Nuclear-shell-type catalyst, synthesis method thereof, and method for preparing gamma-valerolactone through catalyzing of levulinic acid by nuclear-shell-type catalyst

A technology of levulinic acid and catalyst, which is applied in the field of preparing γ-valerolactone by hydrogenation of levulinic acid, can solve the problems of poor catalyst stability, poor catalyst reuse performance, easy agglomeration and loss of active material metals, and prevents sintering. or bleed, optimum conversion and selectivity, inhibition of sintering and bleed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

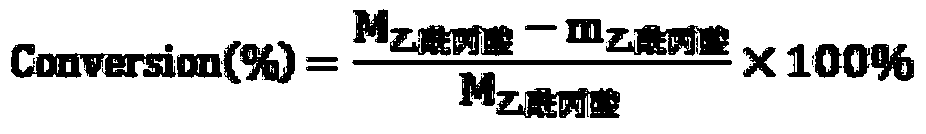

Method used

Image

Examples

Embodiment 1

[0030] Example 1 Core-shell catalyst Pd@mSiO 2 One-pot synthetic method for

[0031] S 1 1. Mix 0.12g CTAB and 45mL deionized water in a 150mL three-necked flask, stir and heat at room temperature to 80°C, and keep it for 30min, then add 5mL 0.02mol / L K 2 PdCl 4 solution, after continuing to stir for 10min, the solution changed from colorless and transparent to orange-red, and NaBH was added dropwise 4 Aqueous solution, continue to stir for 30min, obtain metal Pd colloidal solution;

[0032] S 2 1. Add 0.5mol / L NaOH solution to the metal Pd colloidal solution, adjust the pH value of the solution to 10, then dropwise add 0.2mLTEOS and 1.8mL methanol mixed solution to initiate the polymerization reaction of silica gel, and centrifuge to obtain Pd@SiO 2 product and dried overnight at 60 °C;

[0033] S 3 , the dried Pd@SiO 2 Roasting in a muffle furnace, the temperature was raised to 500°C at a rate of 5°C / min during firing, and the firing time at 500°C was 6h, and then 60...

Embodiment 2

[0036] Example 2 Core-shell catalyst Rh@mSiO 2 One-pot synthetic method for

[0037] S 1 , Mix 0.12g CTAB and 45mL deionized water in a 150mL three-neck flask, stir and heat at room temperature to 80°C, and keep it for 30min, then add 5mL0.02mol / L Na 2 RhCl 4 solution, after continuing to stir for 10min, the solution changed from colorless and transparent to orange-red, and NaBH was added dropwise 4 Aqueous solution, continue to stir for 30min, obtain metallic Rh colloidal solution;

[0038] S 2 1. Add 0.5mol / L NaOH solution to the metallic Rh colloidal solution, adjust the pH value of the solution to 11, then dropwise add a mixed solution of 0.2mLTEOS and 1.8mL methanol to initiate the polymerization reaction of silica gel, and centrifuge to obtain Rh@SiO 2 product and dried overnight at 60 °C;

[0039] S 3 , the dried Rh@SiO 2 Roasting in a muffle furnace, the temperature was raised to 500°C at a rate of 5°C / min during firing, and the firing time at 500°C was 6h, and...

Embodiment 3

[0040] Example 3 Core-shell catalyst Pt@mSiO 2 One-pot synthetic method for

[0041] S 1 1. Mix 0.12g CTAB and 45mL deionized water in a 150mL three-neck flask, stir and heat at room temperature to 80°C, and keep it for 30min, then add 5mL0.02mol / L K 2 PtCl 4 solution, after continuing to stir for 10min, the solution changed from colorless and transparent to orange-red, and NaBH was added dropwise 4 Aqueous solution, continue to stir for 30min, obtain metal Pt colloidal solution;

[0042] S 2 1. Add 0.5mol / L NaOH solution to the metal Pt colloidal solution, adjust the pH value of the solution to 10, then dropwise add 0.2mLTEOS and 1.8mL methanol mixed solution to initiate the polymerization reaction of silica gel, and centrifuge to obtain Pt@SiO 2 product and dried overnight at 60 °C;

[0043] S 3 , the dried Pt@SiO 2 Roasting in a muffle furnace, the temperature was raised to 500°C at a rate of 5°C / min during firing, and the firing time at 500°C was 6h, and then 60mL / ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com