Rub-resisting anti-pilling pure wool yarn and processing technology thereof

A processing technology, anti-pilling technology, applied in the direction of yarn, wear-resistant fiber, biochemical fiber treatment, etc., can solve the problems of easy hair loss, reduced comfort, and high yarn curling degree, and achieve enhanced friction resistance performance, The effect of good purity requirements and high tensile strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

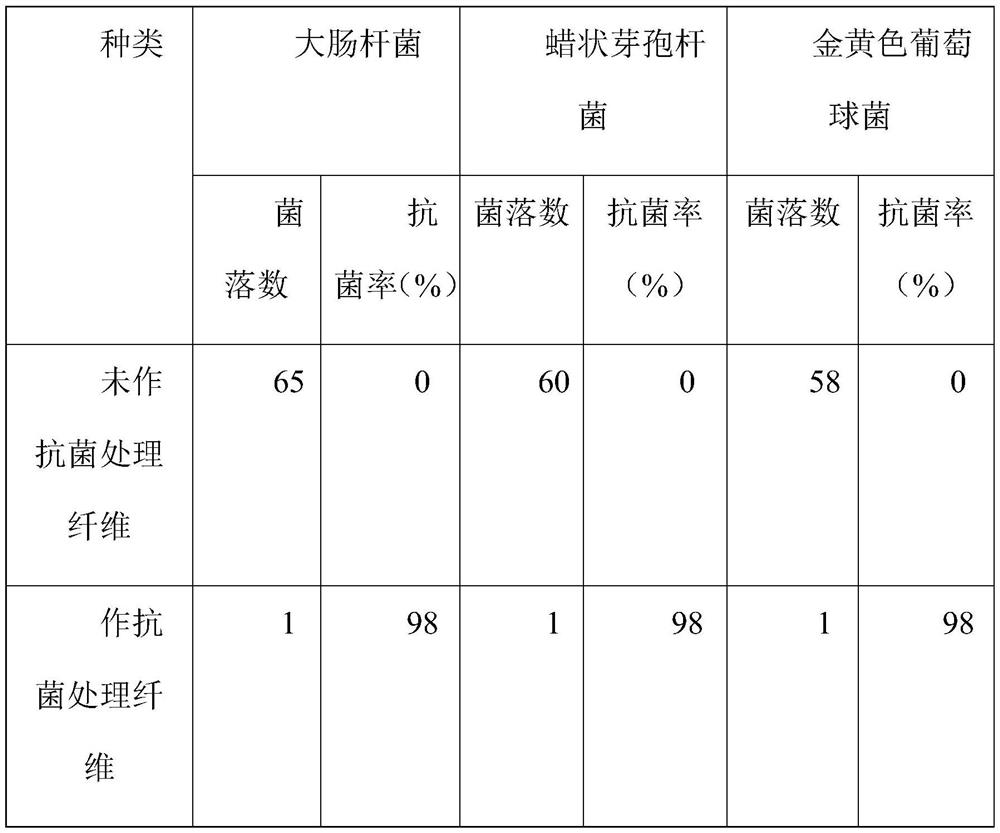

[0036] A kind of anti-friction and anti-pilling pure wool yarn, the pure wool yarn is a single yarn or a ply yarn spun from several wool fibers, the wool fibers are ultra-fine wool fibers, and the ultra-fine wool fibers are treated with antibacterial and antibacterial agents. Antibacterial wool fiber and antistatic wool fiber are formed after electrostatic agent treatment, and described pure wool yarn comprises mass parts 20 parts of antibacterial wool fibers, 30 parts of antistatic wool fibers, 20 parts of original superfine wool fibers, and the surface of described pure wool yarn is coated with Has a silicone coating.

[0037] The ply count of the pure wool yarn is a single yarn count of 160 and a ply yarn count of 180 / 3. The average diameter of the superfine wool fibers is 14.5 μm, the fineness is 85 s, and the length is 90 mm. The average linear density of the superfine wool fiber is 0.05dtex.

[0038] The above-mentioned pure wool yarn is made by the following processin...

