Polishing abrasive tool, polishing device comprising polishing abrasive tool, and polishing method

A polishing device and polishing grinding technology, which is applied in the direction of grinding drive device, device for fixing grinding wheel, machine tool for surface polishing, etc. It can solve the problems of reducing the service life and processing quality of abrasive tools, impenetrable polishing, and low intermediate linear speed, etc. , to achieve the effects of easy promotion and realization, improved service life, and reduced line speed difference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

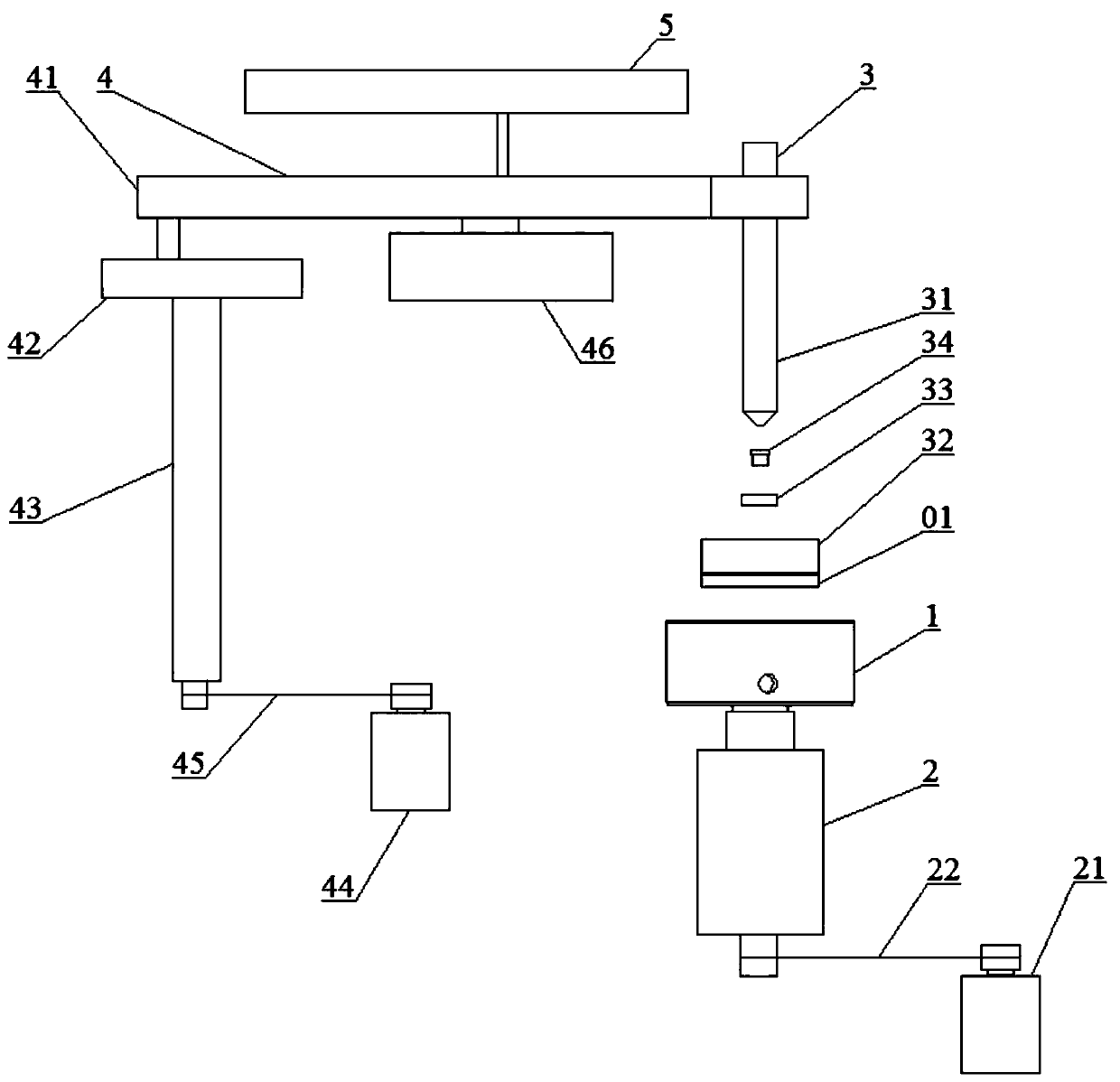

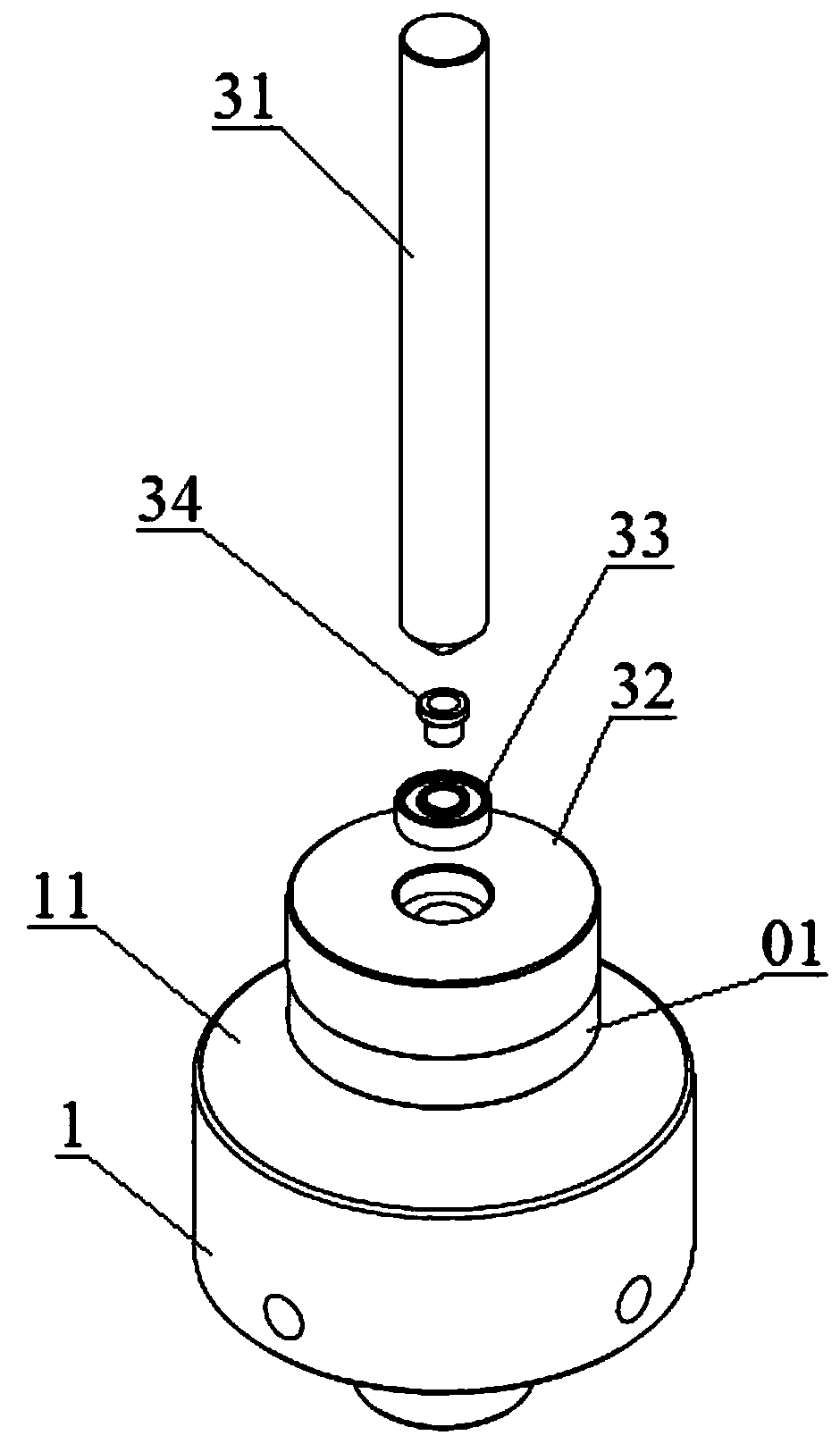

[0036] see Figure 1~4 , a polishing device, including a polishing abrasive 1, a rotating base 2, a positioning jig 3, a swing mechanism 4 and a pressure load mechanism 5.

