Whitening and moisturizing alginate facial mask and preparation method thereof

A technology of alginate ester and alginic acid, which is applied in the field of whitening and moisturizing alginate mask and its preparation, can solve the problems of non-woven fabric dissolution, non-recyclability, consumer allergy, etc., and achieve the improvement of esterification grafting efficiency and enhancement The effect of water retention performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

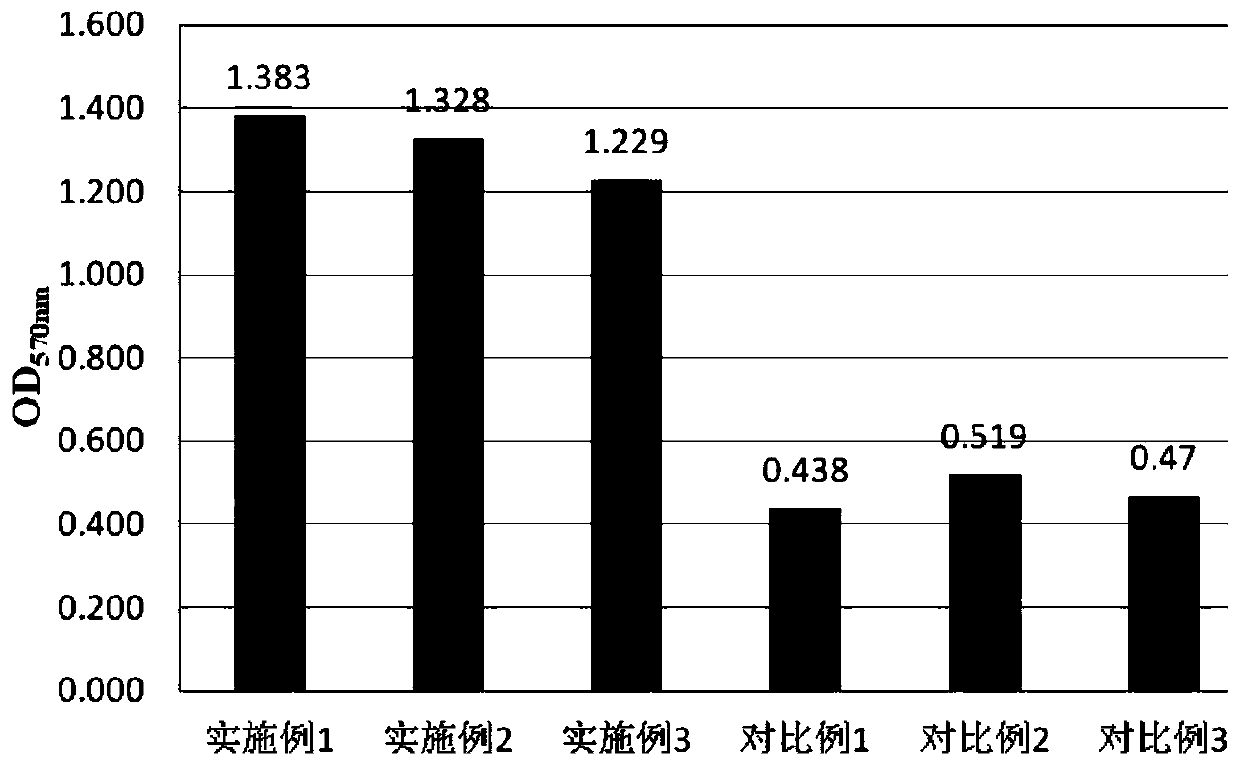

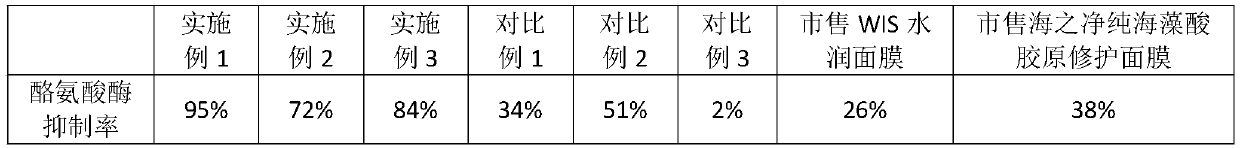

Examples

preparation example Construction

[0026] The invention provides a preparation method of whitening and moisturizing alginate facial mask, which comprises the following steps:

[0027] S1: Synthesis of alginic acid chloride: Dispersing and dissolving alginic acid powder in CCl 4 Solution, obtain alginic acid solution, add PCl dropwise in described alginic acid solution 3 , control the temperature at 50-55°C, react for 4-8 hours, then raise the temperature to 60-70°C, and react for 1-1.5 hours to obtain alginate chloride;

[0028] S2: Synthesis of ternary compound alginate: disperse and dissolve octacosanol, kojic acid, and arbutin in a solvent to obtain a mixed solution, add dropwise the alginic acid chloride prepared in step S1 to the mixed solution, and store at room temperature The following reaction, to get ternary compound alginate;

[0029] S3: Preparation of alginate mask: completely dissolve the ternary compound alginate prepared in step S2 in acetone solution, stir evenly to obtain a spinning solution...

Embodiment 1

[0043] S1: The alginic acid powder is subjected to plasma treatment, the conditions are: the gas uses oxygen, the treatment power is 280W, the pressure is 55Pa, and the treatment time is 12min; 1.5g of the plasma-treated alginic acid powder is added to the three-necked flask, and 100ml of CCl 4 Dispersed and dissolved, 12g PCl 3 Use a dropping funnel to slowly drop into a three-necked flask, the reaction temperature is 55°C, the reaction time is 6h, then the temperature is raised to 60°C, and the reaction is continued for 1h, and the reaction is stopped to obtain alginate chloride;

[0044] S2: Add 0.8g of octacosanol, 0.4g of kojic acid, and 0.2g of arbutin into a three-necked flask, disperse and dissolve them with 40ml of acetone and 8ml of pyridine solution, and then slowly drop 15ml of alginate chloride into In a three-necked flask, react at room temperature. After reacting for 4 hours, the product obtained by the reaction was washed with an appropriate amount of ice etha...

Embodiment 2

[0047] S1: The alginic acid powder is subjected to plasma treatment, the conditions are: the gas is nitrogen, the treatment power is 250W, the pressure is 50Pa, and the treatment time is 10min; 4 Dispersed and dissolved, 2.5g PCl 3 Use a dropping funnel to slowly drop into a three-necked flask, the reaction temperature is 55°C, the reaction time is 4h, then the temperature is raised to 60°C, and the reaction is continued for 1h, and the reaction is stopped to obtain seaweed chloride;

[0048] S2: Add 0.5g of octacosanol, 0.2g of kojic acid, and 0.1g of arbutin into a three-necked flask, disperse and dissolve it with 20ml of acetone and 5ml of pyridine solution, and then slowly drop 8ml of alginate chloride into it with a dropping funnel In a three-necked flask, react at room temperature. After reacting for 2 hours, the product was washed with an appropriate amount of ice ethanol, suction-filtered on a Buchner funnel, washed repeatedly for at least 3 times, and dried to obtain...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com