Curved surface polishing machine for 3D concave polishing

A polishing machine and concave surface technology, which is applied in the field of curved surface polishing machines, can solve problems such as insufficient polishing, prolonged polishing processing time of workpieces, and insufficient polishing accuracy to meet the requirements. Effect of Polishing Efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

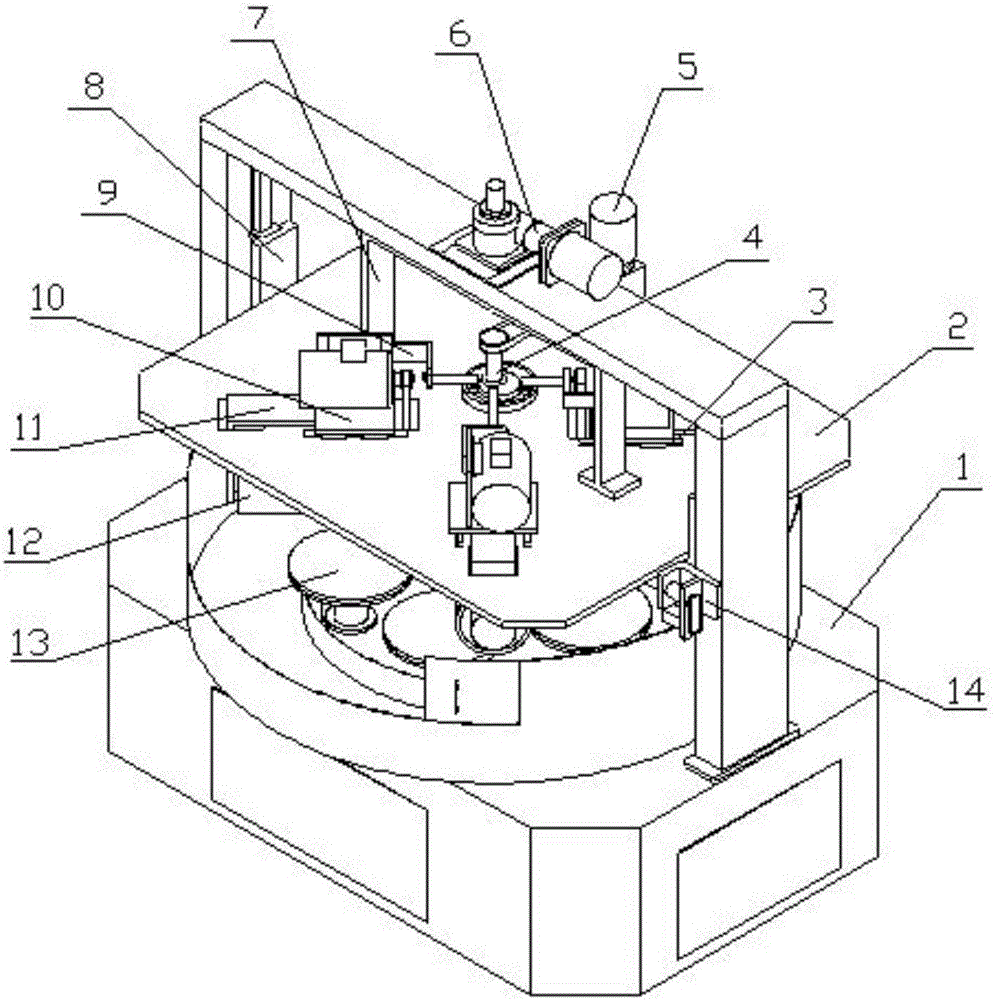

[0021] refer to figure 1 , this embodiment includes a box body part 1, an upper plate bottom plate 2, a linear slide rail I 3, a cam structure 4, a gear motor 5, a screw lifter 6, a lifting frame 7, a linear slide rail II 8, a connecting assembly 9, and a slide rail Mounting plate 10, support frame 11, polishing hair wheel 12 and transmission main body 13; said transmission main body 13 is installed in the box body part 1, and said transmission main body 13 is provided with rotary assembly, and said rotary assembly can do revolution motion Rotation movement is also possible, and the speed of revolution and rotation is adjustable; the linear slide rail II 8 is installed on the column of the box body part 1, the screw lifter 6 is installed on the beam of the box body part 1, and the wire The lower end of the rod lifter 6 is connected with the lifting frame 7, and the lifting frame 7 is connected with the upper plate bottom plate 2, the cam structure 4 and the linear slide rail I...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com