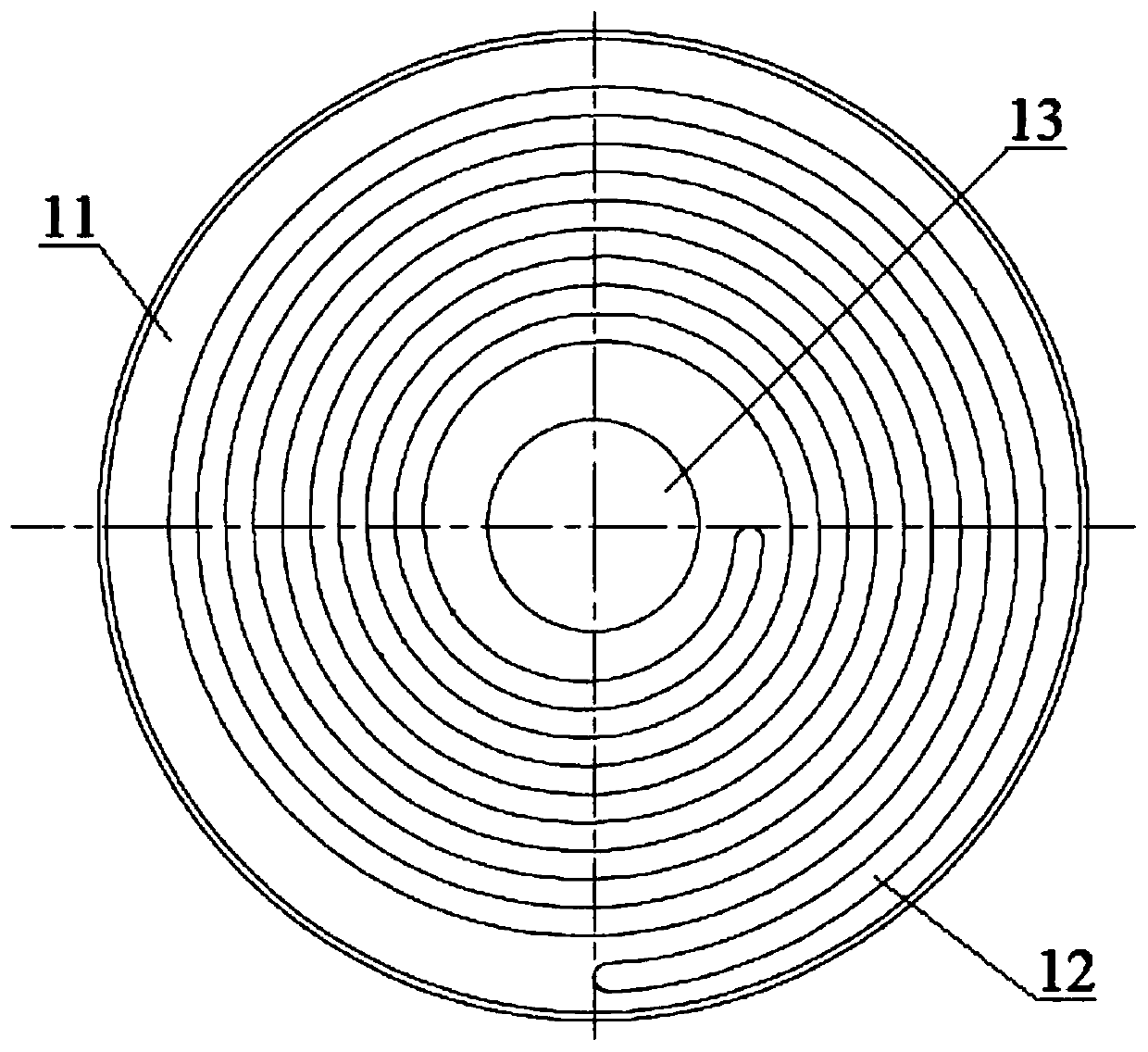

[0037] The polishing abrasive 1 is approximately cylindrical and includes an upwardly disposed polishing surface 11, on which a spiral groove 12 and a relief groove 13 are arranged, and the relief groove 13 is located at the center of the spiral groove 12 . The groove width of the spiral groove 12 is 2 mm, the groove depth is 3 mm, and the distance between adjacent grooves is 1 mm; the escape groove 13 is a circular groove with a diameter of 15 mm and a depth of 3 mm. The polishing surface 11 is a resin copper grinding head, which is prepared from a resin copper blank made of copper powder, diamond particles, resin binder and water after dry pressing, high temperature firing and CNC processing. In this embodiment , the working surface of the polishing surface 11 is designed into a planar structure accord...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com