Method for inhibiting generation of hydrogen sulfide during production of preserved vegetables

A technology of hydrogen sulfide and mustard, applied in climate change adaptation, food science and other directions, can solve problems such as hidden safety hazards, and achieve the effects of reduced harm, reduced production and wide source of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

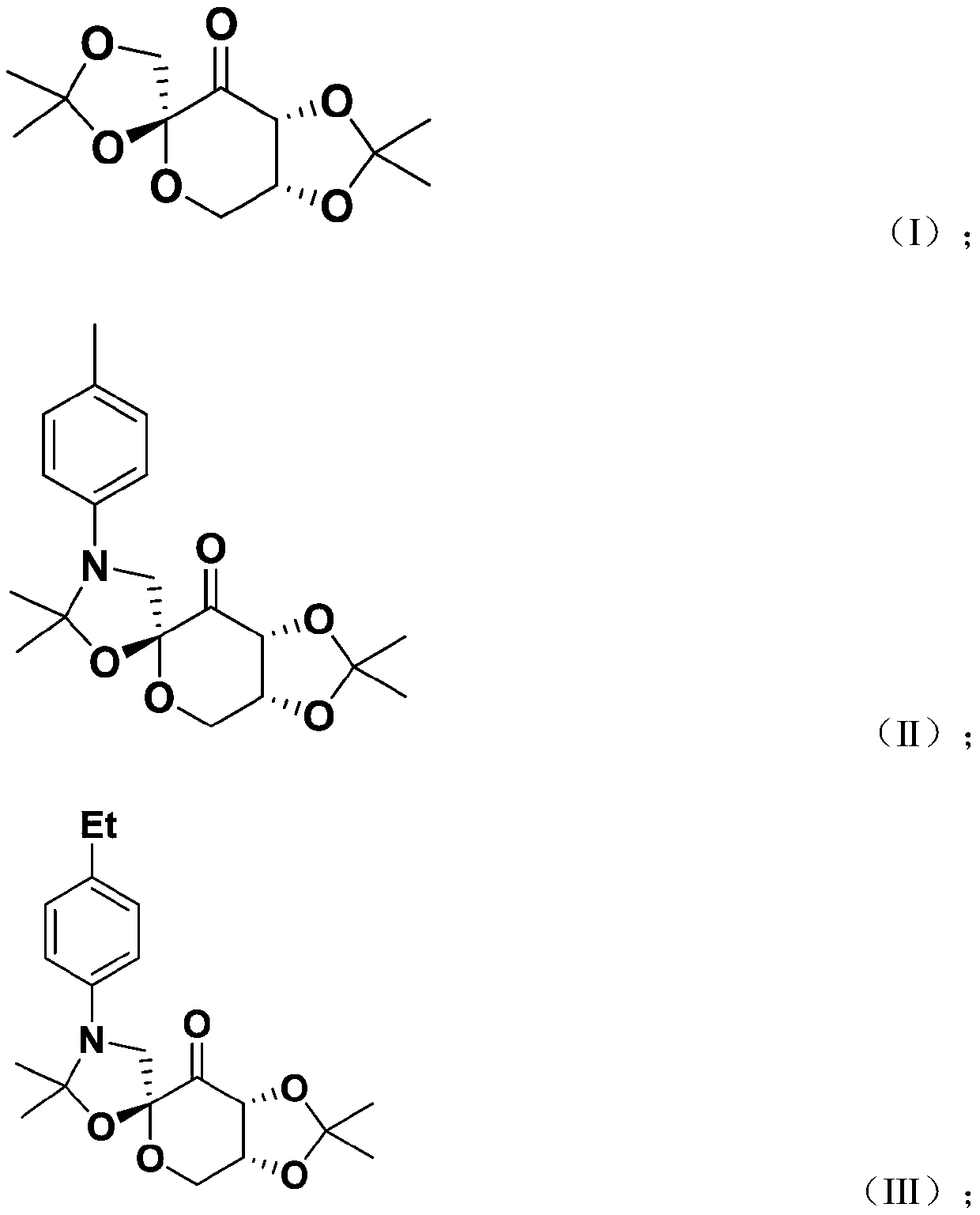

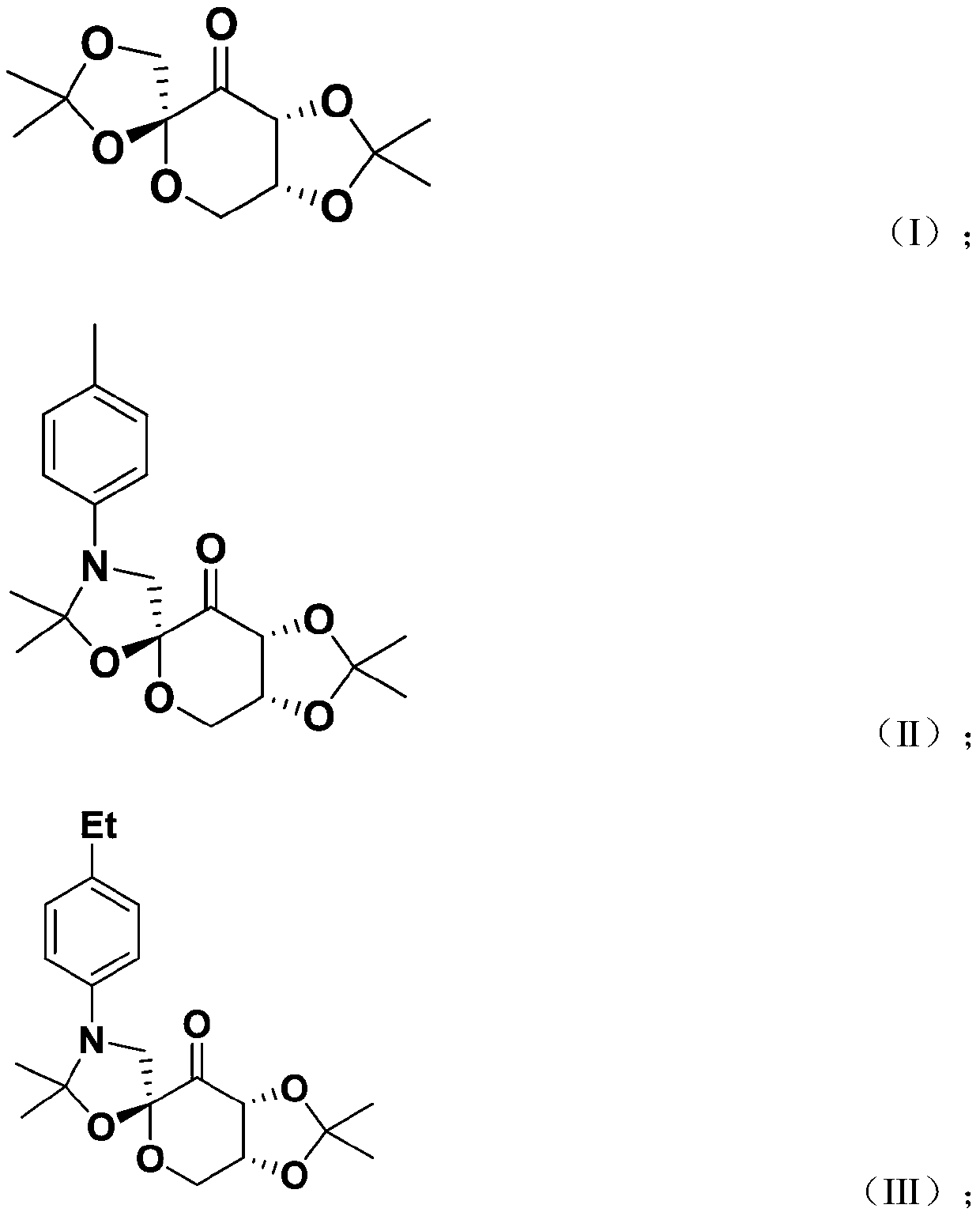

[0032] In the hydrogen sulfide inhibitor provided by the present invention, the synthetic method of No. 2 hydrogen sulfide inhibitor, its steps are as follows:

