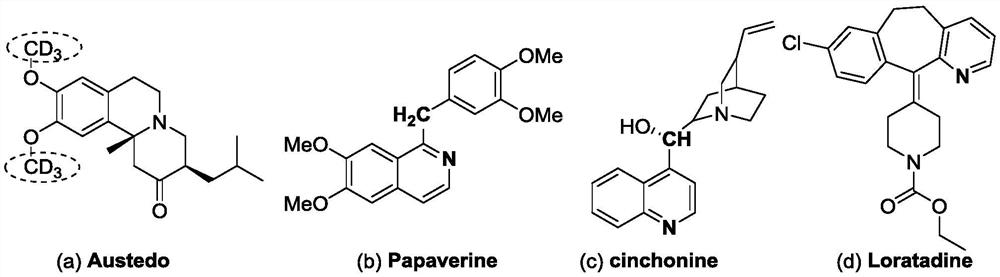

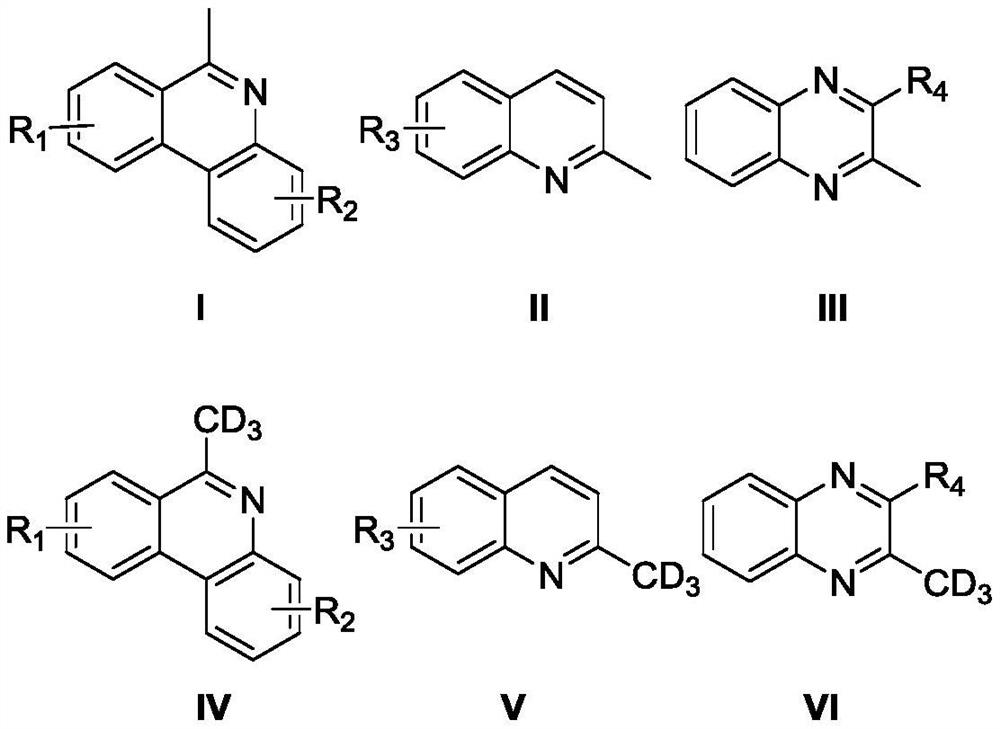

A highly selective deuteration method for 2-methyl nitrogen heterocyclic compounds

A technology of compounds and heterocycles, applied in the field of synthesis of organic compounds, can solve problems such as limited application and general chemical selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

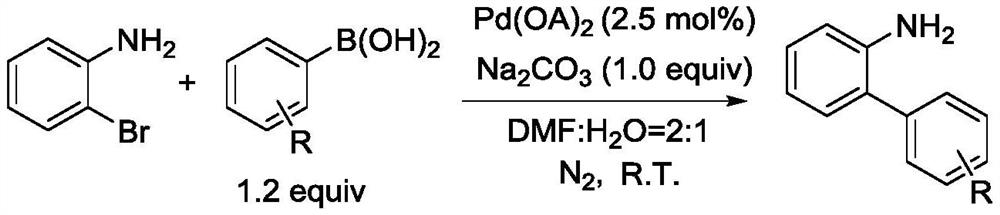

Method used

Image

Examples

Embodiment 1

[0036]

