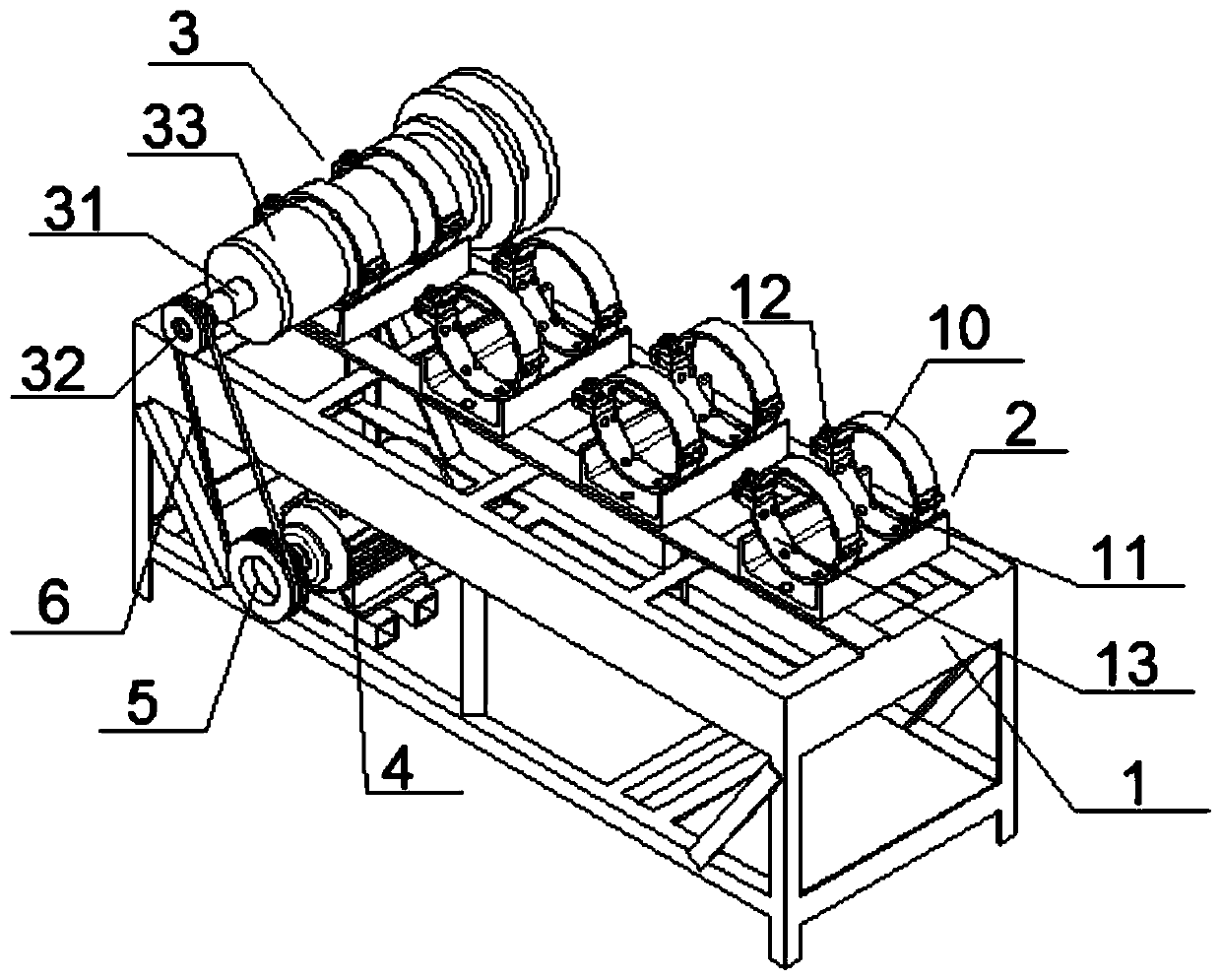

Mechanical main shaft test platform

A test platform and test platform technology, applied in metal processing machinery parts, measuring devices, measuring/indicating equipment, etc., can solve problems such as inability to measure multiple spindles and low work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

