High-strength fiber reinforced composite material connecting piece and formula and manufacturing process thereof

A technology of reinforced composite materials and high-strength fibers, applied in the direction of coating, etc., can solve the problems of easy breakage of connectors, poor pullout ability, poor heat insulation performance, etc., to enhance the pullout force, reduce the possibility of breaking free, and prevent The effect of improving the combustion performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

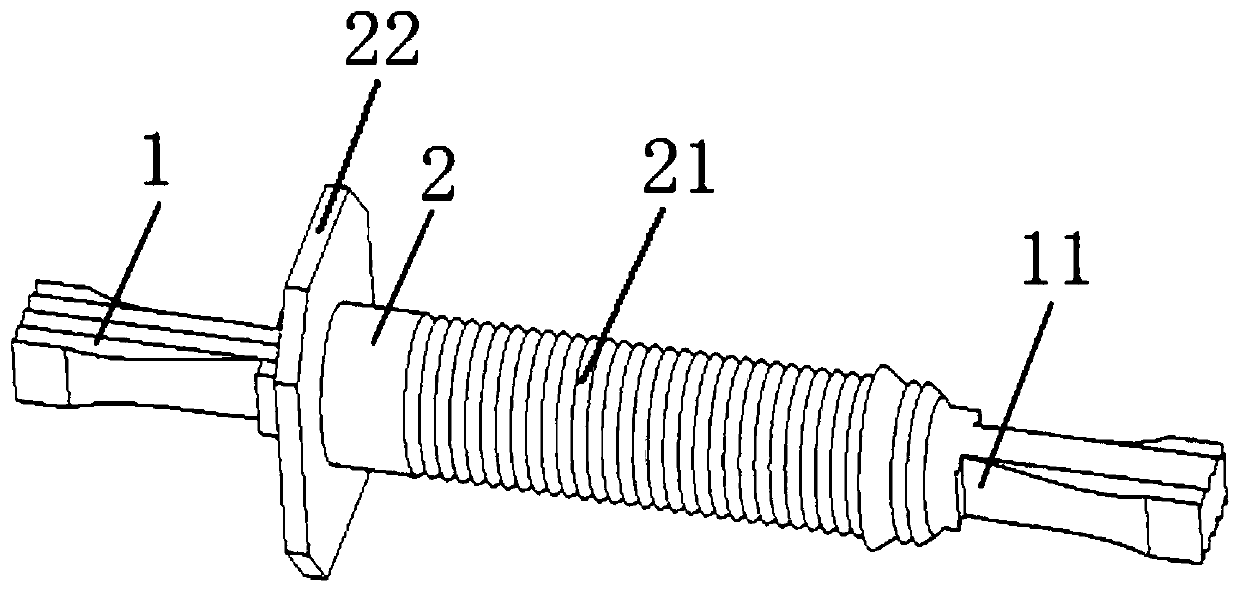

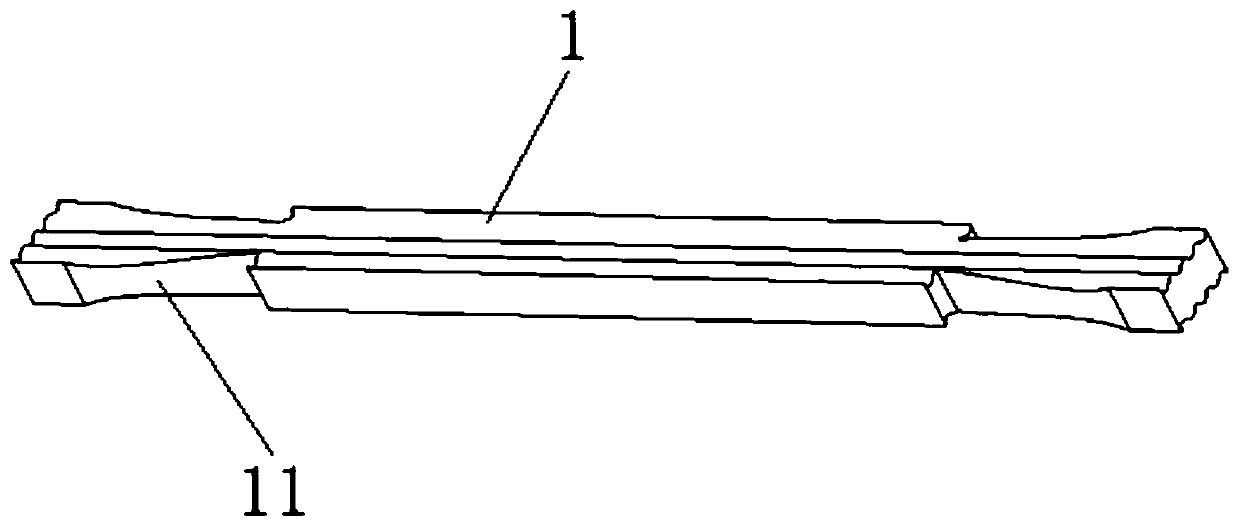

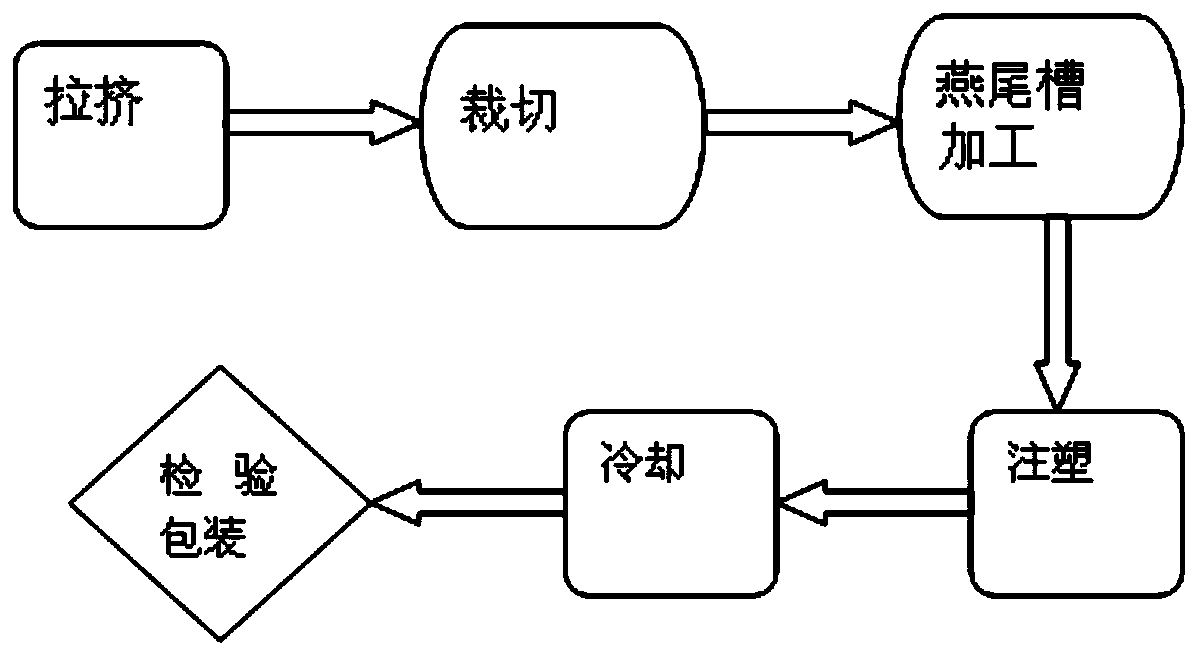

[0045] The high-strength fiber-reinforced composite material connector in this embodiment includes an anchoring fiber rod 1 and an injection-molded intermediate body 2. The anchoring fiber rod 1 is in the shape of a flat strip, and its cut surface is wavy, such as figure 2 As shown, since the top surface and the bottom surface of the anchoring fiber rod 1 are not flat, they are all set as wavy surfaces, so the cut surface has a wavy shape. Of course, the two sides of the anchoring fiber rod 1 can also be set as wavy surfaces, so that the four sides of the cut surface will all be wavy. The anchoring fiber rod 1 is also provided with two symmetrical dovetail grooves 11 at the ends of two opposite sides. The anchoring fiber rod 1 is designed to have a wave surface and a dovetail groove 11, which can greatly increase the contact surface between the anchoring fiber rod 1 and the cement, increase friction and fastening force, and the special-shaped surface can bring stronger anchor...

Embodiment 2

