Pesticide mixing device for extruding and flow pushing for agriculture

A mixing device and agricultural technology, which is applied in the field of agriculture, can solve the problems of mixing four corners and uneven mixing of medicines, and achieve the effects of avoiding dead corners of stirring, easy dispersion, and improving fluidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

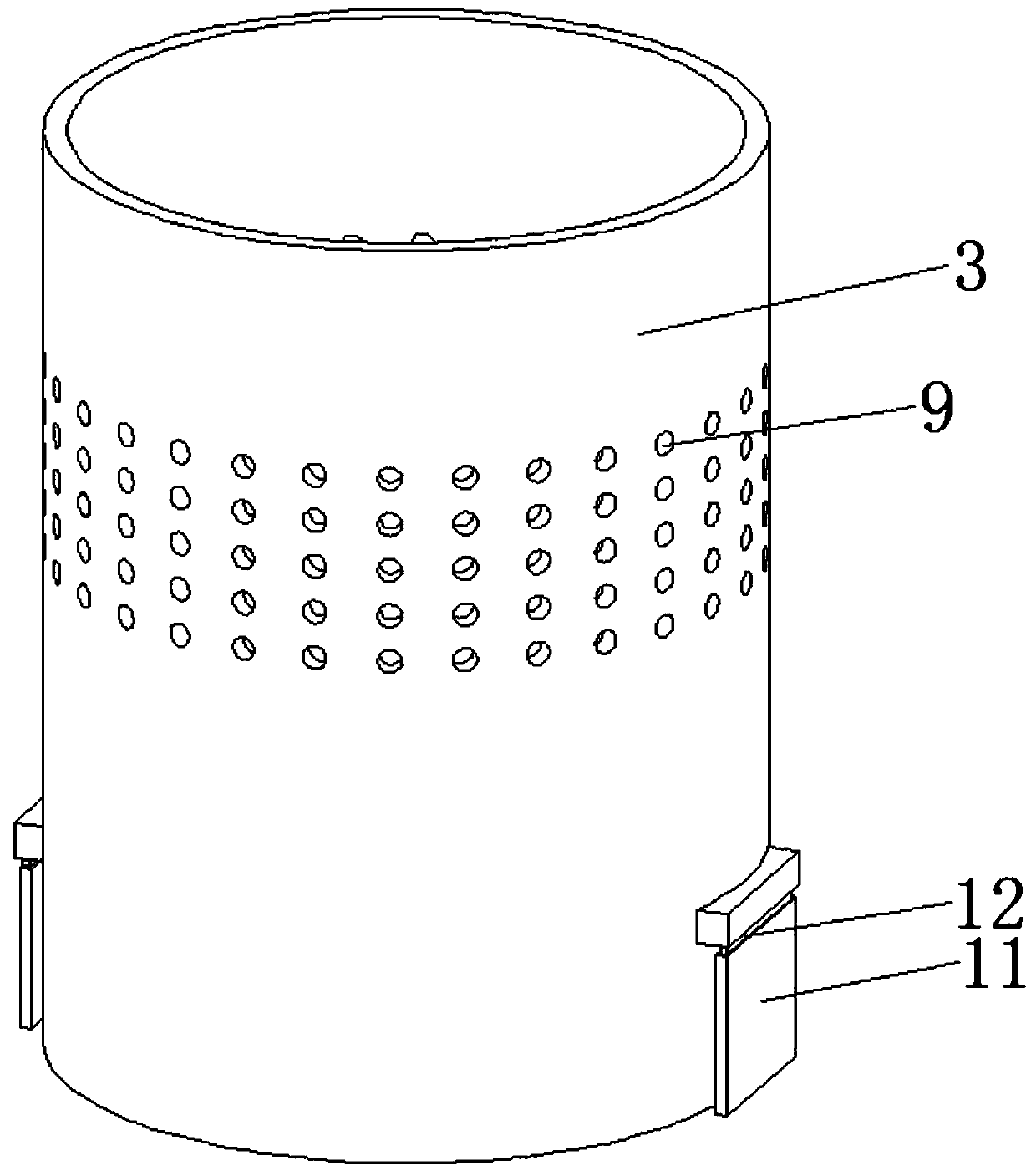

[0022] Please refer to the figure, in the embodiment of the present invention, an agricultural extrusion push-flow medicament mixing device includes a housing 1, a base 2, a feed hopper 4 and a discharge pipe 22; the base 2 is fixedly installed on the housing 1 The bottom of the feed hopper 4 is communicated with the top of the housing 1, and the bottom of the feed hopper 4 communicates with the inclined guide pipe 21 extending into the housing 1, and the medicine filled from the feed hopper 4 along the The guide pipe 21 enters the housing 1, and the water supply pipe 20 is connected to the side wall of the feed hopper 4, and the water supply pipe 20 communicates with the water supply main pipe through the flange, and the mixed water is passed into the interior; the bottom of the housing 1 A discharge pipe 22 with a valve is connected to discharge the mixed liquid from the casing 1 .

[0023] The housing 1 is coaxially fixed with a vertical extrusion push tube 3 with an upward...

Embodiment 2

[0026] On the basis of Embodiment 1, a horizontal rotating plate 14 is arranged on the outer side of the extruding push flow tube 3, and a plurality of vertical stirring rods 23 are uniformly fixed on the lower side of the rotating plate 14, and the stirring rods 23 A scraper 24 is fixed on the lower end, and the scraper 24 can stir the liquid medicine at the bottom of the housing 1 during the moving process to improve the mixing effect; The inner ring of the outer bearing 19 is fixed on the extrusion push flow tube 3, and the outer bearing 19 is fixedly installed on the outer wall of the rotating plate 14. The rotating plate 14 is supported so that it rotates stably in the horizontal direction. On the upper surface of the rotating plate 14, an upward gear ring 15 is fixed. The gear ring 15 is meshed with a gear 16. On the output shaft, the gear 16 is driven to rotate by the driving motor 17 to realize the rotation of the rotary plate 14 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com