A method of 3D concave surface polishing

A 3D, concave technology, applied in the field of 3D concave polishing, can solve the problems of insufficient polishing, insufficient polishing accuracy, unstable product yield, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

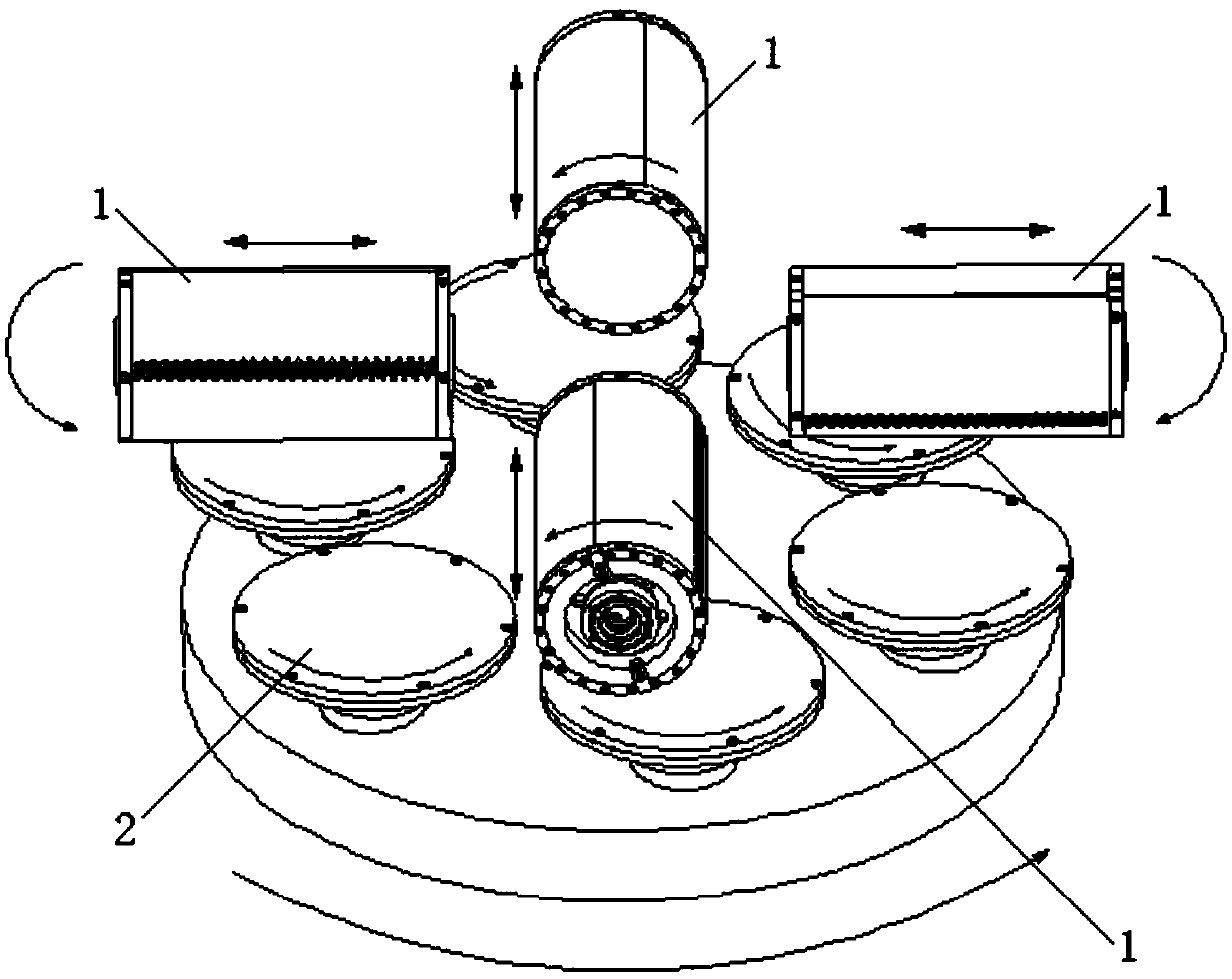

[0019] refer to figure 1 , a method for 3D concave surface polishing, using the rotation and reciprocating motion of the polishing hair wheel, and the rotation and revolution motion of the workpiece to effectively improve the polishing track of the 3D concave arc surface workpiece.

[0020] In this embodiment, the polishing hair wheel 1 drives the polishing hair wheel through an independent motor and a belt transmission mechanism to realize the rotation of the polishing hair wheel, and drives the cam to perform an eccentric circular motion through another motor and a belt transmission mechanism, and then drives the connecting assembly and the polishing hair The grinding wheel realizes the reciprocating motion of the polishing wheel; the workpiece is fixed by the vacuum adsorption of the tooling in the cutting disc 2, and rotates together with the cutting disc 2. The meshing transmission realizes the revolution.

[0021] In this embodiment, the connection assembly includes a c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com