[0033] (1) Add 167mmol of D-glucose and 224mmol of p-methylaniline to a mixed solution of 9mL of water and 3.0mmol of acetic acid, heat the oil bath to 100°C and stir for 1 hour, then cool to room temperature;

[0034] (2) Add 300 mL of ethanol to the mixture to dilute, freeze at minus 25°C for 24 hours, filter, and wash the filter cake with a mixture of ethanol and ether at a volume ratio of 2:3 to obtain a white solid 1-p-toluidine-1-deoxy-D -fructose;

[0035] (3) Add 225.0 mmol of H to 72.0 mmol of 1-p-toluidine-1-deoxy-D-fructose and 146.0 mmol of trimethyl orthoformate in acetone at 0°C 2 SO 4 ;

[0036] (4) Stirring at 0°C for 2 hours, using NH 4 OH to terminate the reaction, filter, and concentrate, the resulting solid was 2 Cl 2 Dissolve and use Na 2 SO 4 Dry, filter again, and concentrate to about 50...

Embodiment 2

[0047] The synthetic method of No. 3 hydrogen sulfide inhibitor, its step is as follows:

[0048] (1) Add 167mmol of D-glucose and 224mmol of p-ethylaniline to a mixed solution of 9mL of water and 3.0mmol of acetic acid, heat the oil bath to 100°C and stir for 1 hour, then cool to room temperature;

[0049] (2) Add 300 mL of ethanol to the mixture to dilute, freeze at minus 25°C for 24 hours, filter, and wash the filter cake with a mixture of ethanol and ether at a volume ratio of 2:3 to obtain a white solid 1-p-ethylanilino-1-deoxy- D-fructose;

[0050] (3) Add 225.0 mmol of H to 72.0 mmol of 1-p-ethylanilino-1-deoxy-D-fructose and 146.0 mmol of trimethyl orthoformate in acetone at 0°C 2 SO 4 ;

[0051] (4) Stirring at 0°C for 2 hours, using NH 4 OH to terminate the reaction, filter, and concentrate, the resulting solid was 2 Cl 2 Dissolve and use Na 2 SO 4 Dry, filter again, and concentrate to about 50mL;

[0052] (5) Add boiling 150mL n-hexane to the above solution...

Embodiment 3

[0062] Use the No. 1 hydrogen sulfide inhibitor that buys to suppress and produce hydrogen sulfide situation in mustard mustard production process and carry out experiment, and its steps are as follows:

[0063] (1) Clean the fresh green head vegetables;

[0064] (2) Put the cleaned mustard raw material into the vegetable pond, add salt according to the ratio of 2-8% (preferably 4%) and marinate for 2-3 days, preferably to obtain semi-finished mustard mustard, add 0.1%-0.5 % (preferably 0.5%) hydrogen sulfide inhibitor;

[0065] (3) pull out mustard mustard raw material, wash desalination with a large amount of water;

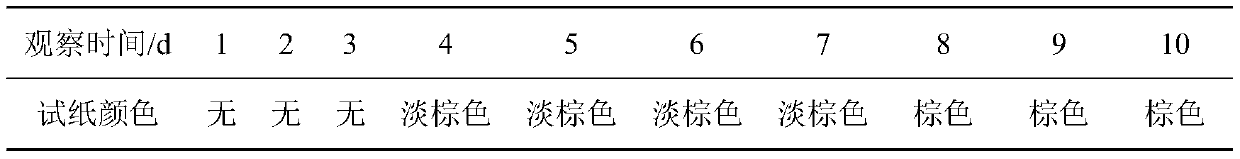

[0066] (4) Mix 0.1% to 0.2% (preferably 0.15%) No. 1 inhibitor with the desalted mustard raw material and put it into a plastic film bag, vacuumize, and seal and ferment for 10 days at 25°C; use it every other day Use tweezers to put the lead acetate test paper soaked in water into the vacuum bag, and observe whether the test paper changes color and the depth...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com