Pulp washer

A pulp washing machine and pulp feeding technology, applied in washing/replacing pulp treatment liquid, pulp dewatering, etc., can solve the problems of filter screen breakage, low filter screen life, tearing, etc., so as to reduce pulping costs and improve production efficiency. , the effect of long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] Below in conjunction with the accompanying drawings, the present invention will be described in detail through specific embodiments, but the use and purpose of these exemplary embodiments are only used to illustrate the present invention, and do not constitute any form of any limitation on the actual protection scope of the present invention, let alone The protection scope of the present invention is limited thereto.

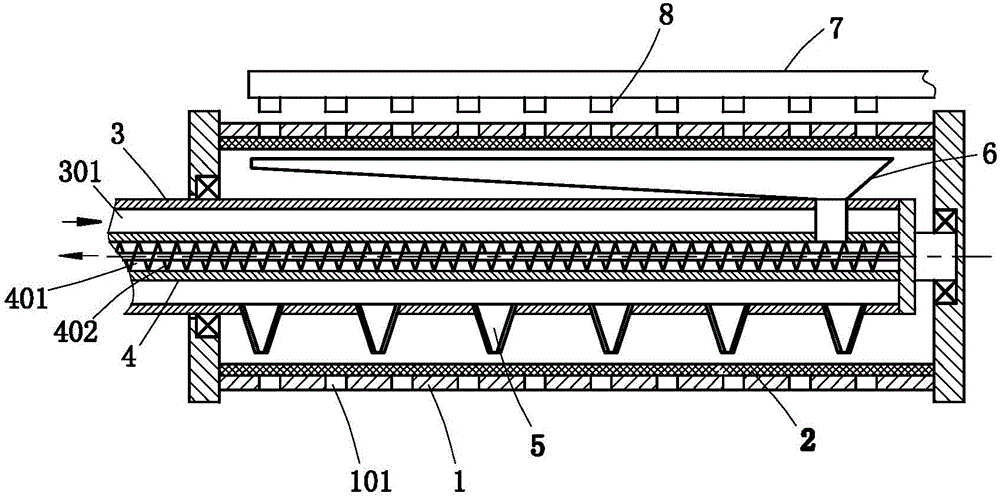

[0016] The arrows in the figure indicate the direction of pulp inlet and outlet.

[0017] like figure 1 As shown, the pulp washing machine of the present invention includes a rotating drum 1 driven by a power device and rotated in the axial direction. The power device includes a motor, and a ring gear is arranged on the outer surface of the drum 1. The gears meshing with each other drive the drum 1 to rotate through the motor, and dewater and wash pulp by centrifugal force. The axis of the drum 1 is set horizontally. A filter screen 2 is fixedly install...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com