Machining numerical-control milling machine for alloy frame manufacturing based on bidirectional alignment principle

A CNC milling machine and principle technology, applied in the direction of manufacturing tools, metal processing equipment, metal processing mechanical parts, etc., can solve the problems of corner gaps, unevenness, affecting the aesthetic quality of products, etc., to avoid angle errors, improve aesthetics and quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

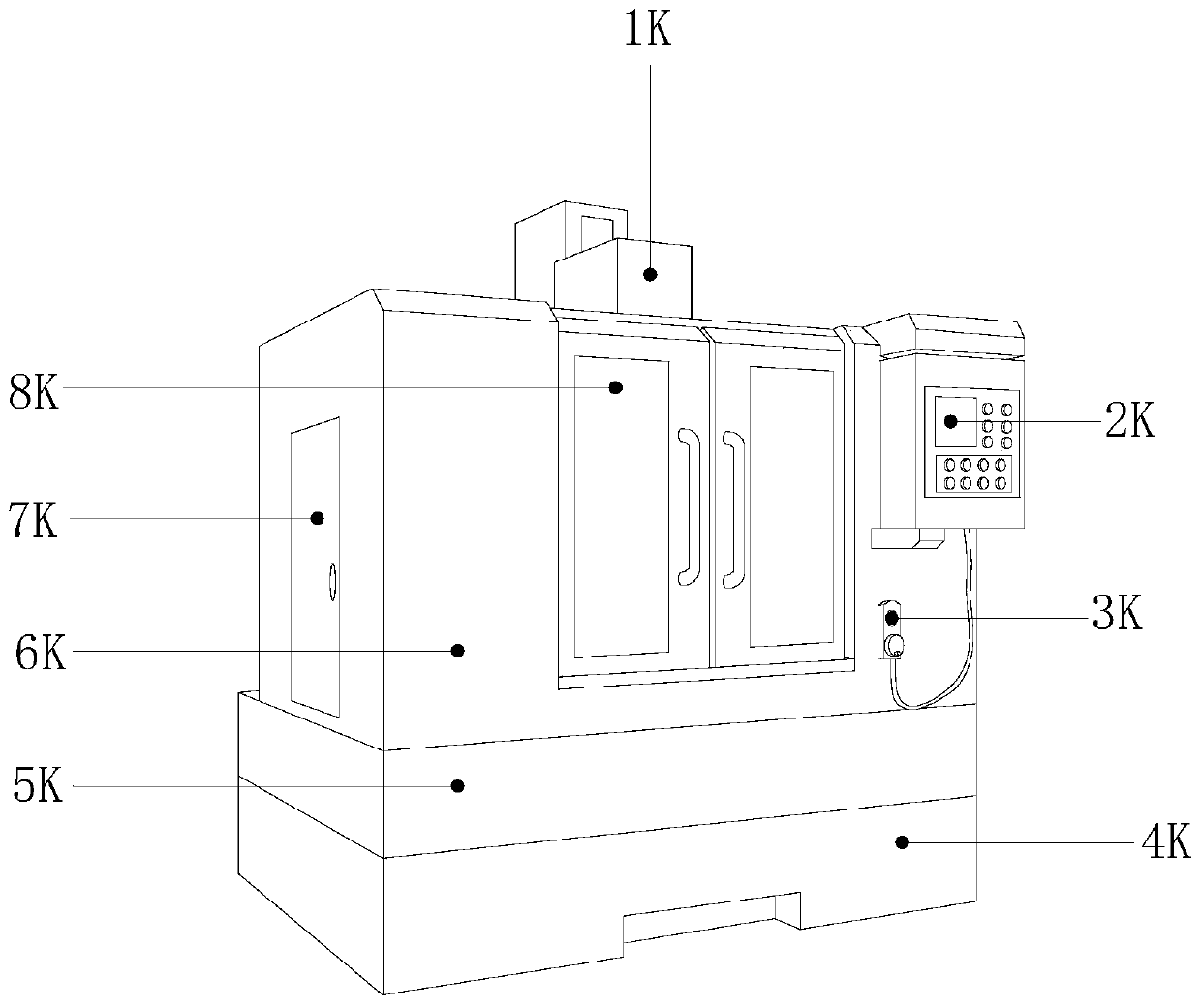

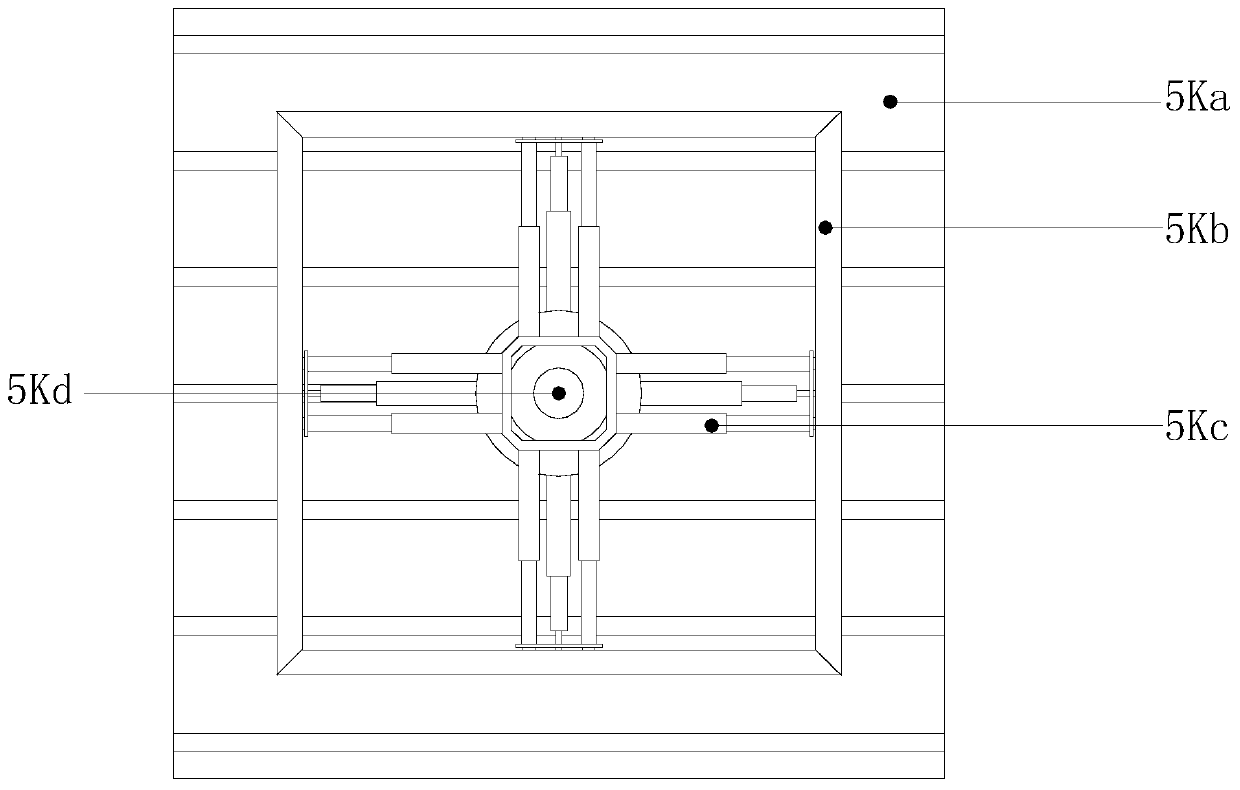