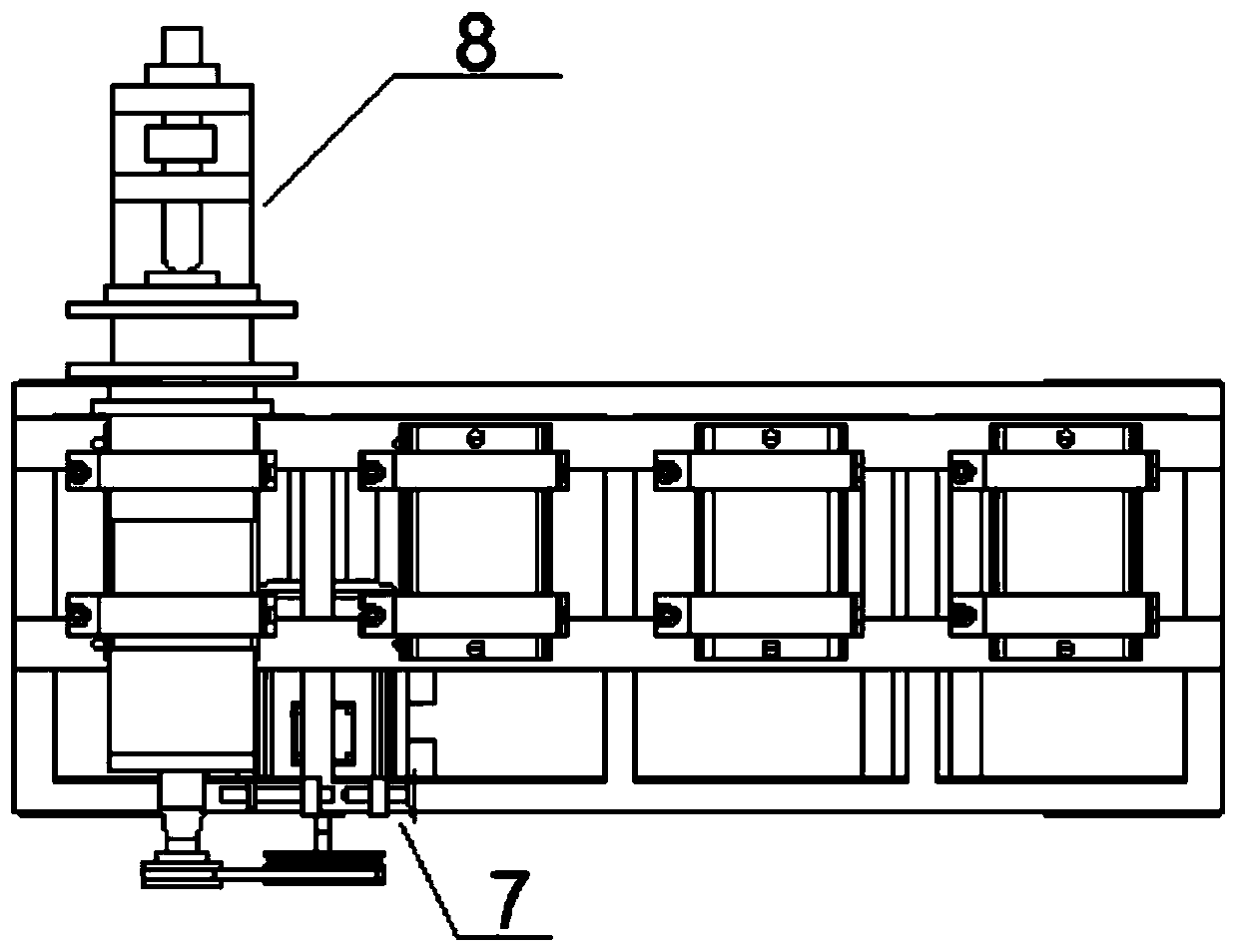

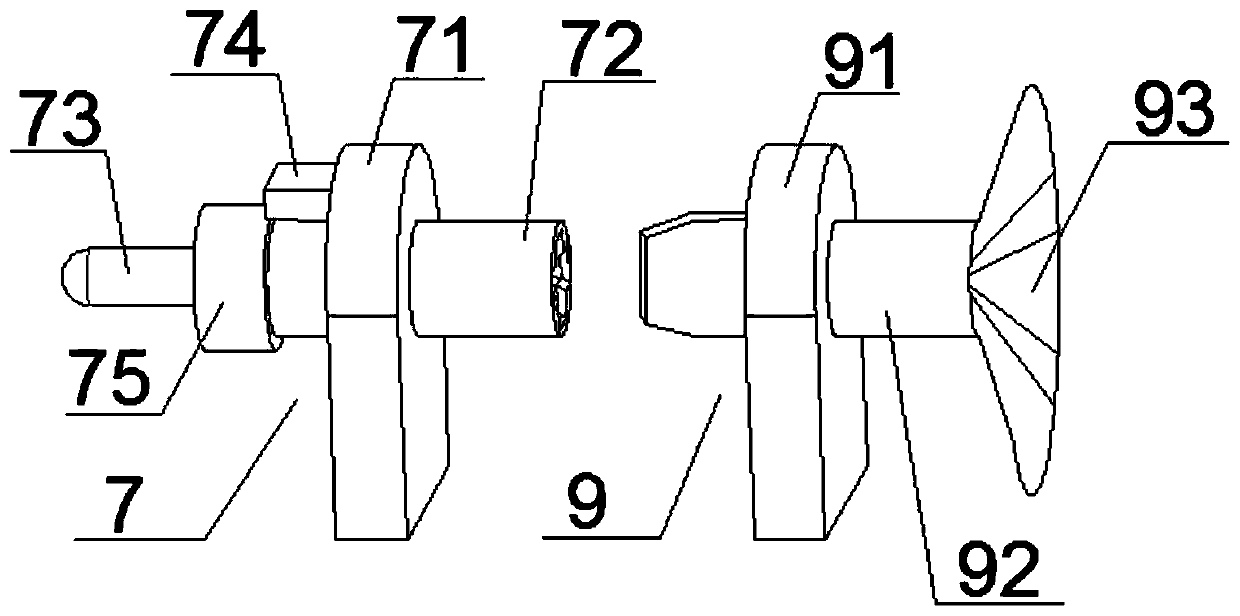

[0028] The technical solution of the present invention will be further described in detail below in conjunction with the accompanying drawings, but the protection scope of the present invention is not limited to the following description.

[0029] As the processing execution part of the machine tool, the spindle is the most important part of the machine tool. The mechanical spindle is one of the most commonly used spindle types at present. The mechanical spindle will produce axial movement and radial runout during operation, and the axial movement and radial runout will also affect the parts. Machining accuracy, secondly, when multiple spindles are needed, it is necessary to simulate the working state of multiple spindles, while in the prior art, when testing multiple spindles, it is necessary to test each spindle one by one, which increases the man-hours of testing and causes The efficiency is low, and at the same time, there is no test bench in the existing technology that c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com