Lithium battery pack shell and lithium battery pack specialized for industrial vehicle

A lithium battery pack and battery shell technology, applied in the direction of battery/battery traction, battery pack parts, batteries, etc., can solve the problems of easily damaged electrode contact blocks, and the battery pack is prone to up and down shaking, etc., to eliminate vibration shock, The effect of protecting the battery pack

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0024] see Figure 1 to Figure 5 , the present invention provides a technical solution:

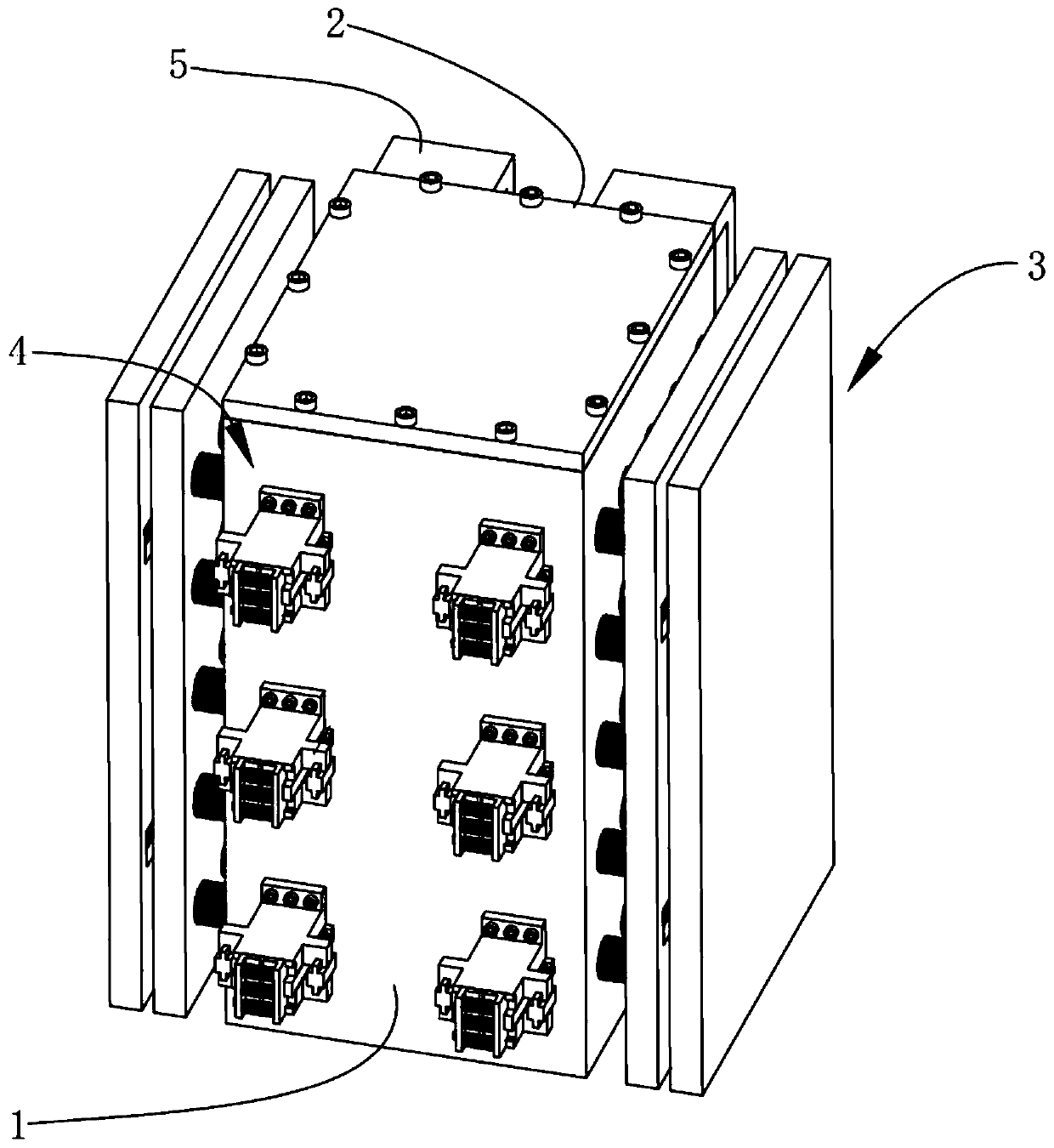

[0025] A lithium battery pack casing, including a battery case 1, a cover plate 2, a side shock absorbing mechanism 3, a connecting mechanism 4 and a connecting frame 5, the cover plate 2 is sealed and installed on the top of the battery case 1 by bolts, wherein:

