CO2 adsorbent and preparation method thereof

A technology of adsorbent and molding aid, which is applied in the field of CO2 adsorbent and its preparation, can solve the problem of low adsorption capacity, achieve good stability and chemical stability, high practicability, and improve the effect of adsorption capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

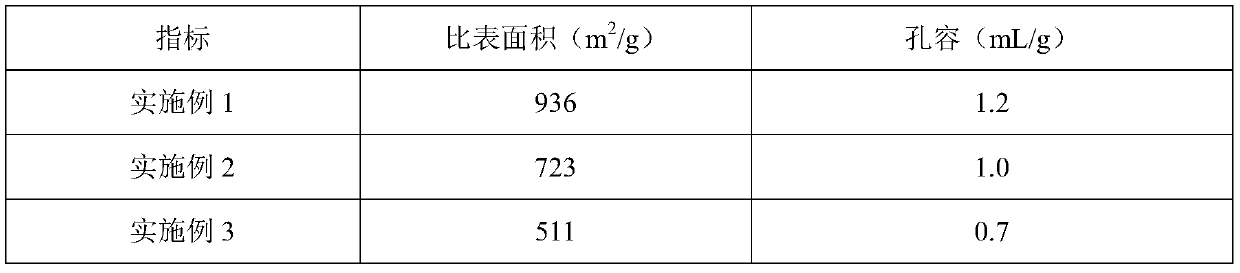

Embodiment 1

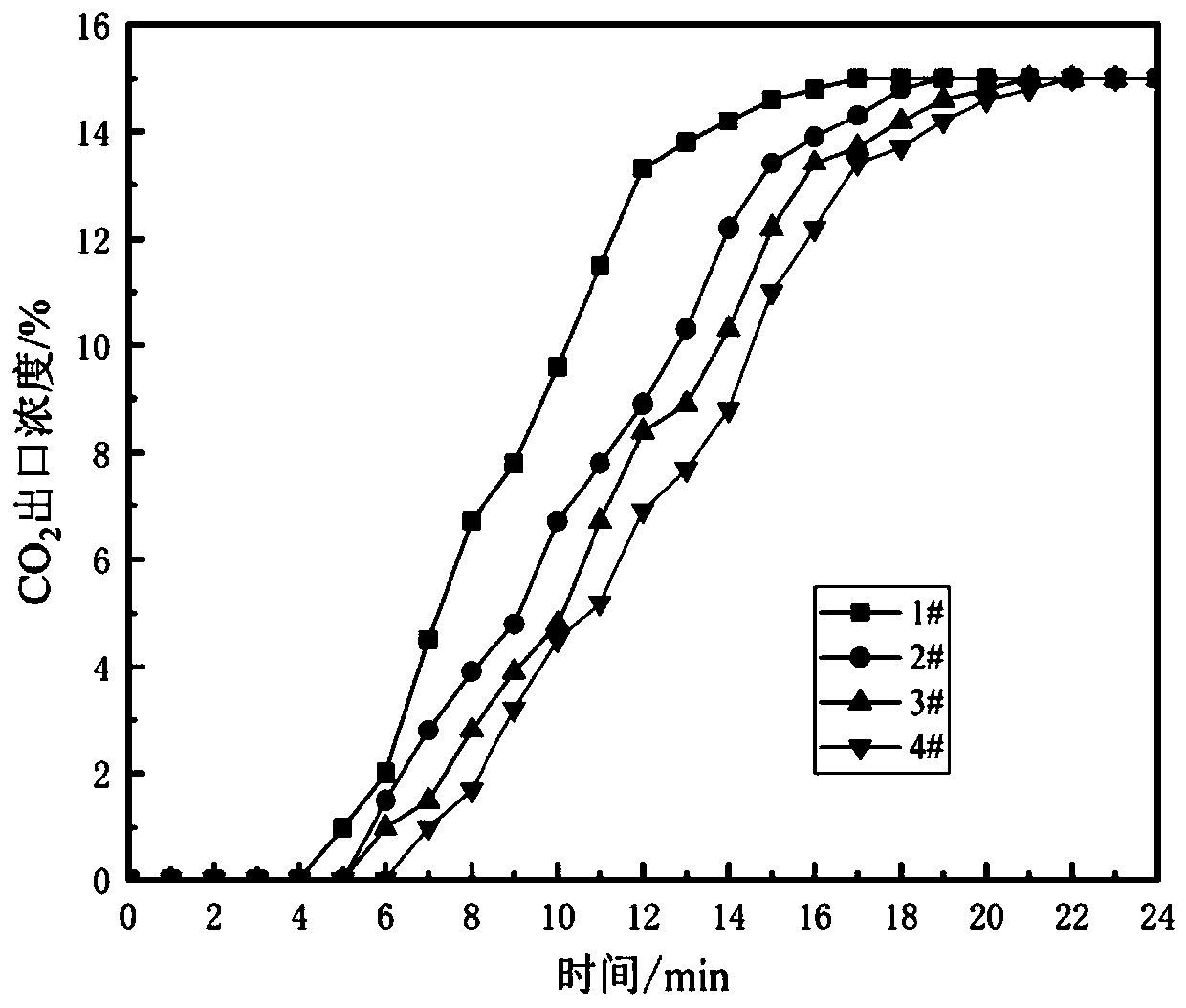

[0069] This embodiment provides a CO 2 Adsorbent and preparation method thereof, the preparation method comprises the following steps:

[0070] 1. Preparation of adsorbent carrier

[0071] 1) Preparation of MIL-101 metal organic framework: 50mL of deionized water, 4.00g of chromium nitrate nonahydrate, 3.00g of terephthalic acid, and 1.00g of hydrofluoric acid were mixed and charged into a polytetrafluoroethylene-lined autoclave, Crystallize at 200°C for 12h. The obtained suspension was washed twice with hot deionized water, dimethylformamide (DMF) and 95% ethanol respectively, dried in an oven at 120 °C for 16 h, and the obtained sample was mixed with 240 mL of ethanol and put into an autoclave, After activation at 80°C for 36h, the precipitated samples were centrifuged and dried in an oven at 120°C for 16h. The obtained sample was mixed with 300 mL of ammonium fluoride aqueous solution with a concentration of 1 mol / L, and then loaded into an autoclave, activated at 50 °C ...

Embodiment 2

[0079] This embodiment provides a CO 2 Adsorbent and preparation method thereof, the preparation method comprises the following steps:

[0080] 1. Preparation of adsorbent carrier

