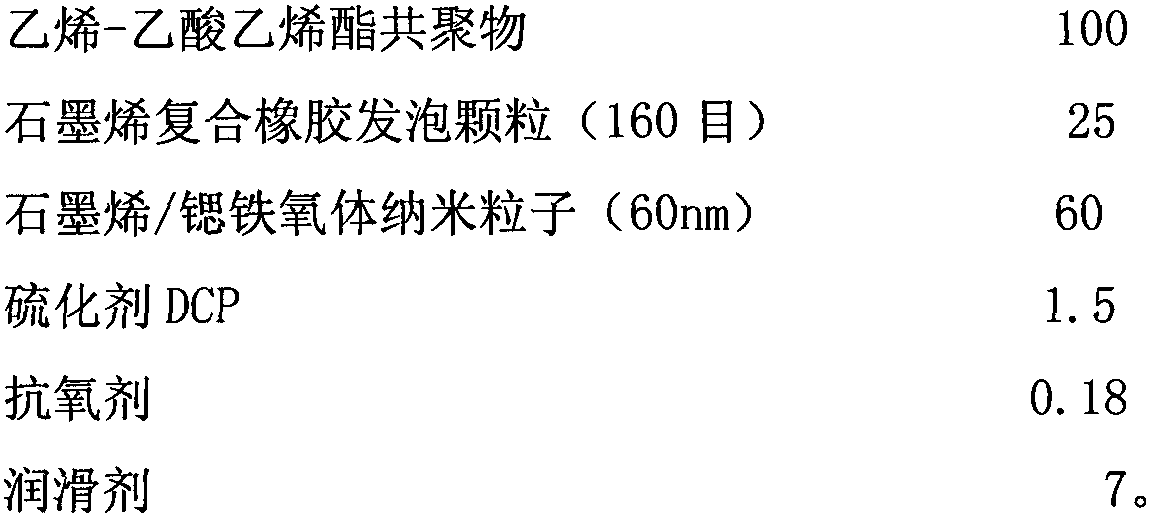

[0053] An electromagnetic shielding cable material consists of the following components in parts by mass:

[0054]

[0055] The antioxidant is tetrakis[β-(3,5-di-tert-butyl-4-hydroxyphenyl)propionic acid]pentaerythritol ester.

[0056] Described lubricant is zinc stearate.

[0057] A preparation method of electromagnetic shielding cable material, comprising the following steps:

[0058] (1) Preheat the internal mixer to 86°C, add 35 parts by mass of natural rubber, 10 parts by mass of butadiene rubber, and 30 parts by mass of styrene-butadiene rubber for 12 minutes, then add 1.2 parts by mass of zinc stearate, 2 parts by mass of Parts of microcrystalline wax, 0.5 parts by mass of anti-aging agent RD, 0.7 parts by mass of foaming agent and 0.8 parts by mass of silane coupling agent, mixed for 6 minutes at a speed of 50 r / min, added 0.4 parts by mass of graphene, heated to 140 ° C, and mixed 10min, finally add 0.6 parts by mass of vulcanizing agent PDM and 0.3 parts by mass...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com