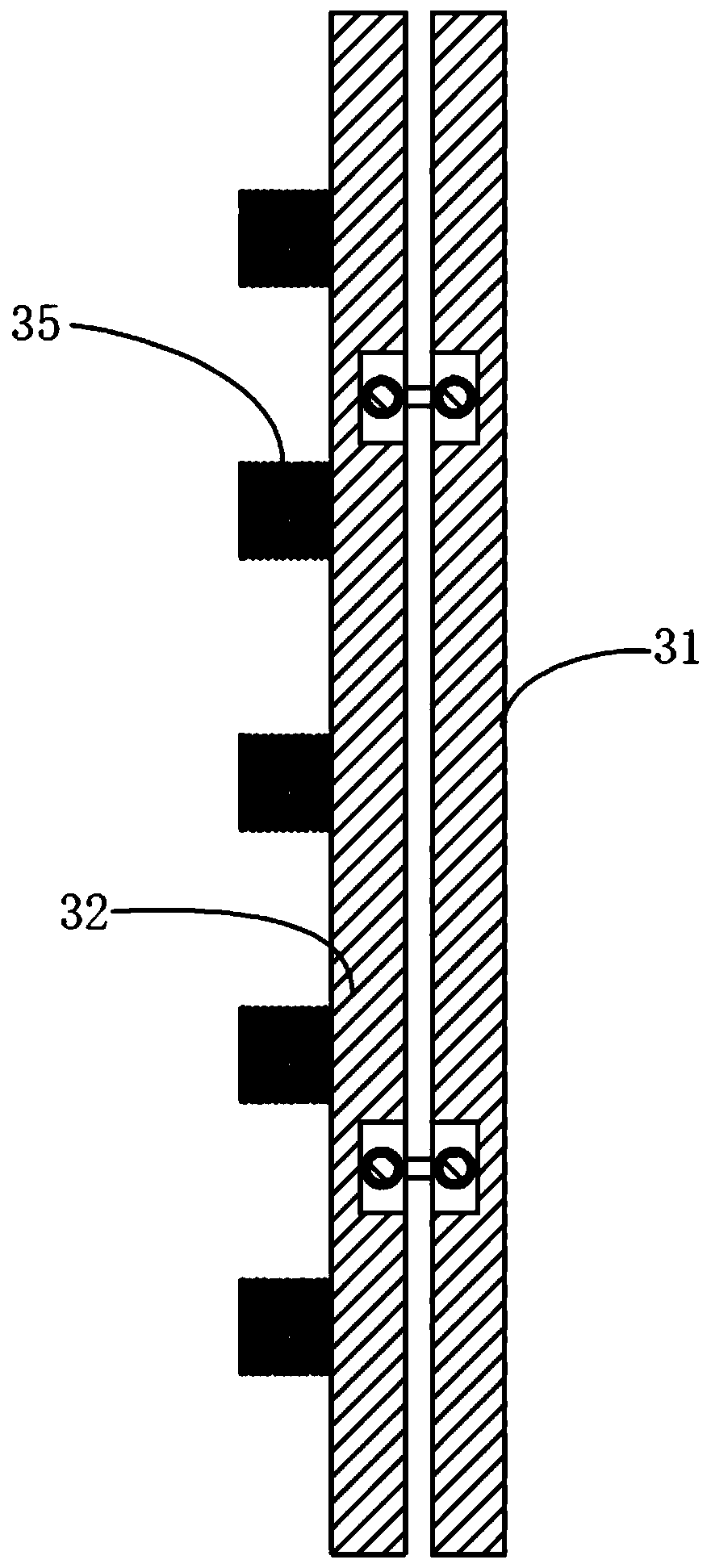

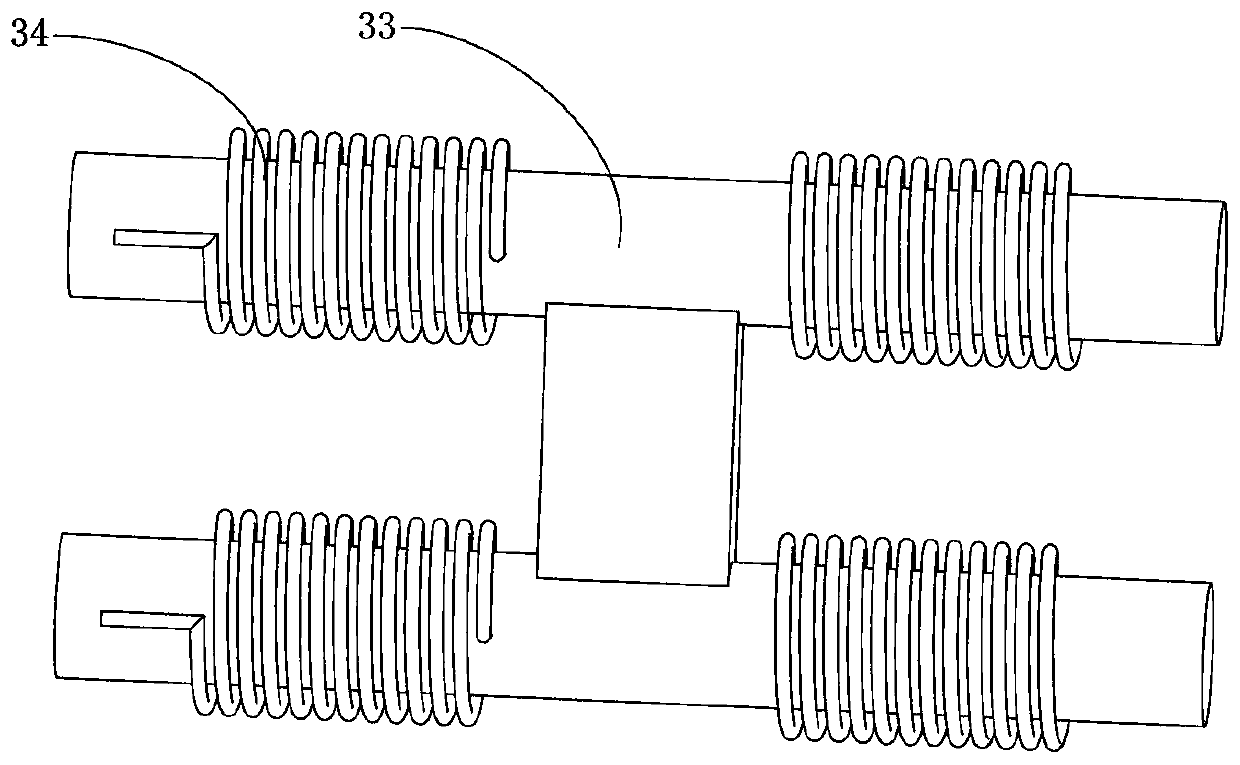

[0026] The two side damping mechanisms 3 are respectively located on both sides of the battery case 1. The side damping mechanisms 3 include a bottom plate 31, a top plate 32, an I-shaped connecting frame 33, a torsion spring 34 and a spring I35. The bottom plate 31 is installed on the battery case through several springs I35. The side of the battery case 1, wherein the two ends of the spring I35 are fixedly connected with the bottom plate 31 and the side of the battery case 1 respectively, and the spring I35 can effectively reduce the impact on the battery case 1, and the top plate 32 rotates through several I-shaped connectin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com