Bamboo compound type board formed adopting injection molding and glue encapsulation and manufacturing process of bamboo compound type board

A technology of injection molding, encapsulation and composite molding, which is applied in synthetic resin layered products, layered products, metal layered products, etc., can solve the problems of insufficient plate molding ability, incomplete processing technology, and short service life, etc. To achieve the effect of convenient replacement operation, increased firmness, and simple connection method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

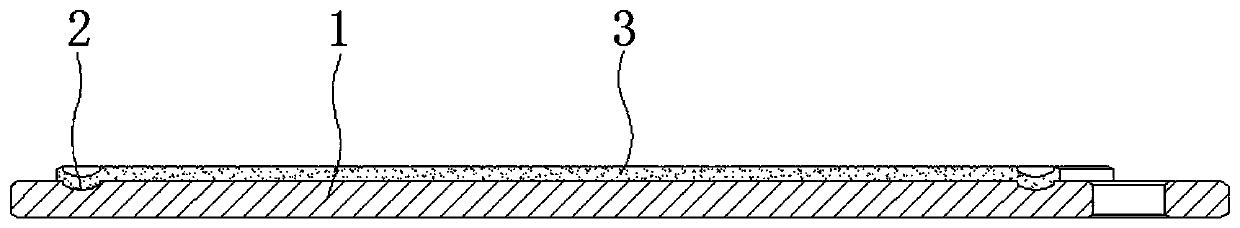

[0030] Fiber layer 301 described in embodiment 1, plastic layer 302, chaff layer 303 and valley fiber layer 304 constitute composite layer 3, the top of valley fiber layer 304 is provided with chaff layer 303, the top of described chaff layer 303 is provided with A plastic layer 302 , and a fiber layer 301 is arranged above the plastic layer 302 . This multi-material composite layer is more durable, and if one layer is worn out, the next layer can be removed.