[0037] 6-Methylphenanthridine (0.3 mmol, 58 mg), iodobenzene diacetate (0.45 mmol, 144.9 mg), and azobisisobutyronitrile (0.15 mmol, 24.6 mg) were added to a dry Schlenk reaction tube, which was replaced by vacuum. Under nitrogen protection three times, deuterium water (300 μL) and N,N-dimethylformamide (3 mL) were added to the above reaction tube, and the reaction tube was stirred at 100° C. for 12 hours. After the reaction, 10 mL of water was added to the obtained reaction solution, extracted with diethyl ether, the organic layer was collected, dried with anhydrous sodium sulfate, filtered, the filtrate was taken, and the solvent was evaporated to obtain 6-(methyl-d3)phenanthridine, which produced The rate of deuterium is 65%, and the rate of deuterium is 79%.

[0038] Characterization data: 1 H NMR (500MHz, CDCl 3 )δ8.54-8.51(m,1H),8.47-8.44(m,1H), 8.14-8.10(m,1H),8.09(dd,J1=8.1Hz,J2=1.0Hz,3H),7.75(m ,3H),7.70-7.66(m,1H),7.63-7.60(m,1H),7.59-7.55(m,1H),2.97(m...

Embodiment 2

[0040]

[0041] 8-Fluoro-6-methylphenanthridine (0.3 mmol, 63.3 mg), potassium persulfate (0.45 mmol, 121.6 mg), azobisisobutyronitrile (0.15 mmol, 24.6 mg) were added to a dry Schlenk reaction tube , evacuated and changed nitrogen three times. Under nitrogen protection, deuterium water (300 μL) and N,N-dimethylformamide (3 mL) were added to the above reaction tube, and the reaction tube was stirred and reacted at 100° C. for 12 hours. After the reaction, 10 mL of water was added to the obtained reaction solution, extracted with ether, the organic layer was collected, dried with anhydrous sodium sulfate, filtered, the filtrate was collected, and the solvent was evaporated to obtain 8-fluoro-6-(methyl-d3) Phenanthridine, 75% yield, 34% deuterated yield.

[0042] Characterization data: 1 H NMR (500MHz, CDCl 3 )δ8.57(dd,J 1 =9.1Hz,J 2 =5.3Hz,1H), 8.44(d,J=8.2Hz,1H), 8.09(dd,J 1 =8.2Hz,J 2 =1.1Hz,1H),7.78(dd,J 1 = 9.6 Hz, J 2 = 2.5Hz, 1H), 7.72-7.66(m, 1H), 7.64-7.58(m,...

Embodiment 3

[0044]

[0045] 9-tert-Butyl-6-methylphenanthridine (0.3 mmol, 74.8 mg), ceric ammonium nitrate (0.45 mmol, 246.7 mg), azobisisobutyronitrile (0.15 mmol, 24.6 mg) were added to the dry Schlenk reaction The tube was evacuated and replaced with nitrogen three times. Under nitrogen protection, deuterium water (300 μL) and N,N-dimethylformamide (3 mL) were added to the above reaction tube, and the reaction tube was stirred at 100 ° C for 12 Hour. After the reaction, 10 mL of water was added to the obtained reaction solution, extracted with ether, the organic layer was collected, dried with anhydrous sodium sulfate, filtered, the filtrate was collected, and the solvent was evaporated to obtain 9-tert-butyl-6-(methyl- d3) Phenanthridine, yield 69%, deuteration rate 84%. Characterization data: 1 H NMR (500MHz, CDCl 3 )δ8.57-8.50(m,2H),8.18(d,J=1.9Hz,1H),8.13(dd,J 1 =8.2Hz,J 2 =1.0Hz,1H),7.93(dd,J 1 =8.7Hz,J 2 = 2.0Hz, 1H), 7.72-7.69(m, 1H), 7.65-7.58(m, 1H), 3.09-3.06(m, 0....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com