Industrial robot absorbing fixture

A technology of industrial robots and adsorption fixtures, applied in the direction of manufacturing tools, chucks, manipulators, etc., can solve the problems of single structure, poor practicability, lack of protection, etc., and achieve the effect of excellent structure, fast transportation, and strong practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

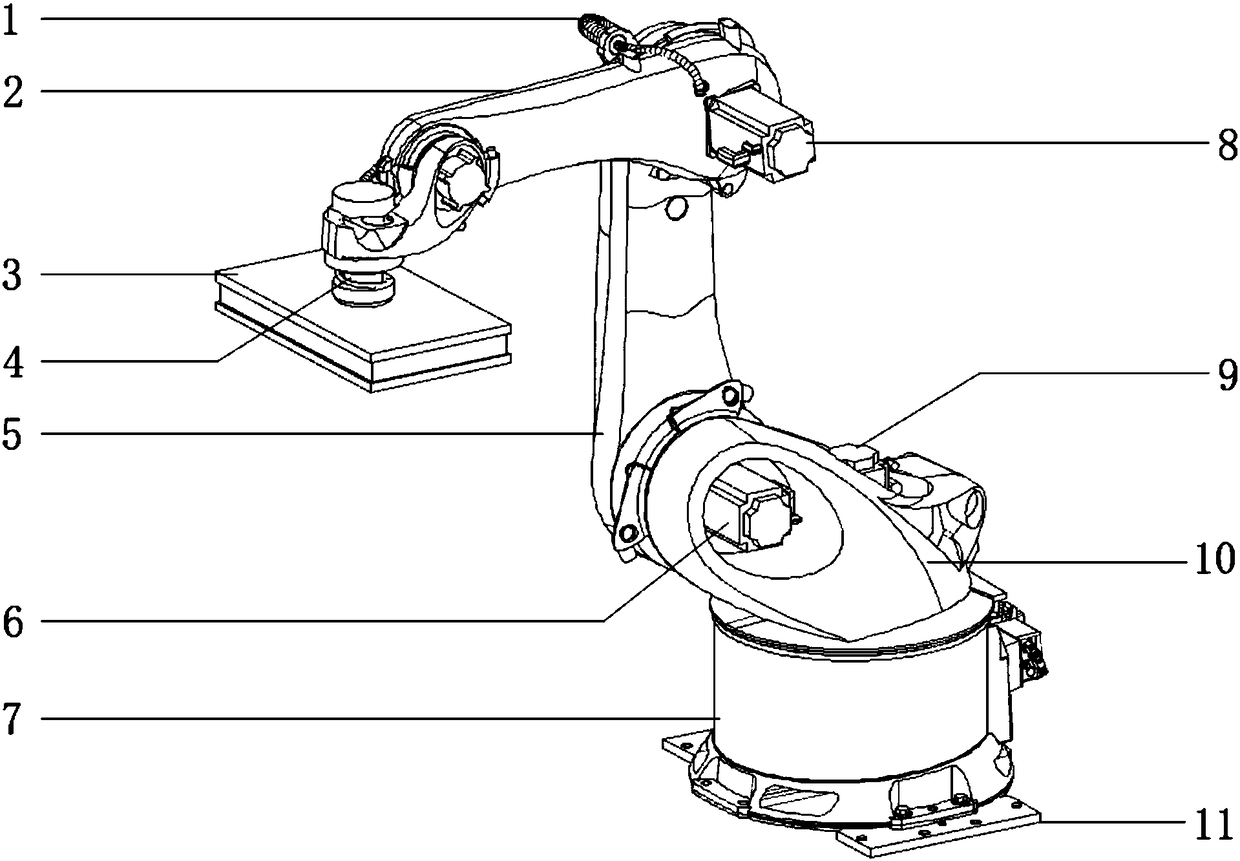

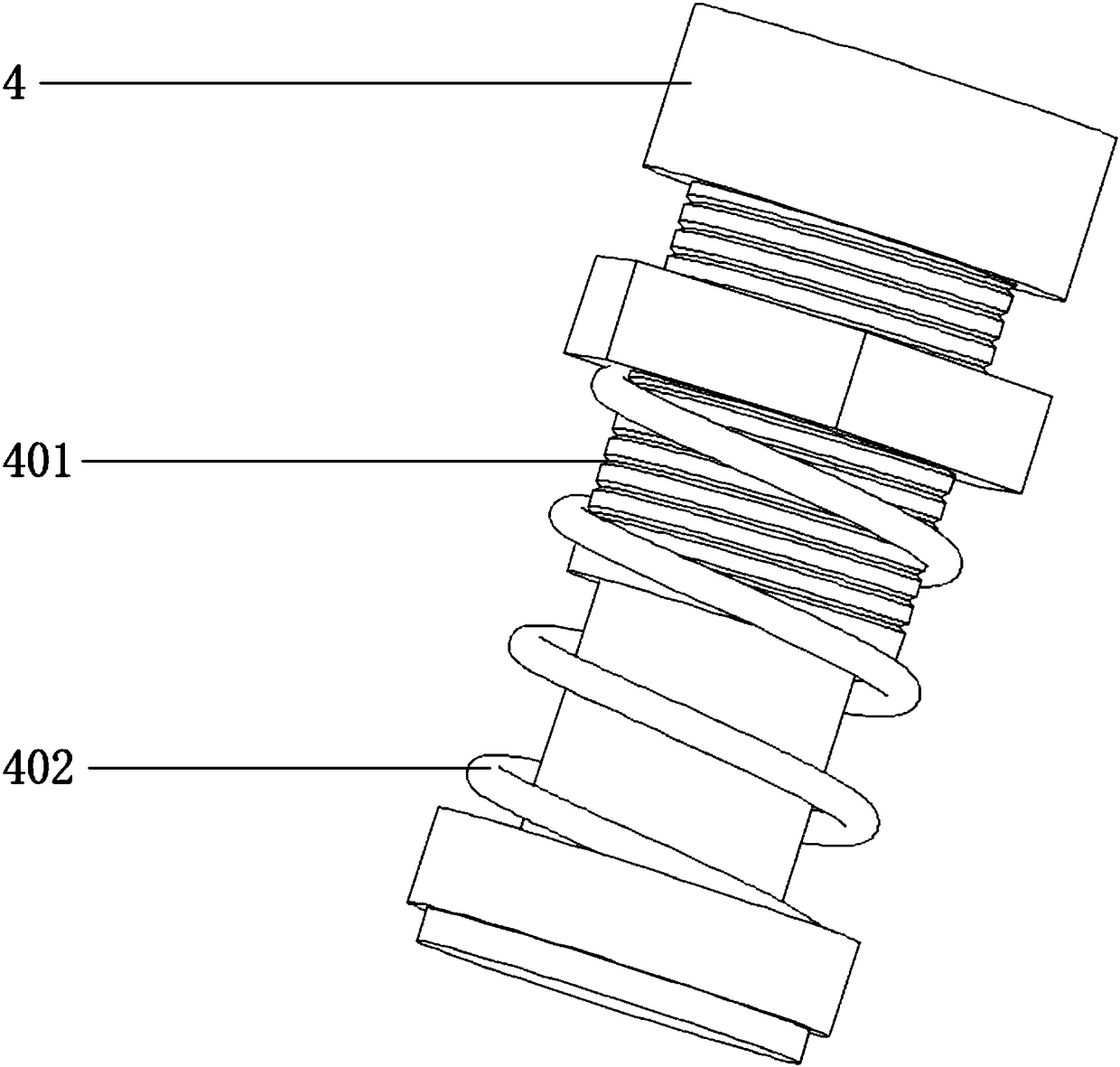

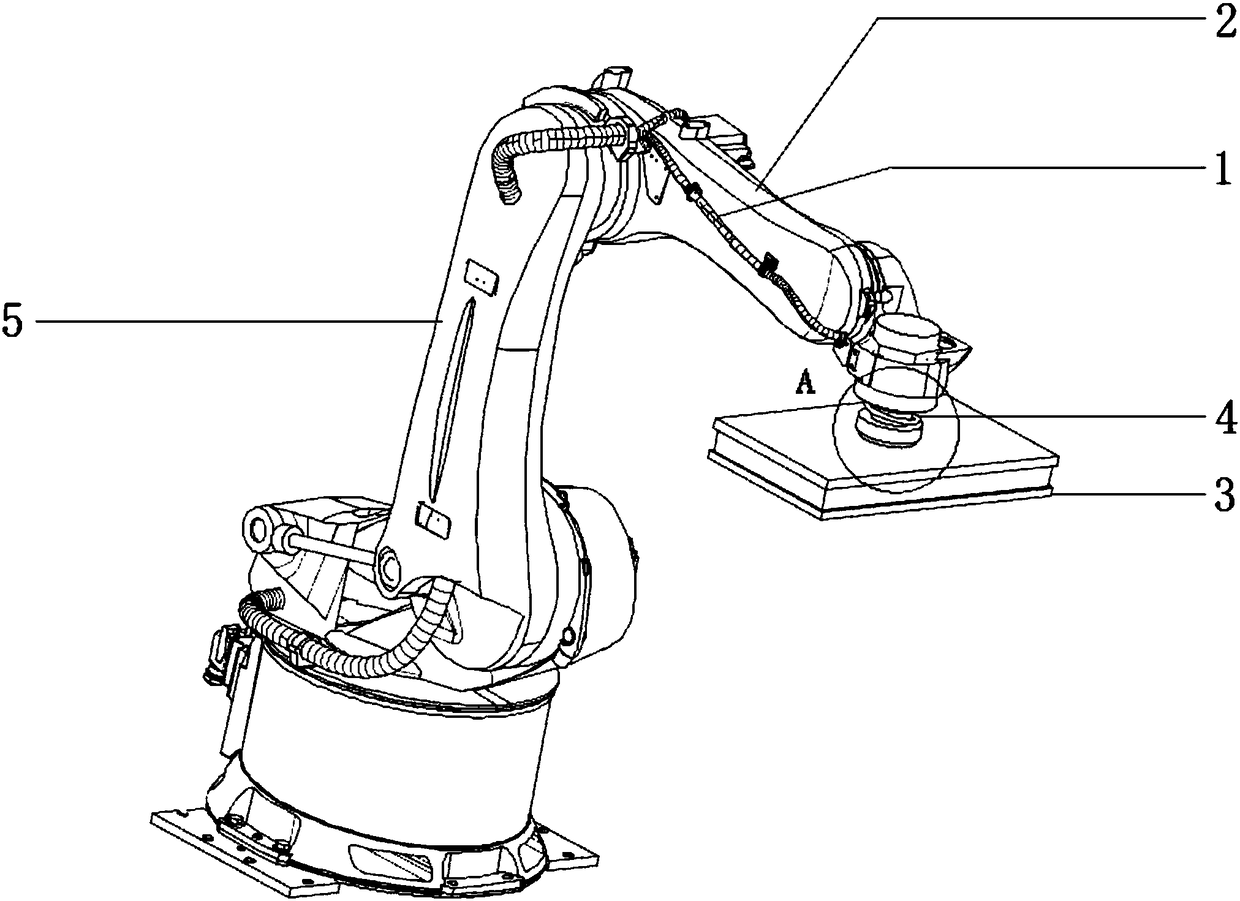

[0029] An adsorption fixture for an industrial robot, comprising: a grommet 1, a first connecting rod 2, an electromagnetic chuck 3, a shock absorber 4, a second connecting rod 5, a second connecting rod motor 6, a base 7, and a first connecting rod motor 8. The third connecting rod motor 9, the third connecting rod 10, the mounting frame 11, the damper 401, and the damping spring 402; A third connecting rod 10 connected by a clearance fit is provided; a third connecting rod motor 9 connected by a bolt screw connection is arranged inside the third connecting rod 10, and the inner left side of the third connecting rod 10 is provided with The second connecting rod motor 6 connected by bolt screw connection; the rear left part of the third connecting rod 10 is provided with the second connecting rod 5 connected by clearance fit, and the front upper part of the second connecting rod 5 is provided There is a first connecting rod 2 connected by clearance fit; the inner right side of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com