Embodiment 2

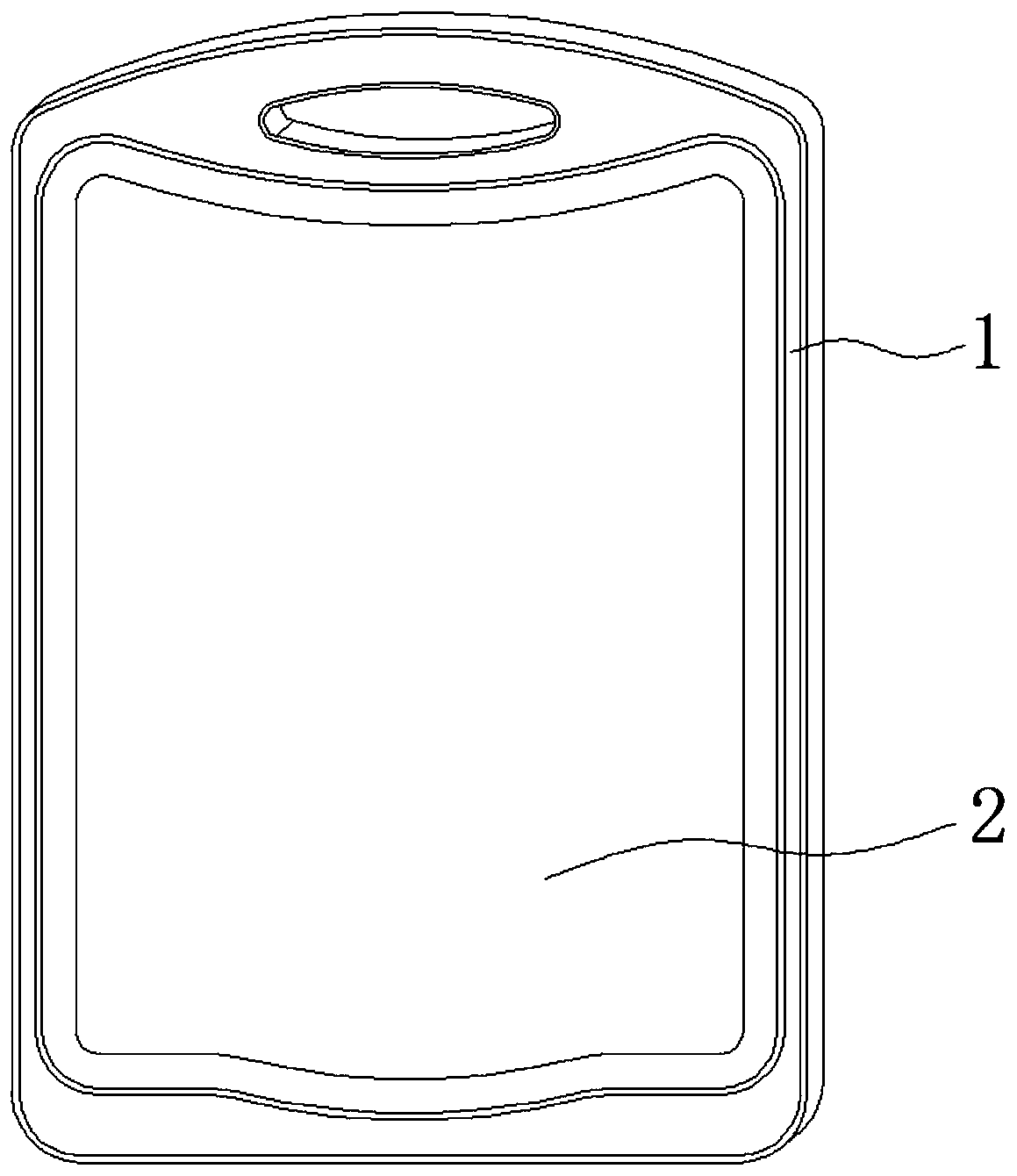

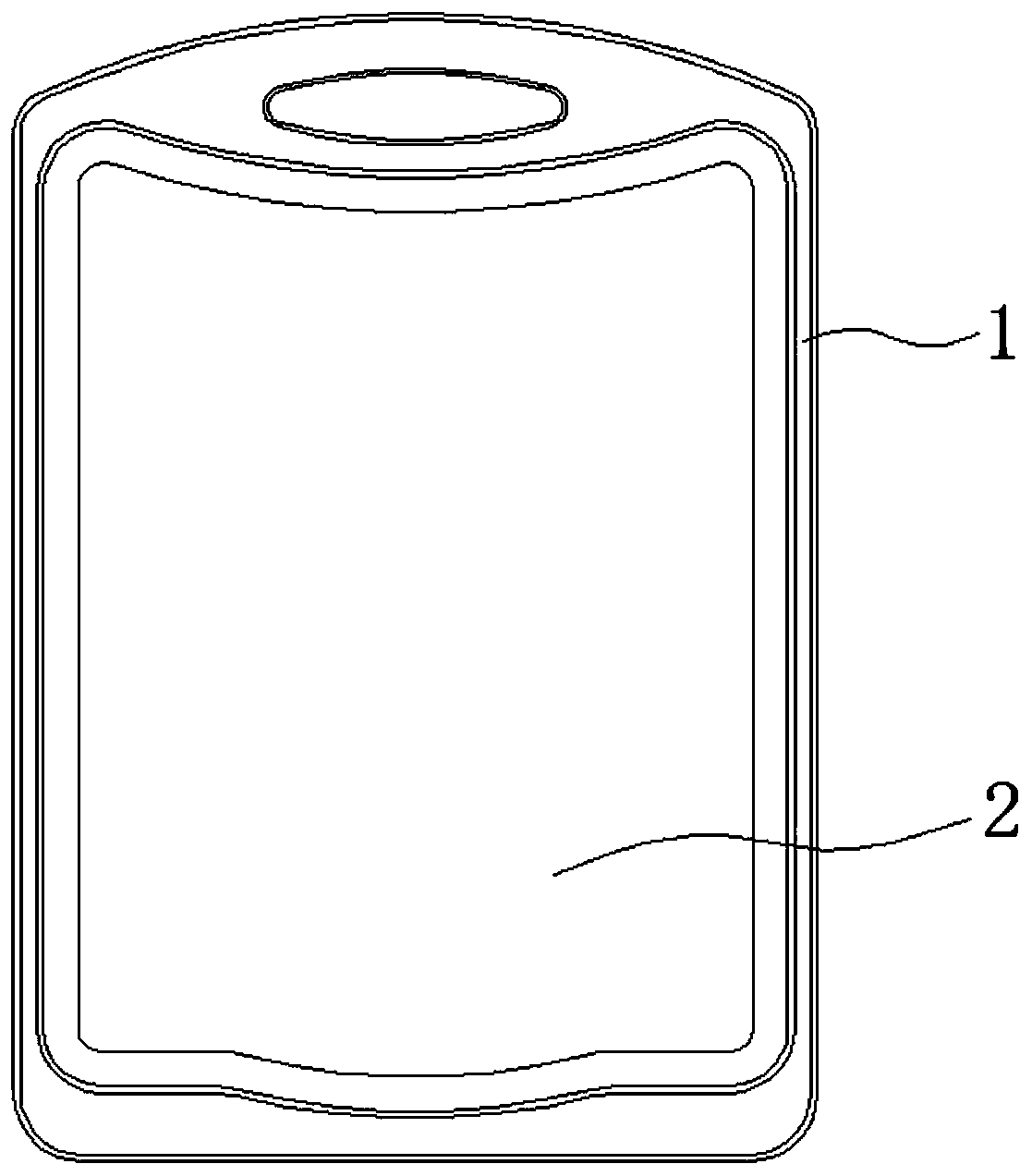

[0031] The central axis of the main body 1 in the second embodiment coincides with the central axis of the slot 2, and the width of the cross section of the slot 2 is 1 cm. This fixation is more firm.

Embodiment 3

[0032] The rear end surface of the composite layer 3 described in Example 3 is closely attached to the front surface of the whole bamboo board 1, and the composite layer 3 and the whole bamboo board 1 are bonded.

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com