Bipedal clamping type high bearing precise piezoelectric linear driver

A linear drive, linear drive technology, applied in piezoelectric effect/electrostrictive or magnetostrictive motors, generators/motors, electrical components, etc., can solve complex preload adjustment, poor load capacity, low resolution and other problems, to achieve the effect of simple structure, strong load capacity and high resolution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

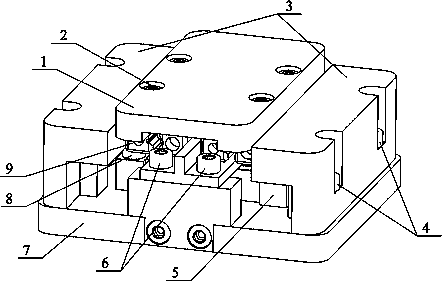

[0029] Specific implementation mode one: combine Figure 1~Figure 14 To illustrate this embodiment, this embodiment provides a specific implementation of a biped-clamped high-load precision piezoelectric linear actuator, and the specific implementation of the biped-clamped high-load precision piezoelectric linear actuator is expressed as follows:

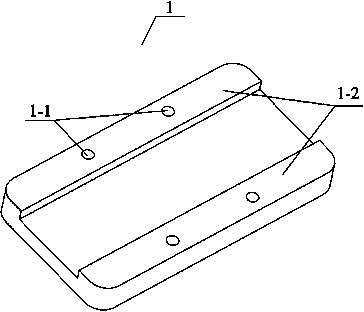

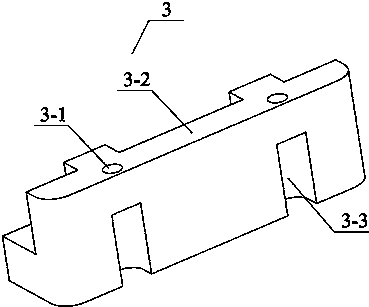

[0030]The two-foot clamping high-load precision piezoelectric linear actuator is mainly composed of a sliding upper plate 1, a sliding upper plate mounting bolt 2, a package cover 3, a package cover fixing bolt 4, a linear drive stator 5, and a guide rail assembly fixing bolt 6 , a base assembly 7, a linear drive stator fixing bolt 8, and a guide rail assembly 9; wherein, the sliding upper plate 1 is installed on the guide rail assembly 9 through the sliding upper plate mounting bolts 2, and the packaging cover 3 is fixed through the packaging cover fixing bolts 4. Fixedly installed on the base assembly 7, the linear drive stator 5 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com