[0058] The injection molding intermediate 2 of this embodiment has the same structure as that of the injection molding intermediate 2 of Embodiment 1, except that the anchoring fiber rod 1 of this embodiment is cylindrical or elliptical, and its cut surface is petal-shaped or five-pointed star-shaped. Since the surface of the anchoring fiber rod 1 is not a smooth curved surface, but has protrusions and depressions, its cutting surface is petal-shaped or five-pointed star-shaped. Moreover, a number of lock grooves 12 are uniformly arranged on the axial surface thereof.

[0059] The formulation of the anchoring fiber rod and the injection molding intermediate in this embodiment are the same as in Embodiment 1, but the manufacturing process of the connecting piece is different. The process steps of this embodiment are:

[0060] S1. Preforming: Using preforming equipment, the resin-impregnated fiber yarn is preformed into splines with petal-shaped or five-pointed star-shaped cutti...

Embodiment 3

[0069] The difference between this example and Example 1 and Example 2 is that the formulation of the anchoring fiber rod can also be composed of the following components and mass ratio: 60 parts of fiber, 15 parts of resin, 5 parts of active reinforcing filler, solidified 3 parts of agent, 2 parts of toughening agent.

[0070] Wherein, the fiber is selected from glass fiber; the resin is selected from vinyl resin or epoxy resin, the active reinforcing filler can be selected from aluminum hydroxide or calcium carbonate or talcum powder or quartz powder, etc., and the curing agent can be selected from PBO curing Paste, tert-butyl ester, etc., PE powder, etc. can be selected as the toughening agent.

[0071] The formulation of the injection molding intermediate in this embodiment can also be composed of the following components and mass ratio: 75 parts of plastic, 8 parts of activated filler, and 8 parts of fiber. Wherein, the plastic can be any one of PP, ABS, PVC, etc., the a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| mechanical properties | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com