A composite material including anti-delamination wool fabric and its preparation method

A composite material, anti-delamination technology, applied in the direction of layered products, chemical instruments and methods, lamination, etc., can solve the problems of low standardization of production process, high production cost, manual participation, etc., to improve the performance between layers , The effect of improved interlayer peel strength and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0024] Embodiments of the present application relate to a method for preparing a composite material comprising an anti-delamination wool fabric, comprising the following steps:

[0025] Step 1. Hook part of the fibers on the surface of the fabric with a crochet roller to form a wool fabric;

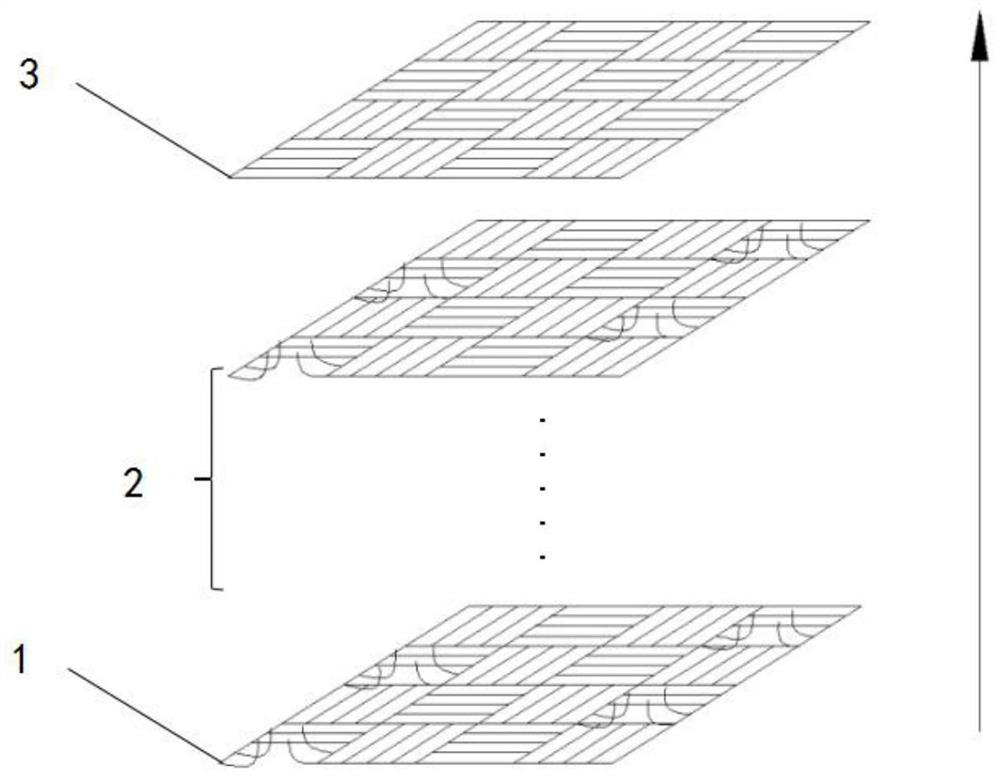

[0026] Step 2. Lay ordinary fabrics, single-sided wool fabrics or double-sided wool fabrics, apply pressure evenly, and combine the fabrics to form an anti-delamination laminated fabric, wherein the order of laying is that one ordinary surface is in contact with one wool surface Stacked;

[0027] Step 3, cutting the layered fabric described in step 2 as required, impregnating it with a polymer resin as a matrix in a mold, and then closing the mold and forming it by hot pressing to obtain the composite material comprising the delamination-resistant wool fabric;

[0028] Through the relative movement of the crochet roller on the surface of the fabric, the crochet hooks the transverse fiber...

Embodiment 1

[0039] A method for preparing a composite material comprising an anti-delamination wool fabric, comprising the following steps:

[0040] Step 1. Use the crochet roller to move relative to the surface of the glass fiber plain weave fabric, so that the crochet hooks the transverse fibers perpendicular to the direction of movement when the crochet needles are in contact with the fabric. Matte fiberglass fabric;

[0041] Step 2. Layer sequence design: Lay from the lower layer to the upper layer. The first layer is ordinary glass fiber plain weave fabric, which is the lower surface layer. The second layer is double-sided matte glass fiber fabric, which is the middle layer. The third layer It is an ordinary glass fiber twill fabric, which is the upper surface layer. There are three layers in total. A certain vertical pressure is evenly applied on the upper surface fabric to make the three layers of fabric tightly bonded, and each layer of fabric is laid according to the designed ang...

Embodiment 2

[0044] A method for preparing a composite material comprising an anti-delamination wool fabric, comprising the following steps:

[0045] Step 1. Use the crochet roller to move relative to the surface of the carbon fiber twill fabric, so that when the crochet needles are in contact with the fabric, they will hook the transverse fibers perpendicular to the direction of movement. Double-sided matte carbon fiber fabric;

[0046] Step 2. Layer sequence design: Lay from the lower layer to the upper layer. The first layer is ordinary carbon fiber twill fabric, which is the lower surface layer. The second layer is double-sided wool-faced carbon fiber fabric, which is the lower surface layer. The third to The fourth layer is a single-sided wool-faced carbon fiber twill fabric, with the wool side up, which is the middle layer, and the fifth layer is an ordinary carbon fiber twill fabric, which is the upper surface layer. There are five layers in total. A certain vertical pressure is eve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com