Propylene gas catalytic deoxidation device with temperature and tail gas oxygen concentration control and method

A technology of gas catalysis and propylene, which is applied in chemical instruments and methods, gas treatment, separation methods, etc., and can solve problems such as fluctuations in oxygen content, flying temperature of the catalytic bed layer, excessive tail oxygen content, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

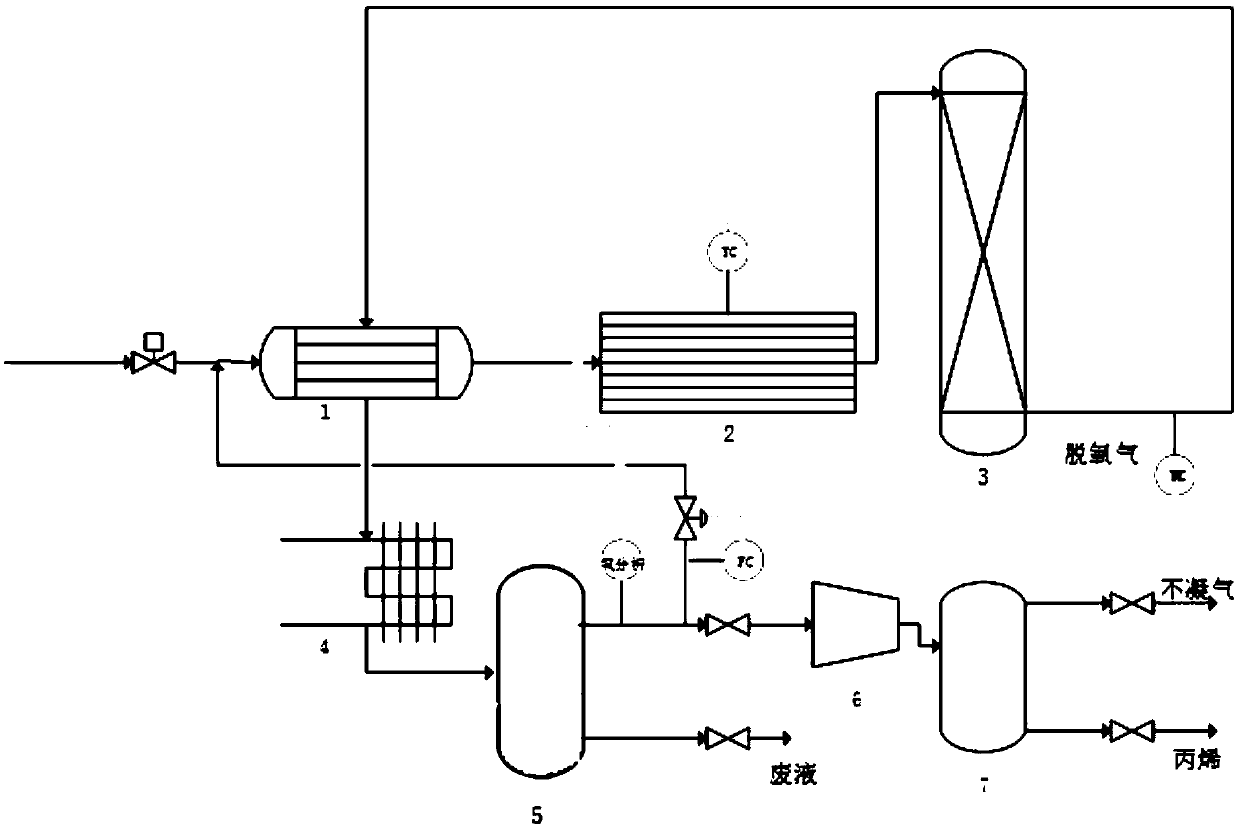

Image

Examples

Embodiment 1

[0044] Composition of propylene tail gas: the concentration of oxygen by volume is 5%, the concentration of propylene by volume is 90%, and the concentration of nitrogen is 5%. Reaction pressure 1MPa, reaction space velocity 10000hr -1 . The propylene tail gas is at 40°C, and after the heat is exchanged to 80°C by the heat exchanger, it enters the deoxygenation reactor, and the outlet temperature of the reaction bed is 280°C. The gas after the deoxygenation reaction exchanges heat with the raw material gas to 80°C, and after being cooled to 20°C by the air condenser, it enters the gas-liquid separation tank to separate the liquid phase generated during the reaction. The gas phase oxygen content is 0.1%, and the gas phase oxygen content gradually increases to 0.17% during operation. After the reaction inlet temperature is increased to 130°C, the gas phase oxygen content will drop to 0.14%, and the operation is maintained under this operating condition.

Embodiment 2

[0046] Composition of propylene tail gas: the concentration of oxygen by volume is 3.5%, the concentration of propylene by volume is 90%, and the concentration of nitrogen is 6.5%. Reaction pressure 3MPa, reaction space velocity 30000hr -1 . The propylene tail gas is at 40°C, and after the heat is exchanged to 380°C by the heat exchanger, it enters the deoxygenation reactor, and the outlet temperature of the reaction bed is 535°C. The gas after the deoxygenation reaction exchanges heat with the raw material gas to 120°C, and after being cooled to 20°C by the air 4 condenser, it enters the gas-liquid separation tank to separate the liquid phase generated during the reaction. The gas phase oxygen content is 0.18%, the reaction inlet temperature is increased to 390°C, the reaction bed outlet temperature is raised to 545°C, and the gas phase oxygen content is reduced to 0.16%; the reaction inlet temperature is further increased to 400°C, and the reaction bed outlet temperature is...

Embodiment 3

[0048] Composition of propylene tail gas: oxygen volume percentage concentration is 4.6%, propylene volume percentage concentration is 90%, nitrogen gas 5.4%. Reaction pressure 3MPa, reaction space velocity 30000hr -1 . The propylene tail gas is at 40°C, and after the heat is exchanged to 385°C by the heat exchanger, it enters the deoxygenation reactor, and the outlet temperature of the reaction bed is 595°C. The gas after the deoxidation reaction exchanges heat with the raw material gas to 130°C, and after being cooled to 20°C by the air condenser, it enters the gas-liquid separation tank to separate the liquid phase generated during the reaction. The oxygen content of the gas phase is 0.11%. At this time, the reactor The outlet temperature control is started, the reflux regulating valve is opened, and 40% of the gas reflux is controlled. The reactor outlet temperature will be 520°C, and the gas phase oxygen content will be 0.19%; adjust the reaction temperature to 540°C, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com