Composite ester type nano refrigerating machine oil and preparation method thereof

A technology of refrigerating machine oil and double ester type, which is applied in the petroleum industry, base materials, lubricating compositions, etc. It can solve the problems of poor compatibility, poor viscosity-temperature performance, etc., and achieve excellent lubricating performance, good stability, and compatibility good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

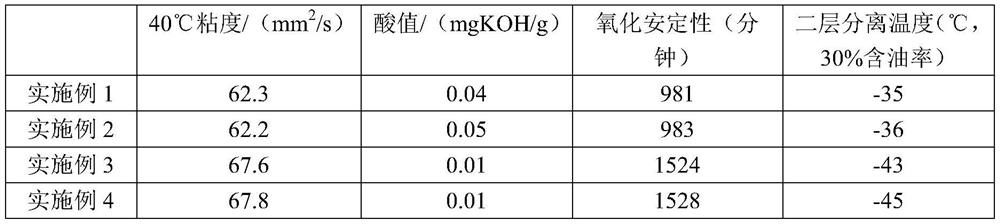

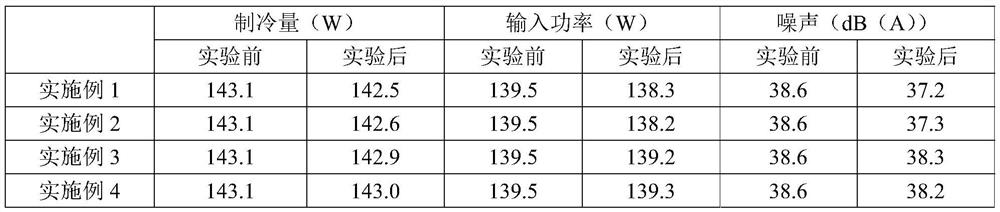

Examples

Embodiment 1

[0037] A kind of preparation method of complex ester type nanometer refrigerating machine oil, concrete steps are as follows:

[0038] (1) 530.6g diethylene glycol, 438.4g adipic acid, 4.4g nano-zinc oxide and 153.4g toluene are mixed to carry out the first step esterification;

[0039] (2) Then add 865.2g isooctanoic acid, carry out the second step esterification reaction, obtain reaction product;

[0040] (3) Finally, the reaction product is refined to obtain the double ester type nano-refrigeration machine oil.

[0041] In step (1), the first step of the esterification reaction is carried out under the protection of high-purity nitrogen, and the nitrogen flow rate is 20mL / min.

[0042] In the step (1), the process condition of the first step esterification reaction is: 130° C. for 150 minutes of stirring reaction.

[0043] In the step (2), the process condition of the second step esterification reaction is: 190° C. stirring for 100 minutes.

[0044] In step (3), the spec...

Embodiment 2

[0046] A kind of preparation method of complex ester type nanometer refrigerating machine oil, concrete steps are as follows:

[0047] (1) 636.7g of diethylene glycol, 438.4g of adipic acid, 6.5g of nano-alumina and 197.2g of petroleum ether were mixed for the first step of esterification;

[0048] (2) Then add 1297.8g isooctanoic acid, carry out the second step esterification reaction, obtain reaction product;

[0049] (3) Finally, the reaction product is refined to obtain the double ester type nano-refrigeration machine oil.

[0050] In step (1), the esterification reaction in the first step is carried out under the protection of high-purity nitrogen, and the nitrogen flow rate is 80mL / min.

[0051] In step (1), the process condition of the first step esterification reaction is: 180° C. for 170 minutes of stirring reaction.

[0052] In step (2), the process condition of the second step esterification reaction is: 230° C. for 120 minutes of stirring reaction.

[0053] In s...

Embodiment 3

[0055] A kind of preparation method of complex ester type nanometer refrigerating machine oil, concrete steps are as follows:

[0056] (1) 600g of diethylene glycol, 438.4g of adipic acid, 5.5g of metal oxide nanomaterials and 180g of xylene were mixed for the first step of esterification;

[0057] (2) Then add 1000g isooctanoic acid, carry out the second step esterification reaction, obtain reaction product;

[0058] (3) Finally, the reaction product is refined to obtain the double ester type nano-refrigeration machine oil.

[0059] In step (1), the metal oxide nanomaterial is prepared by the following method:

[0060] (A) First ultrasonically disperse 0.003g graphene oxide in 20g deionized water, then add 10g0.04mol / L manganese nitrate solution, 3g0.008mol / L cerium nitrate solution, continue ultrasonic dispersion evenly, and then slowly Add 28% ammonia solution dropwise until pH = 10, add 0.15g sodium borohydride, stir and react at 85°C for 3 hours, centrifuge to collect t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com