A kind of water-soluble hyperbranched polymer heavy oil viscosity reducer and preparation method thereof

A hyperbranched polymer, water-soluble technology, used in chemical instruments and methods, drilling compositions, etc., can solve the problems of complicated synthesis or compounding steps, poor temperature and salt resistance, and small reservoir conditions. , to achieve the effects of low cost, strong temperature and salt resistance, and simple synthesis steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

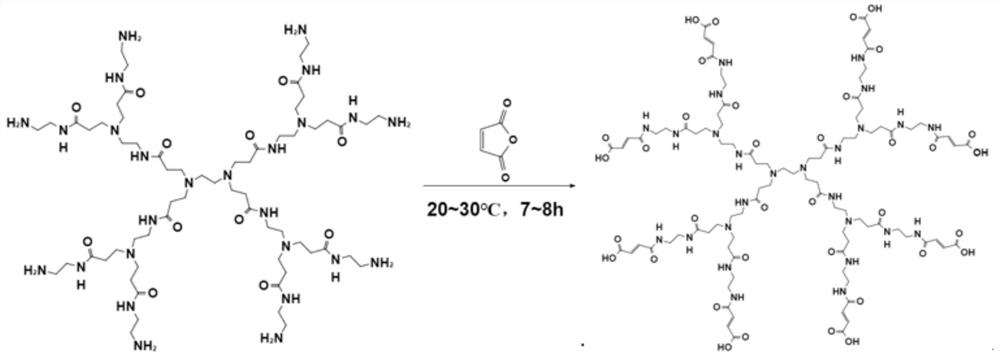

[0051] (a) Functional modification of backbone monomers

[0052] The 2.0 generation or 3.0 generation backbone monomer and maleic anhydride are sequentially dissolved in 2 to 3 times the mass ratio of N,N-dimethylformamide solvent in a molar ratio of 1:8 or 1:16; Place the system in an ice-water bath (below 10°C), and pass nitrogen gas for 40 minutes at the same time, and dissolve completely under stirring conditions; react for 6h to 7h at room temperature and avoid light; Precipitate milky white, light yellow powdery substance, which is relatively pure functionalized skeleton monomer.

[0053] Taking the modified 2.0 generation as an example, the preparation flow chart of the functionalized 2.0 skeleton monomer is as follows figure 1 shown.

[0054] Modified 2.0 generation polyamide-amine, its molecular structural formula is as shown in (1):

[0055]

[0056] Modified 3.0 generation polyamide-amine, its molecular structural formula is as shown in (2):

[0057]

[00...

Embodiment 2

[0068] The synthesis of water-soluble hyperbranched heavy oil viscosity reducer, its preferred scheme is as follows:

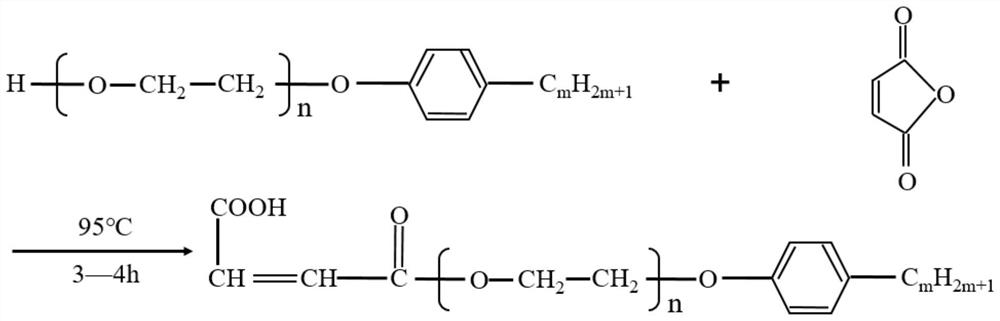

[0069] First, put a certain amount of deionized water in the reaction vessel, and mix 0.4% of functionalized backbone monomer 2.0 generation polyamidoamine, 14.5% of acrylamide, and 40.1% of modified The octylphenol polyoxyethylene ether maleic acid monoester (shown in formula 3, wherein n is 10, m is 8) and 45% sodium olefin sulfonate monomer (n 2 =14~16, Chengdu Kelong Chemical Reagent Factory, AOS liquid) mix and stir evenly, be mixed with the solution (mass fraction meter) that monomer concentration is 25%;

[0070] Secondly, by adding sodium hydroxide to adjust the pH value of the solution to 6.5, then under 45°C water bath heating and a stirring speed of 250r / min, the inert gas nitrogen was used for protection for 40min; then ammonium persulfate solution was slowly added dropwise, the over Ammonium persulfate in the ammonium sulfate solution is 0.01% re...

Embodiment 3

[0072] The synthesis of water-soluble hyperbranched heavy oil viscosity reducer, its preferred scheme is as follows:

[0073] First, put a certain amount of deionized water into the reaction vessel, and mix 0.1% of functionalized backbone monomer 3.0 generation polyamidoamine, 13.8% of acrylamide, 38.5% of modified Nonylphenol polyoxyethylene ether maleic acid monoester (shown in formula 3, n is 10, m is 9) and 47.6% sodium olefin sulfonate monomer, mixed and stirred evenly, and prepared into a monomer concentration of 25%. Solution (mass fraction meter);

[0074] Secondly, the pH value of the solution was adjusted to 6.7 by adding sodium carbonate, and then under 45°C water bath heating and a stirring rate of 250r / min, the inert gas nitrogen was passed for protection for 40min; then the ammonium persulfate solution was slowly added dropwise, and the persulfate Ammonium persulfate in the ammonium solution is 0.018% relative to the total mass of the monomers. After continuing ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| shear viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com