Embodiment 2

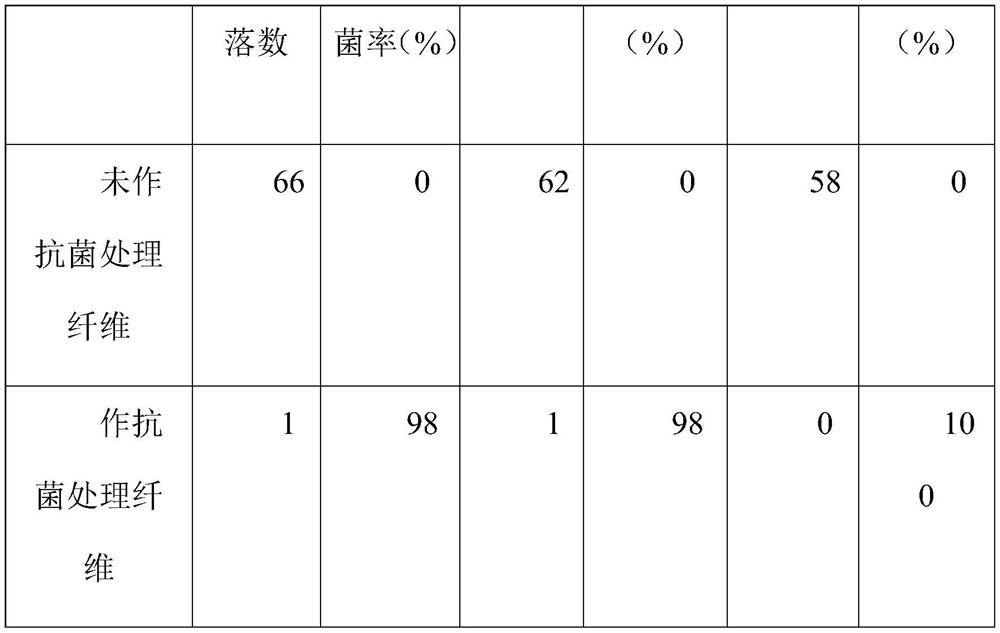

[0058] A kind of anti-friction and anti-pilling pure wool yarn, the pure wool yarn is a single yarn or a ply yarn spun from several wool fibers, the wool fibers are ultra-fine wool fibers, and the ultra-fine wool fibers are treated with antibacterial and antibacterial agents. Antibacterial wool fiber and antistatic wool fiber are formed after electrostatic agent treatment, and described pure wool yarn comprises mass parts 50 parts of antibacterial wool fiber, 40 parts of antistatic wool fiber, 40 parts of original superfine wool fiber, and described pure wool yarn surface coating Has a silicone coating.

[0059] The ply count of the pure wool yarn is a single yarn count of 175 and a ply yarn count of 185 / 3. The average diameter of the superfine wool fibers is 16.5 μm, the fineness is 145 s, and the length is 105 mm. The average linear density of the superfine wool fiber is 0.07dtex.

[0060] The above-mentioned pure wool yarn is made by the following processing technology: ...

Embodiment 3

[0081] A kind of anti-friction and anti-pilling pure wool yarn, the pure wool yarn is a single yarn or a ply yarn spun from several wool fibers, the wool fibers are ultra-fine wool fibers, and the ultra-fine wool fibers are treated with antibacterial and antibacterial agents. Antibacterial wool fiber and antistatic wool fiber are formed after electrostatic agent treatment, and described pure wool yarn comprises mass parts 30 parts of antibacterial wool fibers, 35 parts of antistatic wool fibers, 26 parts of original superfine wool fibers, and the surface of described pure wool yarn is coated with Has a silicone coating.

[0082] The strand count of the pure wool yarn is 170 common counts for single yarn and 182 / 3 common counts for ply yarns. The average diameter of the superfine wool fiber is 16 μm, the fineness is 140 s, and the length is 100 mm. The average linear density of the superfine wool fiber is 0.06dtex.

[0083] The above-mentioned pure wool yarn is made by the fo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com