Automatic condensation water return system

A technology for automatic water return and condensate water, applied in the direction of supplementary water supply, feedwater heater, preheating, etc., can solve the problems of consumption, high power and maintenance force, and high failure rate of condensate pump operation, achieve uniform water flow velocity, reduce equipment The effect of malfunction, simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Further illustrate the present invention below in conjunction with accompanying drawing.

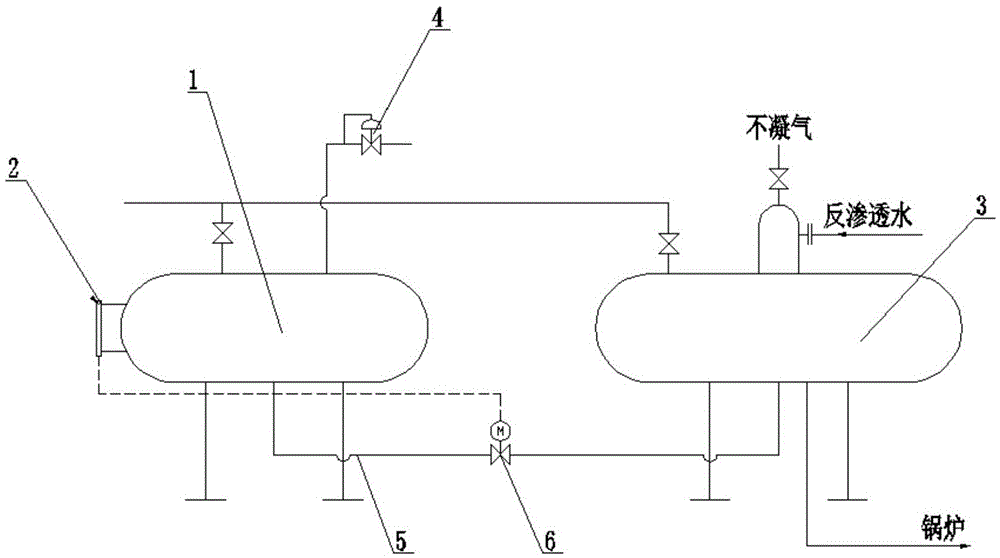

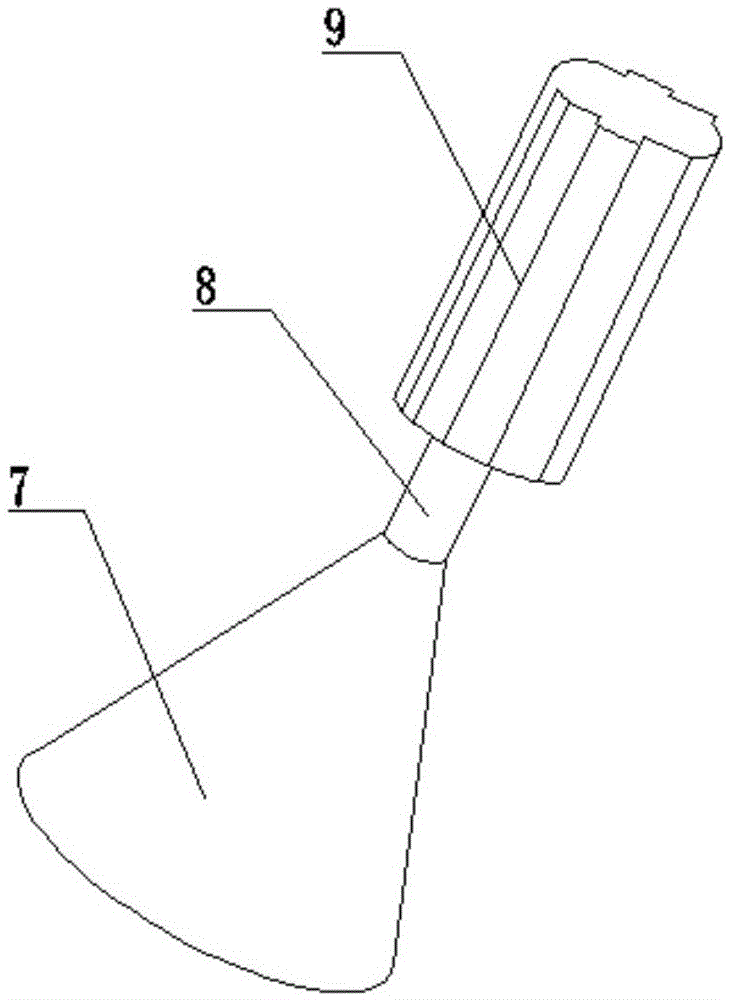

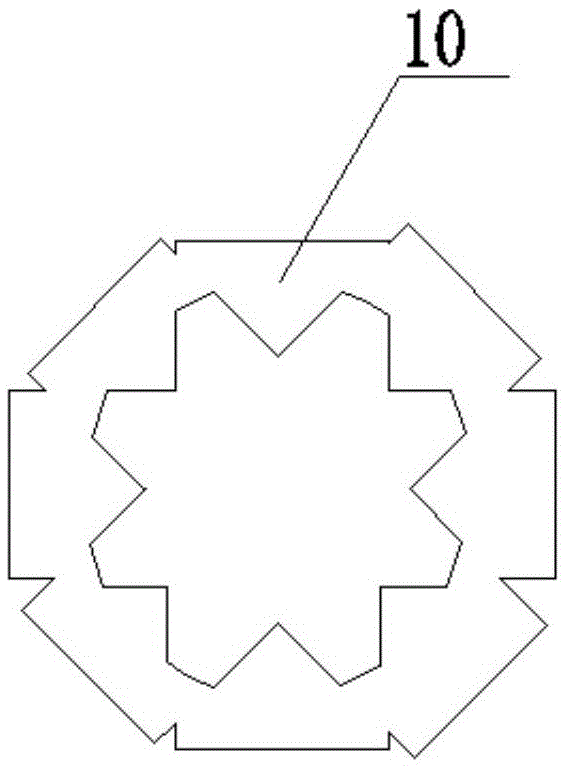

[0027] Such as figure 1 As shown, the condensation automatic water return system is characterized in that it includes a condensed water recovery tank 1, a deaerator 3 and a boiler, and the condensed water recovery tank 1 is connected to the boiler through a deaerator 3, and the deaerator 3 It includes a deaeration head and a water storage tank. The deaeration head is connected to the condensed water recovery tank 1 through a steam pipeline. The bottom of the water storage tank is provided with a communication pipe 5. The bottom of the condensed water recovery tank 1 and the deaerator 3 are connected through a communication pipe 5. An electric valve 6 is installed in the middle of the communication pipeline 5, and the electric valve 6 distributes the condensed water amount between the condensed water recovery tank 1 and the deaerator 3, so that the pressure of the condensed water r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com