[0081] 1) Preparation of MIL-101 metal organic framework: 70mL of deionized water, 6.00g of chromium nitrate nonahydrate, 1.00g of terephthalic acid, and 0.20g of hydrofluoric acid were mixed and charged into a polytetrafluoroethylene-lined autoclave, Crystallize at 250°C for 6h. The obtained suspension was washed twice with hot deionized water, dimethylformamide (DMF) and 95% ethanol respectively, dried in an oven at 160 °C for 8 h, and the obtained sample was mixed with 240 mL of ethanol and placed in an autoclave, After activation at 120°C for 12h, the precipitated samples were centrifuged and dried in an oven at 160°C for 8h. The obtained sample was mixed with 300 mL of ammonium fluoride aqueous solution with a concentration of 3 mol / L, and then loaded into an autoclave, activated at 80 °C f...

Embodiment 3

[0089] This embodiment provides a CO 2 Adsorbent and preparation method thereof, the preparation method comprises the following steps:

[0090] 1. Preparation of adsorbent carrier

[0091] 1) Preparation of MIL-101 metal organic framework: 55mL of deionized water, 5.50g of chromium nitrate nonahydrate, 2.00g of terephthalic acid, and 0.50g of hydrofluoric acid were mixed and charged into a polytetrafluoroethylene-lined autoclave, Crystallize at 210°C for 10h. The obtained suspension was washed twice with hot deionized water, dimethylformamide (DMF) and 95% ethanol respectively, dried in an oven at 140 °C for 10 h, and the obtained sample was mixed with 240 mL of ethanol and placed in an autoclave, After activation at 110°C for 18h, the precipitated samples were centrifuged and dried in an oven at 140°C for 10h. The obtained sample was mixed with 300 mL of ammonium fluoride aqueous solution with a concentration of 2 mol / L, and then loaded into an autoclave, activated at 70 °...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com