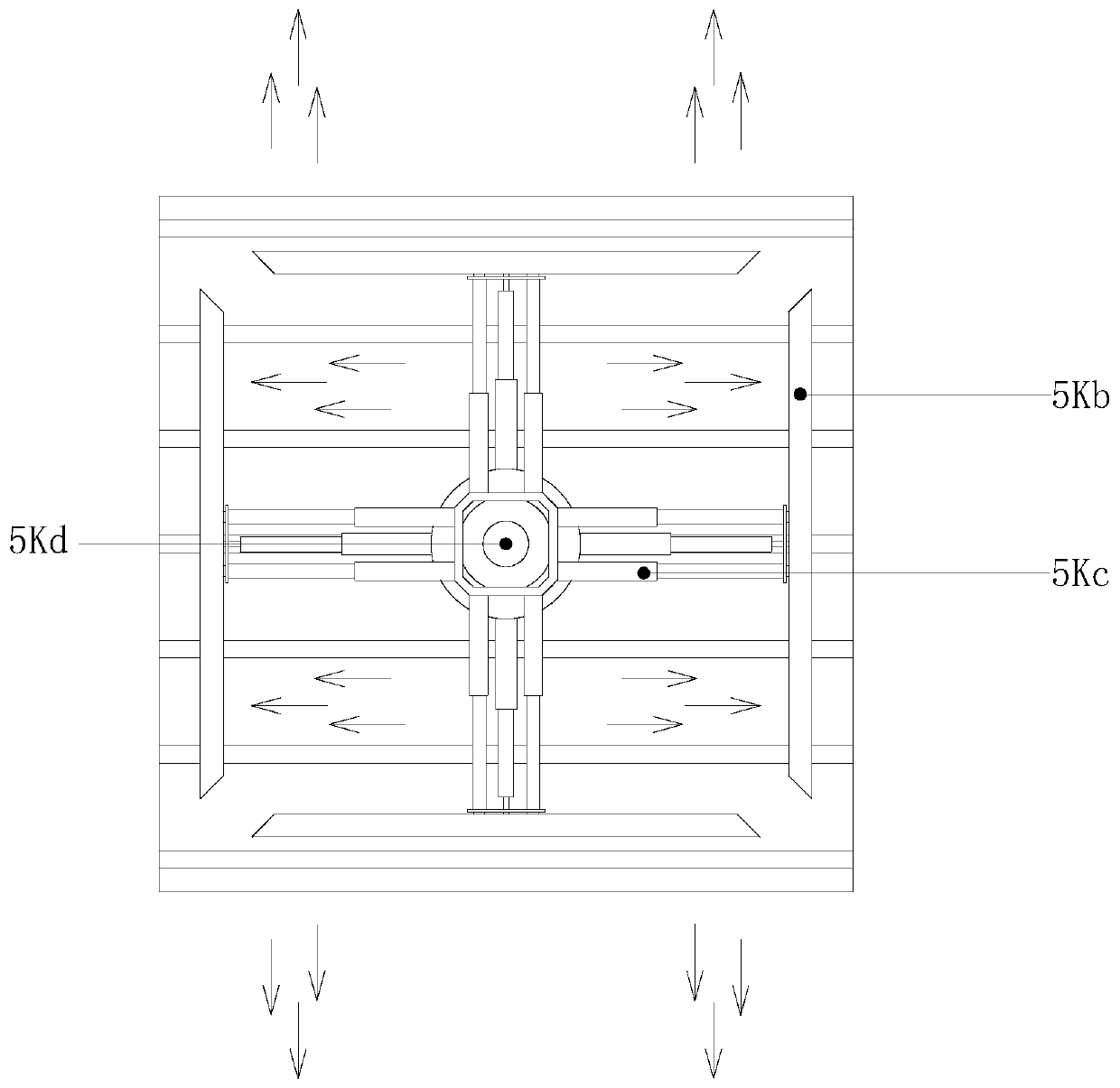

[0030] see Figure 1-Figure 7 , the present invention provides a CNC milling machine for alloy frame manufacturing based on the principle of two-way positioning. Its structure includes a main shaft 1K, a control panel 2K, a control handwheel 3K, a cooling water tank 4K, a processing platform 5K, a processing chamber 6K, and an inspection door 7K , the protective door 8K, the protective door 8K is installed in the middle of the front end of the processing chamber 6K by embedding, the left side of the processing chamber 6K is provided with an inspection door 7K, the processing platform 5K is a rectangular structure, and is located at the bottom of the processing chamber 6K, The cooling water tank 4K is installed on the bottom of the processing platform 5K by embedding, the upper right end of the processing chamber 6K is provided with a control panel 2K, and is connected by buckling, and the control hand wheel 3K is arranged on the right end of the surface of the processing chambe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com