Crawler brake oil pressure flow meter oiling equipment for construction machinery

A technology of construction machinery and brake oil pressure, which is applied in special distribution devices, packaging, distribution devices, etc., can solve the problems of high proportion of petroleum equipment usage, oil waste, spilling, etc., and achieve convenient and fast refueling process, structure Rigorous design to enhance the effect of volatilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be further described below in conjunction with the drawings.

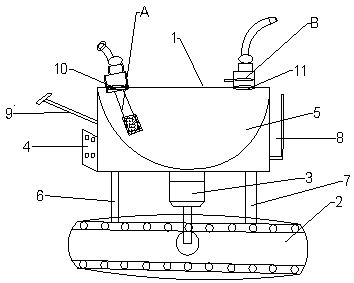

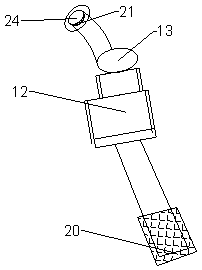

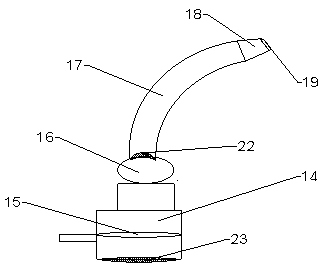

[0013] Such as Figure 1 to Figure 3 As shown, the present invention is a crawler brake oil pressure flow meter refueling equipment for construction machinery, including an equipment body shell 1, a crawler device 2, an electric motor 3, and a control board device 4. The device body shell 1 is provided with a circle The arc container 5, the interlayer between the bottom of the arc container 5 and the inside of the equipment body shell 1 is set as a vacuum hollow, the bottom of the equipment body shell 1 is fixedly connected to one side of the crawler device 2 by a pillar rod I6, and the bottom of the equipment body shell 1 is fixed by a pillar rod II7 Connected to the other side of the crawler device 2, the motor 3 is arranged between the pillar rod I6 and the pillar rod II7, the top of the motor 3 is fixedly connected to the bottom of the equipment body shell 1, and the bottom shaft ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com