Ball-milling synthetic method of aluminum sulfide

A synthesis method, aluminum sulfide technology, applied in the direction of aluminum sulfide, aluminum sulfur compounds, etc., to achieve the effect of reducing costs, reducing tail gas treatment links, and high purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

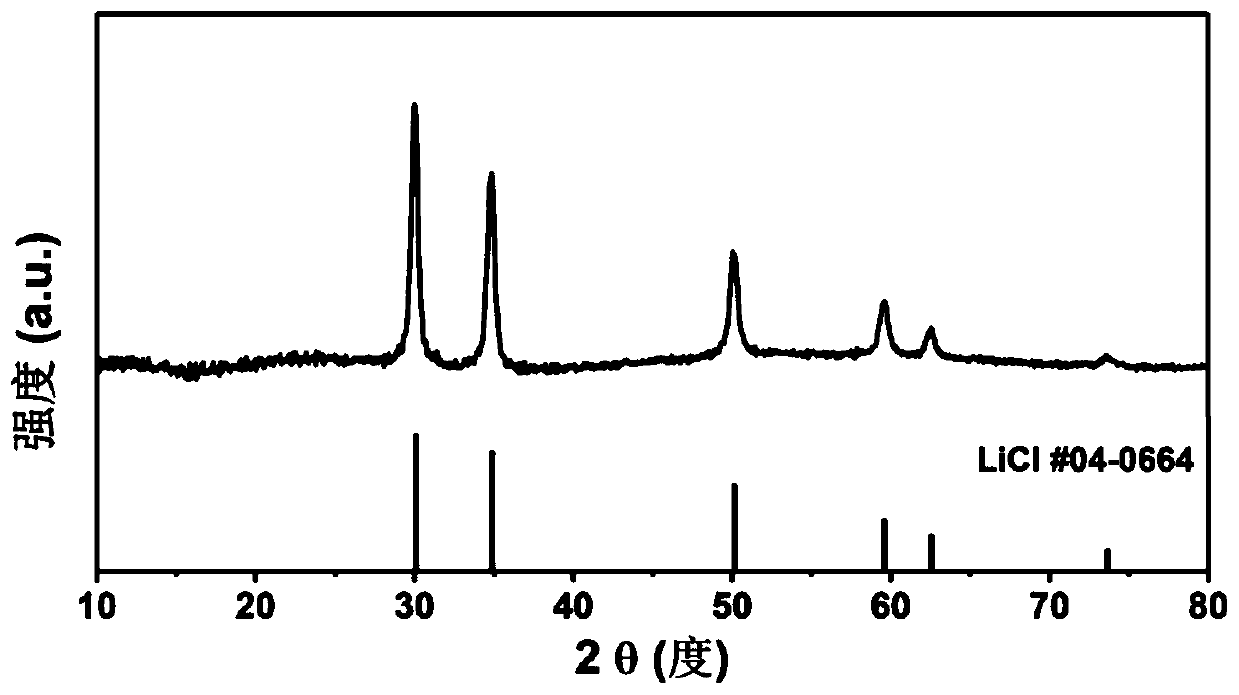

[0026] Take 0.58g of aluminum chloride and 0.3g of lithium sulfide powder, pour them into a mortar, grind and disperse evenly, put them into a ball mill jar, and then put the balls into the ball mill jar, wherein the ball-to-material ratio is 30:1, and the ball mill speed 500r / min, ball milling for 12 hours, after the ball milling, pour the obtained solid powder into absolute ethanol, then separate the solid and liquid by filtration, wash the solid powder three times with absolute ethanol, and finally put the solid at 60°C Drying at a lower temperature yields aluminum sulfide powder. The XRD figure of embodiment 1 reaction product is as follows figure 1 As shown, there is only the XRD peak of LiCl in the reaction product, and no XRD peak of other substances is observed. According to the type and number of atoms before and after the chemical reaction, there must be Al in the product. 2 S 3 produce. XRD picture as shown figure 1 shown.

Embodiment 2

[0028] Take 0.58g of aluminum chloride and 0.3g of lithium sulfide powder, pour them into a mortar, grind and disperse evenly, put them into a ball mill jar, and then put the balls into the ball mill jar, wherein the ball-to-material ratio is 50:1, and the ball mill speed 400r / min, ball milling for 12 hours, after the ball milling, pour the obtained solid powder into absolute ethanol, then separate the solid and liquid by filtration, wash the solid powder three times with absolute ethanol, and finally put the solid at 80°C Drying at a lower temperature yields aluminum sulfide powder.

Embodiment 3

[0030] Take 0.58g of aluminum chloride and 0.3g of lithium sulfide powder, pour them into a mortar, grind and disperse evenly, put them into a ball mill jar, and then put the balls into the ball mill jar, wherein the ball-to-material ratio is 40:1, and the ball mill speed 500r / min, ball milling for 24 hours, after the ball milling, pour the obtained solid powder into absolute ethanol, then separate the solid and liquid by filtration, wash the solid powder three times with absolute ethanol, and finally put the solid at 90°C Drying at a lower temperature yields aluminum sulfide powder.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com