A method for processing nickel-cobalt hydroxide

A technology of nickel-cobalt hydroxide and hydrogen peroxide solution, applied in the direction of cobalt sulfate, nickel sulfate, process efficiency improvement, etc., can solve the problems of nickel precipitation, reducing nickel recovery rate, affecting the quality of ternary precursor products, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

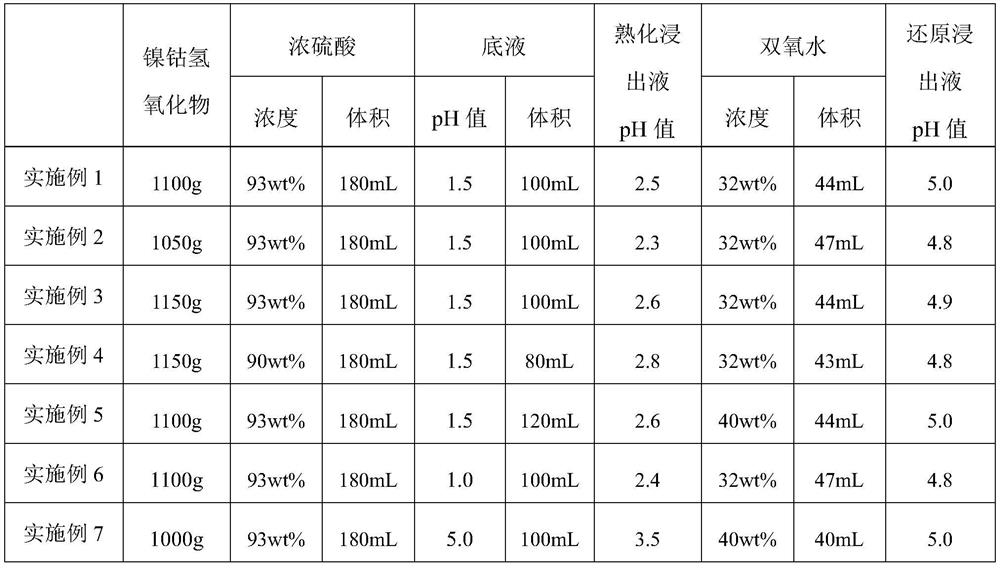

Embodiment 1

[0051] Take 100mL of nickel sulfate solution with a pH value of 1.5 as the bottom solution, add 180mL of industrial concentrated sulfuric acid with a mass concentration of 93%, and then put it in a hot water bath at 80°C (for heat preservation, not heating) and stir; add 1100g of nickel Cobalt hydroxide is matured and leached in a high-acid environment, and the reaction time is 1.5 hours to obtain a mature leachate, pH=2.5; then add analytically pure hydrogen peroxide with a mass concentration of 32% for reduction leaching, adjust the pH value, and react for 1.5 hours Dilute with water to obtain a reducing leach solution with pH=5.0; filter to obtain a filter cake containing iron, aluminum, silicon and manganese impurities and a nickel-cobalt sulfate filtrate.

Embodiment 2

[0053] Take 100mL of nickel sulfate solution with a pH value of 1.5 as the bottom solution, add 180mL of industrial concentrated sulfuric acid with a mass concentration of 93%, and then put it in a hot water bath at 80°C (for heat preservation, not heating) and stir; add 1050g of nickel Cobalt hydroxide is matured and leached in a high-acid environment, and the reaction time is 1.5 hours to obtain a mature leachate, pH=2.3; then add analytically pure hydrogen peroxide with a mass concentration of 32% for reduction leaching, adjust the pH value, and react for 1.5 hours Dilute with water to obtain a reducing leach solution with pH=4.8; filter to obtain a filter cake containing iron, aluminum, silicon and manganese impurities and a nickel-cobalt sulfate filtrate.

Embodiment 3

[0055] Take 100mL of nickel sulfate solution with a pH value of 1.5 as the bottom solution, add 180mL of industrial concentrated sulfuric acid with a mass concentration of 93%, and then put it in a hot water bath at 80°C (for heat preservation, not heating) and stir; add 1150g of nickel Cobalt hydroxide was matured and leached in a high-acid environment, and the reaction time was 1.5 hours to obtain a mature leachate, pH = 2.6; then add analytically pure hydrogen peroxide with a mass concentration of 32% for reduction leaching, adjust the pH value, and react for 1.5 hours Dilute with water to obtain a reducing leach solution with pH=4.9; filter to obtain a filter cake containing iron, aluminum, silicon and manganese impurities and a nickel-cobalt sulfate filtrate.

PUM

| Property | Measurement | Unit |

|---|---|---|

| chemical oxygen demand (mass) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com